Revolutionize steel manufacturing with automated mild steel pipe manufacturing machines

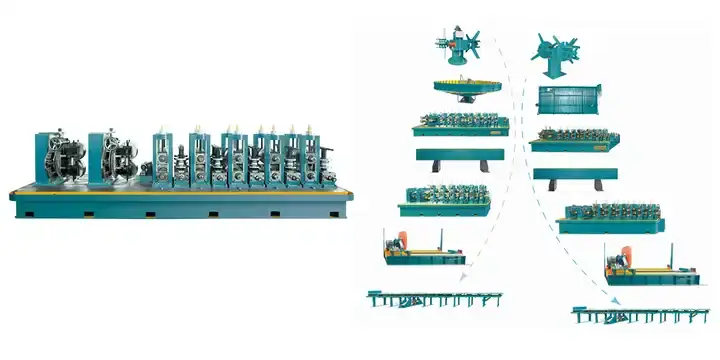

In the growing steel manufacturing industry, the introduction of automated mild steel metal pipe manufacturing machines marks a major advance in manufacturing technology. This state-of-the-art machine is specially designed to increase the efficiency of the production of low carbon steel tubes, the main products in a variety of industrial applications. By automating the entire manufacturing process - from the initial feeding of raw materials to the precise cutting of finished tubes - the machine not only simplifies the operation, but also ensures a high degree of consistency in product quality.

The automated low carbon steel pipe making machine is designed to meet the needs of modern steel manufacturing, where efficiency and yield are critical. By reducing dependence on labor, this advanced system greatly reduces labor costs while increasing productivity. Process automation minimizes human error, resulting in more reliable and consistent products. As the industry strives to optimize operations, integrating these machines is critical to staying competitive in a rapidly evolving market.

In addition, the benefits of automating mild steel metal pipe manufacturing machines go beyond cost savings and increased efficiency. The machine's ability to produce high-quality mild steel tubes has always made it a valuable asset to manufacturers seeking to enhance their product offerings. With the increasing demand for reliable and durable steel products, investing in advanced automation technologies is not only a trend, but also a strategic move for the sustainable growth of the steel manufacturing industry. Embracing innovation like this will undoubtedly pave the way for a more efficient and economical future for the industry.