The world of Square Tube Mill Pipe Making Machinery is vast and intricate. This machinery is vital for many industries, producing essential pipe products. Understanding its complexities can be daunting for newcomers and veterans alike.

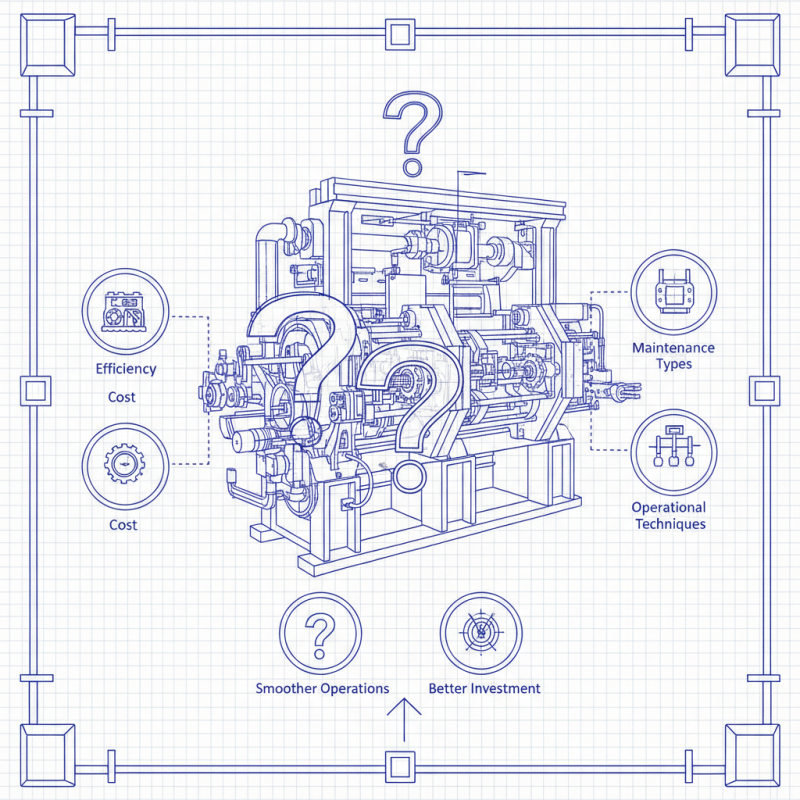

Often, people overlook the significant factors that impact production quality. Choosing the right machine is only the beginning. Users must also consider maintenance, material types, and operational techniques. Without a solid grasp of these components, one might face unforeseen challenges.

Many questions arise around efficiency, cost, and durability. How does one maximize output while minimizing waste? What are the common pitfalls in operation? These queries deserve careful contemplation. The right answers can pave the way for smoother operations and better investment returns. Exploring these topics helps demystify the machinery and empowers users to make informed decisions.

Understanding square tube mill pipe making machinery is vital in modern manufacturing. This technology plays a significant role in various industries such as construction, automotive, and energy. As the demand for square tubes increases, so does the need for efficient machinery. According to a report by MarketsandMarkets, the square tube market is expected to grow significantly due to rising applications across multiple sectors.

Square tube mill pipe making machinery offers precision and speed. These machines can produce high-quality tubes in various sizes. They are equipped with advanced technology to ensure that each tube meets industry standards. However, not all machines are created equal. Some models may produce inconsistent results, leading to waste. It's crucial to choose machinery carefully, focusing on reliability and efficiency.

Tip: Regular maintenance can prevent unexpected breakdowns. This extends the life of the machinery and ensures consistent output. Understanding the specific needs of your production process will help in selecting the right equipment.

Choosing the right mill can feel overwhelming. Keep in mind the balance between cost and quality. Investing in quality machinery may yield better long-term results, but it's essential to analyze your production needs. Would cutting corners on equipment lead to more issues down the line? Reflecting on this might save resources in the future.

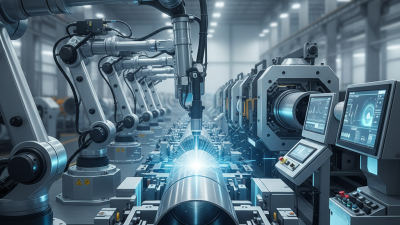

Square tube mill machinery plays a crucial role in manufacturing. Understanding its key components is essential for efficiency. The primary parts include the forming machine, cutting machine, and welding unit. Each component must work in harmony to optimize production.

The forming machine shapes the flat strip into a square tube. This process includes several rollers and adjustments, which need precise calibration. A study by the Machinery Manufacturers Association found that improper calibration can lead to a 15% decrease in production efficiency. Regular maintenance checks are vital.

Welding units are equally significant. They apply heat to join edges, creating a strong bond. Common methods include TIG and MIG welding. However, many factories overlook the importance of proper cooling systems. Without effective cooling, weld integrity may suffer.

Tips: Invest in automated systems. They minimize human error, boosting productivity. Additionally, training staff on component functionality enhances understanding. It reduces mistakes in operations. Overall, focusing on these components can improve overall manufacturing processes.

| Question | Answer | Key Component | Function |

|---|---|---|---|

| What is a square tube mill? | A machine used to create square and rectangular tubes from flat steel. | Forming Rolls | Shape the flat steel into a tube. |

| What materials can be used? | Typically mild steel, stainless steel, and aluminum. | Material Feed System | Facilitates the steady supply of material. |

| What is the purpose of a welding station? | To join the edges of the tube during production. | Welding Head | Ensures strong, continuous joints. |

| How is tube size adjusted? | Using interchangeable forming rolls. | Roll Change System | Allows for quick size setup changes. |

| What technology is used for cutting? | Laser or shear cutting systems. | Cutting Unit | Provides precise tube lengths. |

| How is quality ensured? | Through in-line inspection and testing. | Quality Control Station | Verifies product meets specifications. |

| What is the typical production speed? | Depending on the machine, typically 30-150 m/min. | Drive System | Controls the speed of production. |

| Is customization available? | Yes, many machines can be tailored for specific needs. | Customization Features | Enhances machine versatility. |

| What maintenance is required? | Regular cleaning and lubrication of parts. | Maintenance Kit | Tools for routine upkeep. |

| How are the tubes packaged? | Typically bundled and strapped for safety. | Packaging System | Prepares finished products for shipping. |

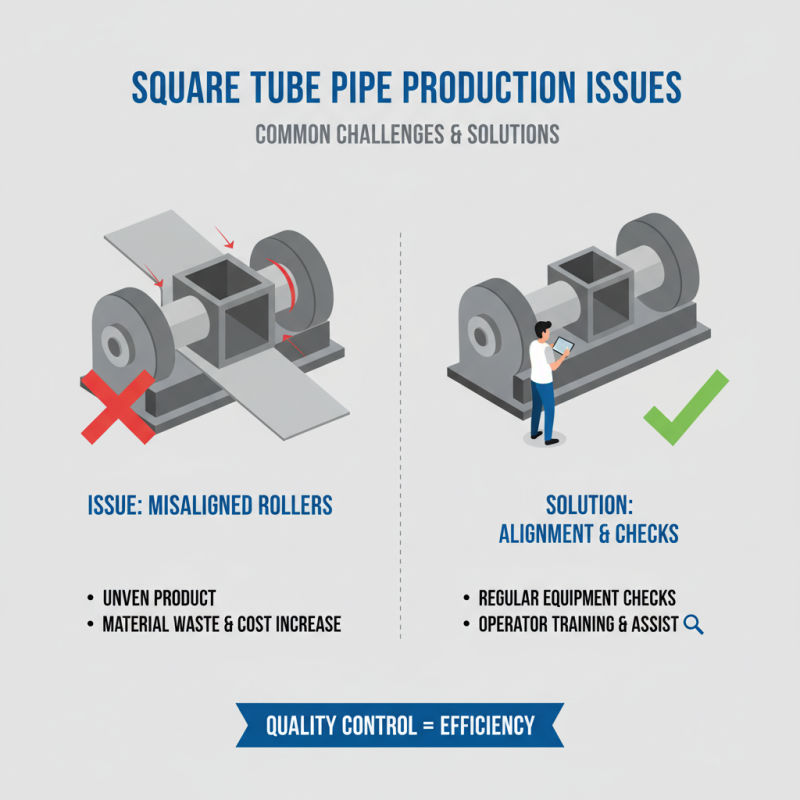

In the production of square tube pipes, several common issues can arise. One frequent challenge is the alignment of the machinery. If the rollers are misaligned, the final product may come out uneven. This problem can lead to wasted materials and increased costs. Regular checks on the equipment can help, but even experienced operators can overlook subtle misalignments.

Another pressing issue is the quality of the raw materials. Using low-quality steel can result in weak pipes, which may not meet industry standards. It's easy to cut corners here, but it can have serious consequences. Operators often face pressure to minimize costs, yet this can compromise the integrity of the final product. Attention to detail in sourcing materials is crucial but sometimes neglected.

Lastly, the speed of production can affect the final outcome. Rushing through the process leads to mistakes. Operators may overlook small defects or skip quality checks. Striking a balance between efficiency and product quality is a challenge that requires constant reflection. Regular training for operators can improve outcomes but is often under-prioritized in busy production settings.

Maintenance of square tube mill machinery is crucial for optimal performance. Regular checks keep the equipment running smoothly. According to a recent industry report, approximately 70% of machine failures stem from inadequate maintenance practices. Simple tasks, such as lubricating components, can make a significant difference. Ensure that all moving parts are well oiled. This can extend the lifespan of the equipment.

Another area to focus on involves monitoring the alignment of the machinery. Misalignment can lead to uneven wear and tear. It is suggested that operators assess alignments weekly. Dust and debris can accumulate over time, affecting performance. Regular cleaning is essential, yet often overlooked. A clean machine operates more efficiently, reducing energy costs.

Operators should also examine the cooling systems. Overheating can cause extensive harm. Data shows that severe overheating incidents can lead to costly repairs. Scheduling routine inspections can prevent this issue. Awareness of these maintenance factors is key. Neglecting them may result in unexpected downtimes and financial strain. This critical maintenance can ensure that square tube mills perform reliably over time.

The advancements in square tube pipe making technology are remarkable. Automated systems now dominate the industry. These machines enhance productivity significantly. With integrated controls, the precision in forming is unmatched. They guarantee that each tube meets specific standards. This reduces waste and optimizes efficiency.

Innovation doesn't stop there. Materials used in production are evolving. New alloys provide better strength and durability. However, some machinery struggles to adapt to these changes. Operators need ongoing training, which can be a challenge. Enhancing skills is necessary, but the industry's fast pace makes it hard.

There are concerns about environmental impacts as well. Energy consumption remains high in many plants. While new machines claim efficiency, the reality can be different. The industry should reflect on sustainable practices. Balancing innovation and responsibility is essential for future success.