The Tube Mill Making Machine is a vital component in modern manufacturing. It has gained significant traction in producing high-quality tubes and pipes. According to recent industry reports, the global tube mill market is projected to grow at a CAGR of 5.2% from 2021 to 2026. This growth reflects the increasing demand for steel and metal products in various sectors.

The machine works by forming flat steel strips into cylindrical shapes. It then welds the edges and trims them to size. This process is both efficient and effective for mass production. However, not all machines are created equal. The quality of the output can vary based on the machine's specifications and maintenance. Reliability issues may arise when machines are not properly serviced.

Understanding the operation and applications of the Tube Mill Making Machine is crucial for manufacturers. It can lead to better productivity and product quality. Yet, manufacturers must acknowledge the need for continuous improvement and regular upgrades. The industry is fast-evolving, and staying competitive involves embracing technological advancements.

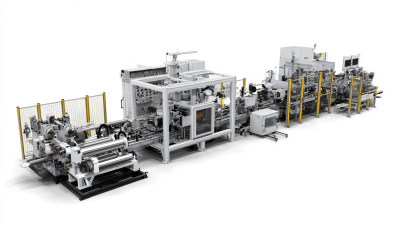

A tube mill making machine is an essential equipment in the manufacturing industry. It produces metal tubes and pipes through a series of processes. The machine utilizes coils of metal sheet, which are fed into the mill. These coils undergo a series of shaping and welding steps to form the final product. The tube mill's efficiency depends on its design and the materials used.

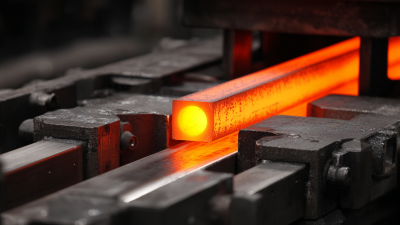

During operation, the metal coils are rolled through various rollers. Each roller gradually shapes the coil into a tube. After forming, the edges are welded to join them securely. This process can create tubes of different sizes and thicknesses, suitable for various applications. The quality of the weld is important. A poor weld can weaken the tube.

**Tips:** Always maintain your tube mill to ensure high performance. Regular cleaning can prevent buildup and malfunctions. Consider using different materials for enhanced durability.

Choosing the right settings for speed and pressure is crucial. Too fast may lead to defects. It's okay to take your time to adjust and find the best parameters. Experimentation might be needed. Documenting these settings can help in future productions.

This bar chart represents the monthly production output of a tube mill making machine over a six-month period. The steadily increasing production figures indicate an improvement in efficiency and capacity.

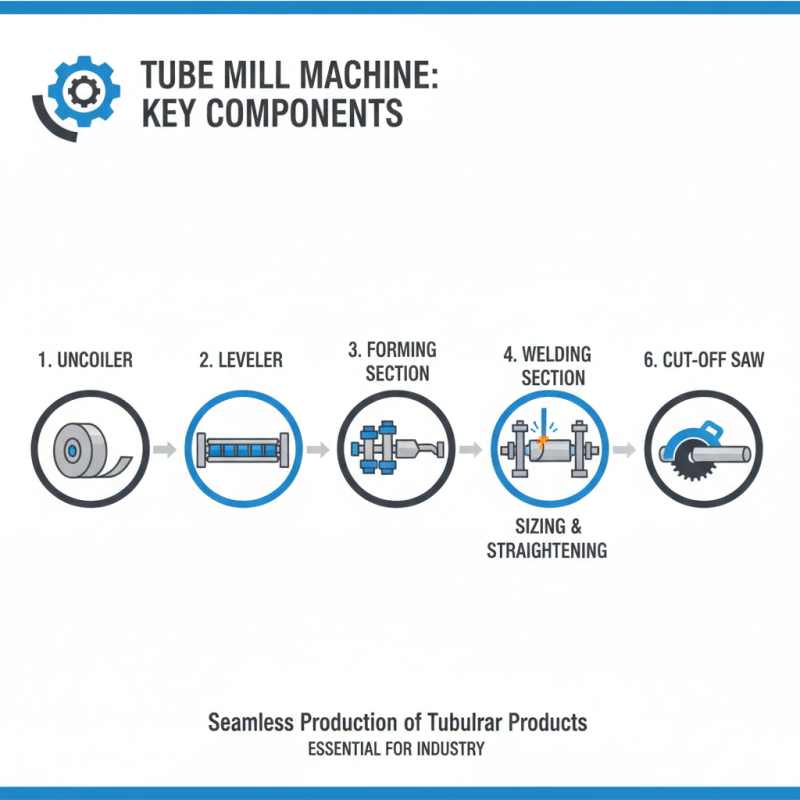

A tube mill making machine is essential for producing various tubular products. These machines are equipped with key components that work together seamlessly. Understanding these components is crucial for anyone in the industry.

The main component is the forming section. It shapes flat metal strips into tubes. Rollers and dies are used to guide the metal through the process. Consistency in this section ensures the final product maintains desired dimensions. Another important part is the welding section. Here, edges of the tube are fused together. High-frequency welding technology is often employed. This creates strong seams while minimizing distortion.

Tips: Regular maintenance of the forming and welding sections is vital. Look for wear and tear on rollers and dies. A quick inspection can prevent larger issues later.

The cutting section follows, where the tubes are cut to specified lengths. Precision is key here. Accurate cutting leads to better production efficiency. An imperfect cut can lead to wasted materials. Operators must check settings regularly to ensure they are aligned correctly.

Tips: Always calibrate cutting tools before starting a production run. This small step can save a lot of resources in the long run. Pay attention to any unusual noises during operation. They could indicate underlying problems.

A tube mill making machine is essential in metalworking industries. It efficiently produces welded tubes from coils of sheet metal. It's fascinating how this machine operates with intricate mechanical precision.

At its core, the working principle involves rolling and welding. A strip of metal is fed into rollers that shape it into a tube. The edges are then heated and pressed together, often using high-frequency induction. This method ensures a strong weld. In 2020, the global tube mill market was valued at approximately $1.1 billion, with projections suggesting growth to roughly $1.5 billion by 2026. The demand for higher-strength materials drives this expansion.

Despite its effectiveness, challenges exist. Proper alignment during welding is crucial. Misalignment can lead to defects. Additionally, choosing the right type of metal impacts the final product's durability. Some operators encounter issues with inconsistent weld quality. Regular maintenance is essential to avoid downtime and ensure productivity. Understanding these nuances can lead to improved outcomes in tube production.

| Feature | Description |

|---|---|

| Type | Tube Mill |

| Materials Used | Steel, Stainless Steel, Aluminum |

| Production Capacity | Up to 100 meters per minute |

| Thickness Range | 0.2 mm to 5 mm |

| Diameter Range | 10 mm to 500 mm |

| Working Principle | Roll-forming process to shape flat sheets into tubes |

| Applications | Construction, Automotive, HVAC, Furniture |

| Automation Level | Fully automated with PLC control |

| Maintenance | Regular lubrication and alignment checks recommended |

| Energy Consumption | Approximately 10 kWh per ton of product |

Tube mill making machines play a vital role in various industries. They produce cylindrical tubes used across multiple sectors. These machines efficiently create tubes from raw materials, often in high volumes. Manufacturing processes can differ based on specific requirements.

In construction, tube mills provide essential components for structures. The robust steel tubes are used for frameworks, scaffolding, and fencing. Their strength and durability make them ideal for these applications. This industry often demands quick production and precision.

Tube mills are also important in the automotive sector. They manufacture exhaust pipes and structural components. The efficient formation of pipes ensures that they meet safety and performance standards.

Tips: Regular maintenance of tube mills enhances their lifespan. Operators should regularly check for wear and tear. Proper lubrication can prevent unexpected downtimes.

Another industry utilizing tube mill making machines is energy. Tubes are needed for oil and gas pipelines. The quality of these tubes is crucial, as they must withstand high pressures. Manufacturers face challenges in ensuring consistent quality in such products.

Tips: Implementing quality control measures can reduce defects. Consistent monitoring of raw materials will improve final outputs. Companies should invest in training their workforce for better results.

Tube mill making machines play a significant role in manufacturing. These machines create tubes from metal sheets by rolling them and welding the edges. This process can produce a range of tube sizes and shapes. Manufacturers appreciate the flexibility offered by tube mills. They can easily switch between different sizes, which enhances production efficiency.

Using tube mill making machines brings various benefits. For starters, they enhance productivity. The continuous production flow minimizes downtime between jobs. Workers can focus on other tasks while the machine operates. Additionally, tube mills can achieve high precision in dimensioning. This ensures the finished products meet exact specifications. However, attention to maintenance is needed to avoid costly breakdowns. Regular checks are essential to ensure all components function properly.

Moreover, these machines are cost-effective over time. Initial investments can be substantial, but they often pay off through reduced labor costs and material waste. Yet, not all operations may find tube mills ideal. Some specialized products may require different processes. Adapting the machine settings for various materials can sometimes be challenging. Understanding these complexities can help manufacturers make informed decisions about their production needs.