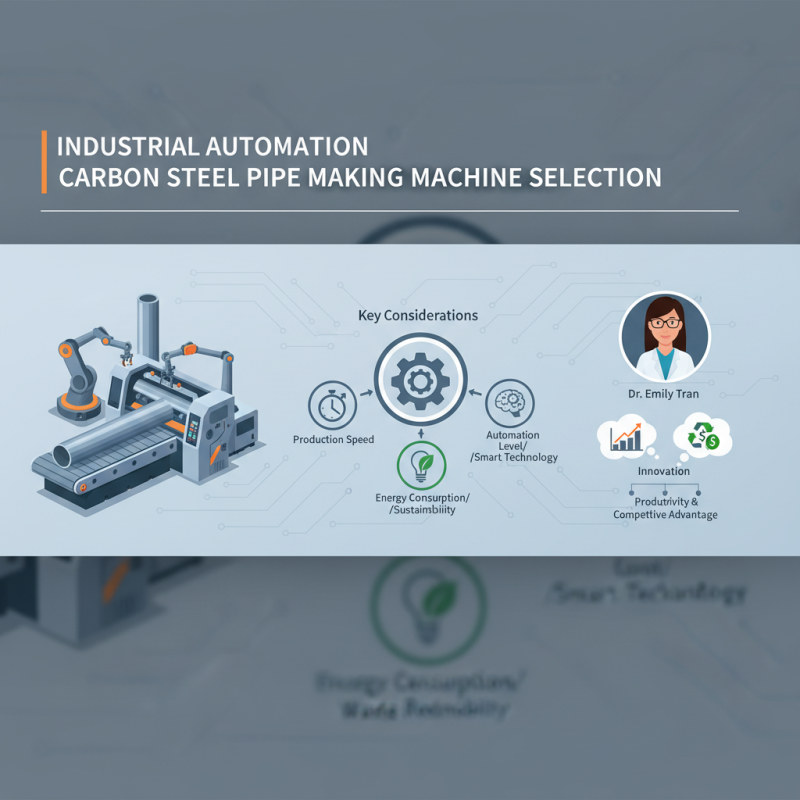

In today's ever-evolving manufacturing landscape, the selection of the right machinery is crucial for achieving operational efficiency and product quality. One of the pivotal machines in this domain is the Industrial Automation Carbon Steel Pipe Making Machine. According to Dr. Emily Tran, a leading expert in industrial automation, “The right pipe making machine not only enhances productivity but also minimizes waste, which is essential for sustainable manufacturing practices.”

As industries strive to optimize production processes and reduce costs, understanding the features and capabilities of an Industrial Automation Carbon Steel Pipe Making Machine becomes increasingly essential. Companies often find themselves overwhelmed by the plethora of options available, making it vital to evaluate parameters such as production speed, energy consumption, and automation level.

Moreover, with the rise of smart manufacturing, integrating advanced technologies into pipe-making machines can significantly impact performance. Dr. Tran emphasizes, “Embracing automation and smart technologies in pipe manufacturing is not just a trend; it’s becoming a necessary strategy for competitive advantage.” By carefully considering these factors, businesses can make informed decisions that will enhance their production lines and contribute to long-term success in the industrial sector.

The production of carbon steel pipes plays a crucial role in various industrial sectors, including construction, oil and gas, and manufacturing. Understanding how carbon steel pipe making machines operate is essential for selecting the most suitable equipment for your needs. These machines are designed to shape and weld steel into pipes of varying diameters and thicknesses, utilizing advanced technologies to ensure precision and efficiency. According to a report by the International Automation Association, the demand for carbon steel pipes is expected to grow at a CAGR of 4.5% through 2025, underscoring the importance of investing in quality machinery.

When choosing a carbon steel pipe making machine, it is important to consider the type of production you require. For instance, high-frequency induction welding (HFIW) machines are commonly used for producing thinner pipes, while submerged arc welding (SAW) machines are preferred for thicker materials. Additionally, ensuring that the machine has capabilities for various pipe sizes can enhance versatility and production efficiency.

Tips: Assess your production needs by determining the pipe specifications and output requirements. This will help identify the type of machine best suited for your operations. Moreover, investing in modern machines equipped with automation features can significantly reduce labor costs and increase overall productivity, as highlighted by a recent study showing a 30% decrease in production time with automated systems.

When selecting an industrial automation carbon steel pipe making machine, it's essential to consider several key features that can greatly influence the machine's efficiency and output quality. One of the primary aspects to evaluate is the machine's production capacity. This includes the speed of operation, the maximum pipe size it can handle, and its ability to produce various pipe grades. A machine with higher throughput can significantly enhance productivity, allowing manufacturers to meet demand without compromising quality.

Another critical feature to look for is the level of automation and control technology integrated into the machine. Advanced automation systems not only streamline operations but also reduce the risk of human error. Look for machines equipped with user-friendly interfaces, real-time monitoring capabilities, and programmable logic controllers (PLCs) that facilitate precise adjustments. Moreover, features such as predictive maintenance options can increase the machine's longevity and decrease downtime, ensuring consistent operation in a production environment.

Finally, consider the build quality and the materials used in constructing the machine. A robust design, along with high-quality components, ensures reliability and durability, especially in heavy-duty applications. It’s also vital to assess the machine's energy efficiency and overall operational costs, as these factors contribute to long-term profitability. With these considerations in mind, manufacturers can make more informed decisions when investing in an industrial automation carbon steel pipe making machine, ultimately optimizing their production processes.

| Feature | Description | Importance |

|---|---|---|

| Pipe Diameter Range | The range of diameters that the machine can produce. | High - Affects product versatility. |

| Automation Level | Extent to which the machine is automated, including control systems. | Critical - Determines production efficiency. |

| Material Compatibility | Types of materials the machine can work with, specifically carbon steel. | Essential - Ensures endurance and quality of pipes. |

| Production Speed | Maximum number of pipes produced in a specified time frame. | Important - Impacts overall production output. |

| Energy Efficiency | Measures the energy consumption relative to output. | Value - Reduces operational costs. |

| Maintenance Requirements | The level of maintenance needed to keep the machine operational. | High - Affects downtime and service costs. |

| Safety Features | Built-in safety measures to protect operators and equipment. | Critical - Essential for workplace safety. |

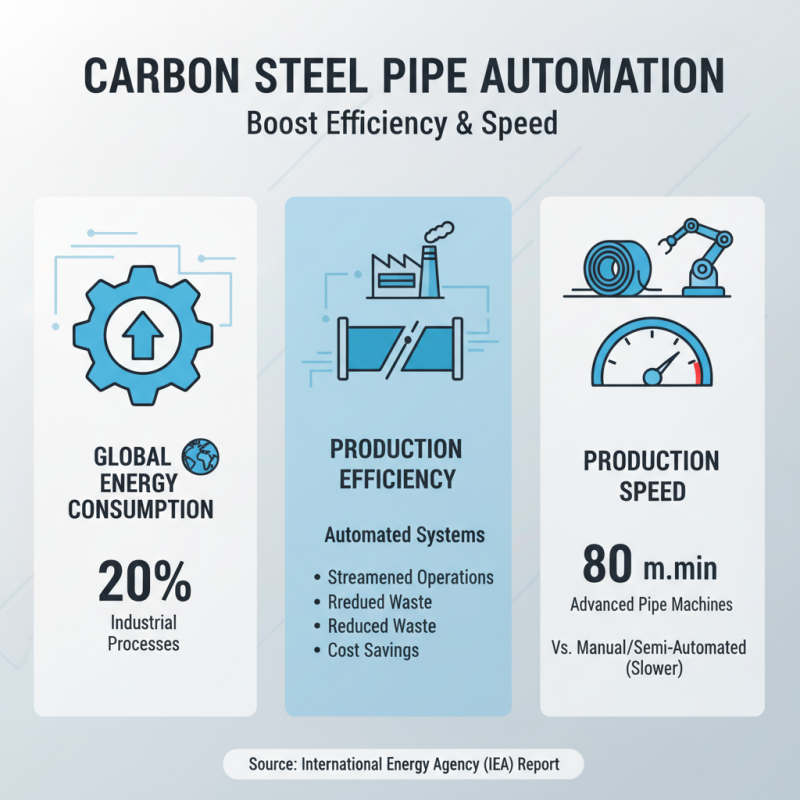

When considering industrial automation for carbon steel pipe production, evaluating production efficiency and speed is crucial. According to a report by the International Energy Agency (IEA), industrial processes account for approximately 20% of global energy consumption, indicating that optimizing these processes can lead to significant cost savings and improved productivity. In the context of pipe manufacturing, efficiency can be enhanced through automated systems that streamline operations and reduce waste. Advanced carbon steel pipe making machines can achieve production speeds of up to 80 meters per minute, significantly surpassing those of manual or semi-automated processes.

Moreover, a study published in the Journal of Manufacturing Processes suggests that integrating automation not only increases speed but also enhances product quality by minimizing human error. Automated machines equipped with precision controls can maintain tighter tolerances, essential for applications in demanding industries such as oil and gas. The report highlights that manufacturers who adopt cutting-edge automation technologies can experience a productivity increase of 30% to 50% compared to traditional manufacturing methods, thereby reinforcing the importance of selecting the right equipment for maximizing production efficiency. Investing in advanced automation technology is not just about speed; it is also about ensuring long-term competitiveness in the industrial sector.

When evaluating different brands and models of carbon steel pipe making machines, it's crucial to consider several key factors that determine their efficiency and suitability for industrial applications.

First, analyze the production capacity and speed of each machine. Different models may offer varied output rates, significantly impacting your production timelines. Additionally, look into the technology utilized by these machines. Models that incorporate advanced automation features often result in higher precision, reduced human error, and increased overall productivity.

Another important aspect to compare is the durability and maintenance requirements of the machines. Carbon steel pipe making machines are typically subjected to high levels of stress and wear, so investing in a model that is built with robust materials can lead to long-term savings on repair and replacement costs. Check user reviews and feedback on the reliability of different brands, as well as the availability of spare parts and support services.

Lastly, consider the overall cost of ownership, which includes initial investment, operating costs, energy efficiency, and potential for upgrades, to ensure you select a machine that meets both your financial and production needs.

When selecting an industrial automation carbon steel pipe making machine, understanding the long-term costs and maintenance requirements is crucial for ensuring operational efficiency and sustainability. The initial purchase price is just one component of a machine's overall cost. To make a well-informed choice, it's essential to consider ongoing expenses such as energy consumption, raw material costs, and labor. Machines that are energy-efficient and require less material waste can provide significant savings over time.

Maintenance requirements also play a vital role in the long-term viability of your machinery. A machine that is easy to maintain can reduce downtime and repair costs, enhancing overall productivity. Look for equipment with accessible parts and standardized specifications, which can simplify maintenance procedures and decrease reliance on specialized technicians. Additionally, consider the availability of replacement parts and the manufacturer’s support services, as these factors can affect your operational continuity and costs in the long term.