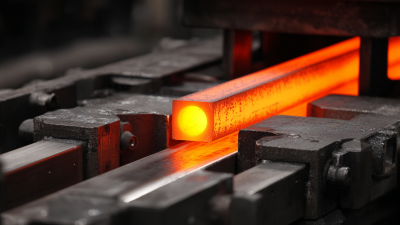

In the world of manufacturing, efficiency is key. Ms Tube Mill Pipe Making Machinery has emerged as a vital tool for pipe production. This machinery offers numerous advantages that revolutionize the industry. Its design focuses on speed and precision, allowing productions to meet high demands.

These machines provide flexibility in production. The ability to create various sizes and shapes helps cater to diverse project needs. However, it's essential to consider maintenance challenges that may arise. While these machines enhance productivity, proper care is vital to avoid costly downtimes.

Investing in Ms Tube Mill Pipe Making Machinery can significantly boost output. Companies are increasingly recognizing the importance of this technology. However, one must reflect on the balance between innovation and machine upkeep. When utilized effectively, this machinery can pave the way for advanced manufacturing success.

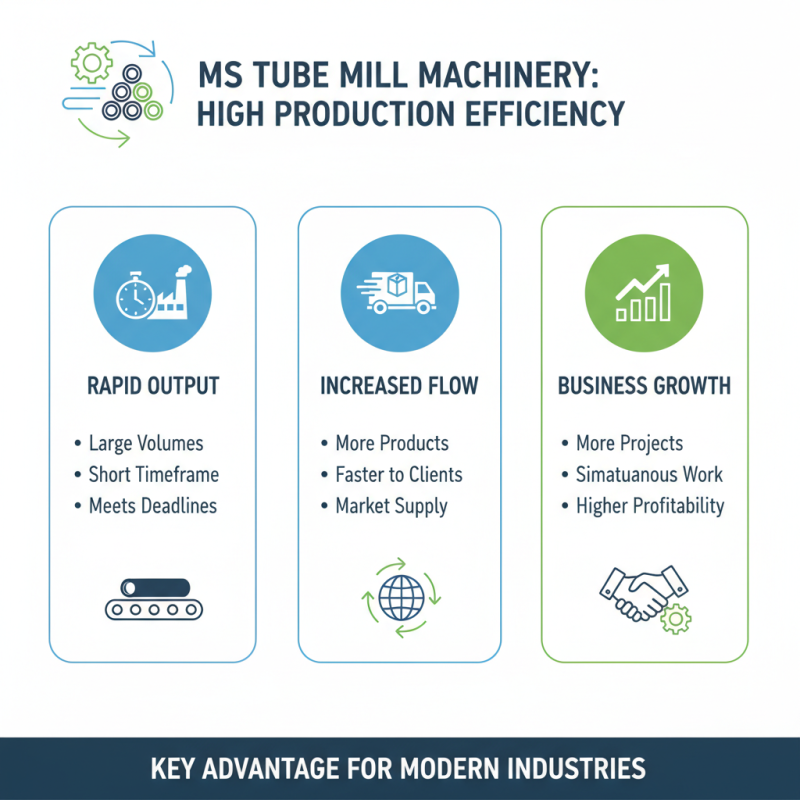

High production efficiency is a significant advantage of MS tube mill machinery. This equipment can produce large volumes of pipes in a short time. Industries often face tight deadlines, and this machinery helps meet demands. Faster production means more products flowing out for clients. When production rates increase, businesses can tackle more projects simultaneously.

The machinery operates with remarkable precision. Each pipe is made to exact specifications, reducing the need for rework. However, maintaining precision requires regular checks and adjustments. Neglecting this can lead to quality issues. While the first runs may be flawless, it's crucial to monitor consistency over time.

Using MS tube mills can streamline operations. Automated processes reduce manual labor, but this can lead to complacency. Workers need to stay alert and engaged with the machines. Relying too heavily on automation can sometimes backfire. Mistakes can occur if operators aren't attentive. Regular training is essential for maximizing efficiency and minimizing errors.

In modern pipe manufacturing, efficiency is key. MS tube mill machinery offers significant cost savings in labor and materials. Traditional methods often involve excess material use, leading to waste. With advanced machinery, the precision in cutting and shaping minimizes this waste. Each pipe produced can maximize the use of raw materials, which is a game-changer.

Labor costs are also reduced. Automated processes mean fewer workers are needed for tasks that once required a full team. This shift can lead to a leaner operation. However, the initial investment in such machinery can be daunting for smaller manufacturers. It's crucial to weigh these costs against long-term savings. Companies must consider whether the upfront expense justifies the reduced waste and labor needs. Balancing immediate financial pressures with potential future gains is not always straightforward. The technology must be well-implemented to avoid issues in production consistency.

In the world of pipe production, advanced technology plays a crucial role. Enhanced quality control is one of the top benefits of Ms Tube Mill Pipe Making Machinery. This technology helps in minimizing defects and maximizing output. For instance, precision sensors monitor the entire process. This ensures that every pipe meets the strict standards required for various applications.

Automation is another significant aspect. It reduces human error during manufacturing. Workers are less stressed and can focus on other crucial tasks. Systems are set to automatically adjust based on real-time data. This means fewer interruptions and higher efficiency. However, the complexity of this machinery can be overwhelming. Proper training and ongoing maintenance are necessary to keep everything running smoothly.

**Tips:** Regularly train your staff on new features. This keeps everyone updated and ensures quality. Keep an eye on data trends. They can reveal potential issues before they become problems. Advanced technology is great, but it requires careful handling. Continuous learning and adaptation are key to any successful operation in this field.

| Benefit | Description | Impact Level |

|---|---|---|

| Enhanced Quality Control | Utilizes advanced monitoring systems to ensure product consistency. | High |

| Cost Efficiency | Reduces production costs through efficient material usage. | Medium |

| Increased Production Speed | Advanced technology allows for faster manufacturing cycles. | High |

| Flexibility in Design | Supports customization in pipe dimensions and specifications. | High |

| Durability of Products | Manufactures pipes with enhanced strength and longevity. | High |

| Sustainability | Uses eco-friendly materials and processes to reduce waste. | Medium |

| Rapid Prototyping | Enables quick development of pipe prototypes for testing. | High |

| Operator Safety | Incorporates safety features to protect operators during use. | High |

| Maintenance Ease | Designed for straightforward maintenance and troubleshooting. | Medium |

| Technological Integration | Integrates modern technologies for enhanced performance. | High |

The MS Tube Mill is a remarkable tool in the pipe manufacturing industry. It offers versatility in creating various pipe sizes and materials. According to industry reports, the global demand for stainless steel pipes is projected to reach 10 million tons by 2025, indicating a clear need for adaptable machinery.

With its ability to handle different materials, the MS Tube Mill serves diverse applications. Steel, aluminum, and copper can all be formed efficiently. This flexibility allows manufacturers to cater to different market segments. The output can range from small diameter pipes to larger ones, addressing specific customer needs. However, mastering such versatility requires skilled operators familiar with the machinery’s capabilities.

Moreover, while the MS Tube Mill is advantageous, it presents challenges. The setup process can be time-consuming, affecting production speed. Additionally, not all materials yield the same results, leading to potential waste. Analyzing performance across different materials helps refine processes over time. The industry's evolution shows that constant adaptation is necessary for maintaining efficiency.

This chart illustrates the top 10 benefits of MS Tube Mill Pipe Making Machinery. Each benefit is rated on a scale from 1 to 10, representing its impact and importance in pipe making.

Modern pipe mills are revolutionizing the way we think about manufacturing. Their impact on sustainability is profound. With advanced technology, these machines optimize material usage and minimize waste. This operational efficiency significantly lowers the carbon footprint.

Additionally, modern mills reduce energy consumption during production. This shift is vital as industries seek greener alternatives. However, transitioning to such technologies can be challenging. Initial costs and training may hinder small manufacturers. Yet, the long-term benefits often outweigh these hurdles. The ability to produce high-quality pipes with less environmental harm is worth pursuing.

Investing in modern pipe making machinery is not merely a trend. It reflects a commitment to responsible manufacturing. Each step towards sustainability helps the planet. This evolution requires continuous reflection and adaptation. Companies must remain open to improvement and innovation. Embracing such changes can lead to a more sustainable future for all.