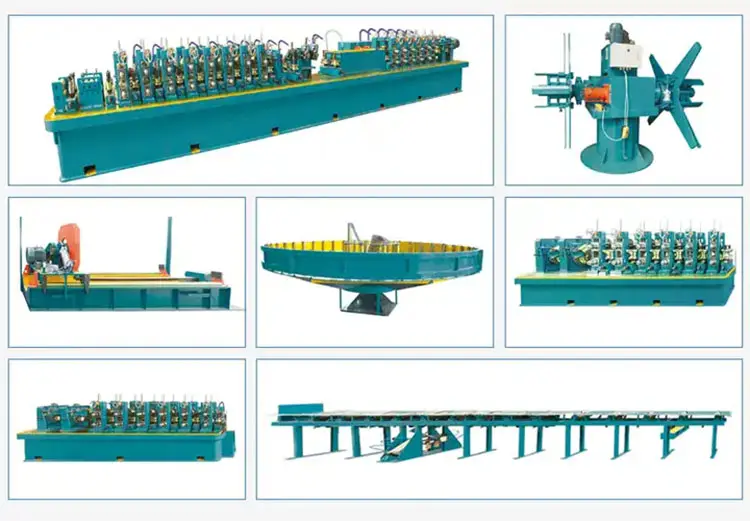

HF Welding Pipe Making Machines

High frequency welding pipe making machine is the key component of pipe production and has a wide range of applications. These machines use high-frequency energy to weld steel strips together to form pipes of various sizes and thicknesses. High frequency welding technology has proven to be cost-effective and reliable, making it a popular choice for pipe manufacturers worldwide.

The main advantage of high-frequency welding pipe making machines is that they can be used to produce pipes of various diameters and thicknesses with minimal installation time and no additional tools required. This makes them ideal for both small and large pipe manufacturing operations. In addition, high-frequency welders produce strong and reliable welds that are resistant to wear and ensure the life and durability of the pipes produced.

The machine uses induction coils to generate high-frequency energy that is used to heat the edge of the steel strip to be welded. The induction coil creates an electromagnetic field that creates an electric current in the steel strip, generating heat that melts the edges of the strip together. The weld is then formed by applying pressure to the heated area.

The high frequency pipe welding machine is designed to be efficient and user-friendly. They are equipped with a sophisticated electronic control system that allows the operator to closely monitor the welding process and make adjustments as needed. In addition, most machines are automated, which reduces the need for manual labor and increases production efficiency.

In short, high-frequency welded pipe manufacturing machines are an excellent investment for companies looking to produce high quality pipes in a cost-effective manner. These machines are versatile, efficient, and easy to operate, making them ideal for both small and large pipe manufacturing operations. With its reliable welding capabilities and ability to handle a variety of materials, high-frequency welders are bound to play a key role in the future of pipe manufacturing.