Art and Innovation of Pipe Making Machinery

Pipelines have been an integral part of human civilization for centuries, used for a variety of purposes such as transportation, irrigation, and most commonly to transport water and other fluids. While the concept of pipes may seem simple, the process of manufacturing them requires expertise, precision, and modern machinery. In this blog post, we will delve into the fascinating world of pipe manufacturing machinery and explore the art and innovation behind it.

Evolution of pipe making machinery:

Pipe manufacturing machinery has come a long way from its humble beginnings. In ancient times, pipes were mainly made of natural materials such as bamboo, clay, and even animal horns. However, as civilization progressed, there was a need for stronger and more durable pipes. This led to the development of various pipe making technologies and eventually to the development of modern pipe making machinery.

Modern pipe making machinery:

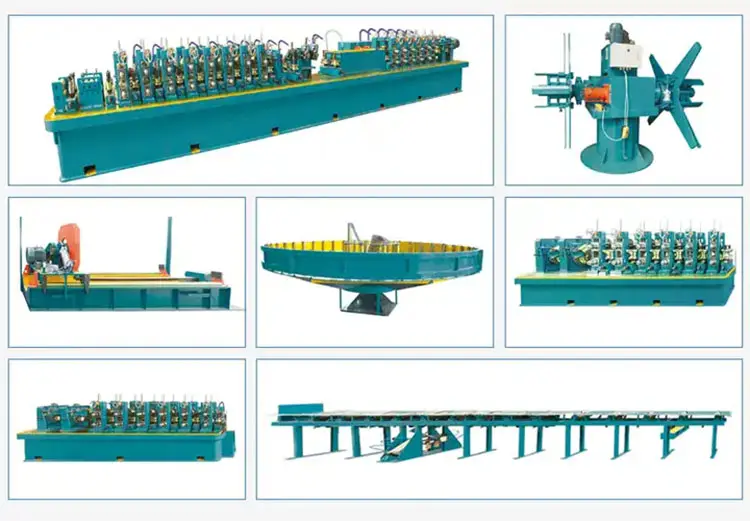

Today, pipe manufacturing machinery combines the principles of engineering, metallurgy and automation to produce pipes of exceptional quality, durability and precision. These machines use advanced technology to shape, cut and connect different materials, such as carbon steel, to form pipes of various sizes and dimensions. The integration of computer control and robotic systems further improves the efficiency and accuracy of the manufacturing process.

Innovation of pipe making machine:

One of the major innovations in pipe manufacturing machinery is the introduction of extrusion technology. The process involves heating raw materials such as carbon steel and forcing them through a mold to form pipes of the same shape and size. Extrusion technology has revolutionized the industry by allowing manufacturers to produce tubing quickly and cost-effectively. In addition, it can create complex pipeline designs that meet specific needs and applications.

Another important development is the use of computer-aided design (CAD) and computer-aided manufacturing (CAM) software in pipe manufacturing machinery. These software systems enable engineers to design complex pipeline structures with high precision and accuracy. They also help seamlessly integrate with manufacturing processes, reduce human error and ensure consistent output quality.

Process of pipe making machinery:

While pipe manufacturing machinery may seem like a purely technical process, there is an inherent artistry to the process. Engineers and designers must carefully balance function, beauty, and efficiency in their designs. They take into account factors such as pressure resistance, flow rate and environmental impact to create pipes that not only perform their intended function, but contribute to the overall beauty of the installation.

To sum up:

Pipe making machine is the perfect integration of ancient wisdom and modern technology. It combines engineering marvels with artistic sensibility, producing pipes that serve countless industries around the world. As we continue to grow, so does the art and innovation of pipe manufacturing machinery, ensuring we have the ability to build a strong infrastructure for future generations.