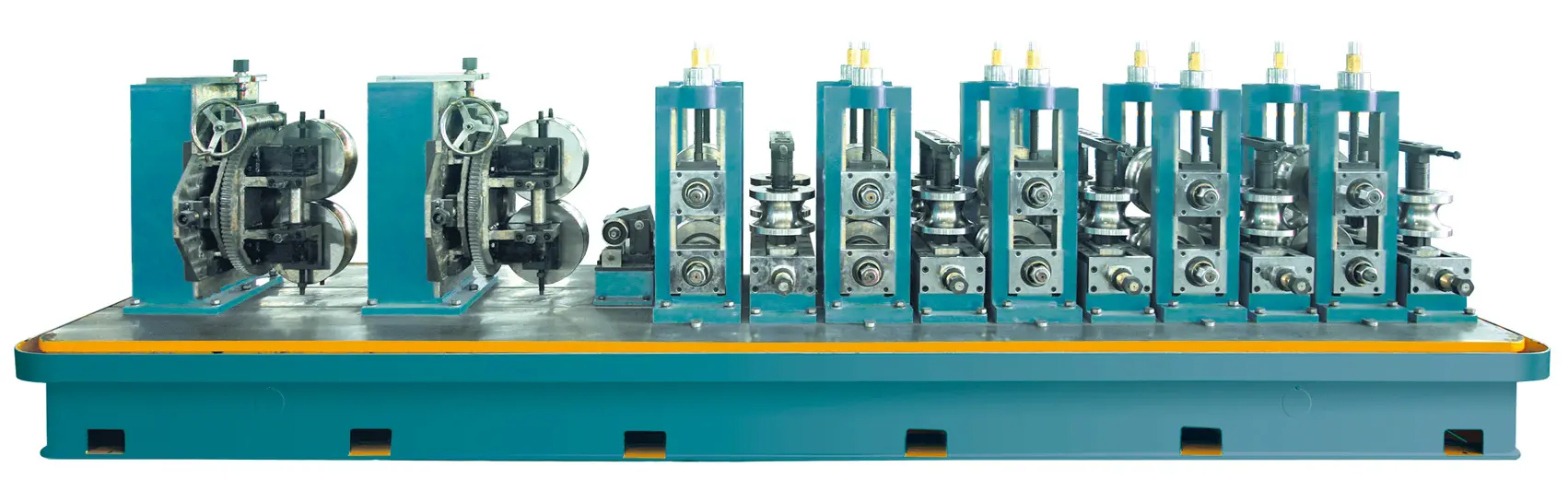

MG-50 Welded Steel Tube Mill Manufacturing Metal Pipe Making Machine

description2

Product Details

The square tube making machine has high efficiency and fast running speed. They are run automatically throughout the process, from feeding raw materials to cutting finished tubes. These machines have a variety of functions that enable them to produce a wide variety of square tubes of varying sizes. They can also make square tubes of different shapes and angles.

A distinguishing feature of these machines is their flexibility. They can produce square tubes of different materials, such as carbon steel. They can also handle a variety of thicknesses to produce tubes that meet the specific needs of the industry. The square tube making machine is also easy to operate. They come with user-friendly controls that provide an intuitive and easy-to-understand interface for the operator.

In short, the square tube manufacturing machine is an essential equipment in the manufacturing industry. They are efficient, easy to operate and versatile, providing the industry with high-quality square tubes in a variety of sizes, shapes and angles. The innovation and technology behind these machines have revolutionized the production of square tubes, enabling the industry to produce high quality and affordable products that meet market demand.

Pipe welding machines are designed for the production of round, square and rectangular pipes. The production line adopts roll pass design, can produce welded steel pipe, good processing quality, high assembly precision.

Pipe welding machine equipment is used to provide unaffected material between endpoints. Their shape and material provide inherent resistance to compression, which means they are the best choice for transporting fluid media (e.g. water, gas) through harsh environments without the risk of contamination. Pipes manufactured by pipe welding machines are also effectively used for wiring pipes, such as wires or ropes.

The integrity of pipes also makes them a key structural element in manufacturing pipes. Pipes manufactured by welding pipe machines are often integrated into load-bearing beams that can be used to assemble temporary structures such as scaffolding, effectively act as handrails, guardrails and flagpoles, and can even get niche jobs such as firefighters' poles.

description2

Machine Parameter

|

Item No.

|

MG-50

|

|

Outer Diameter

|

19mm-76mm

|

|

Wall Thickness

|

0.7mm-2.75mm

|

|

Square tube size

|

15×15mm~60×60mm

|

|

Square tube thickness

|

0.6mm~2.0mm

|

|

Production Speed

|

30-100m/min

|

|

Pipe length

|

4M~8M

|

|

Driving Motor

|

160KW*1 set

|

|

HF Welder Power

|

200KW

|

|

Weight

|

≤2500kg

|

|

Core Components

|

PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump

|

|

Warranty of core components

|

1 Year

|

|

Applicable Industries

|

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Retail, Construction works |

description2

Production Line

description2

Tube Mill Making Machine

| Model | Outer diameter | Pipe thickness | Square tube size | Square tube thickness | Produce speed |

| MG-16 | 7mm-25mm | 0.3mm-1.0mm | 10mm*10mm-20mm*20mm | 0.3mm-0.8mm | 30m-100m/min |

| MG-25 | 8mm-32mm | 0.4mm-1.2mm | 10mm*10mm-25mm*25mm | 0.4mm-1.0mm | 30m-100m/min |

| MG-28 | 10mm-50.8mm | 0.5mm-1.8mm | 10mm*10mm-45mm*45mm | 0.6mm-1.5mm | 30m-100m/min |

| MG-32 | 13mm-50.8mm | 0.6mm-2.0mm | 10mm*10mm-40mm*40mm | 0.6mm-1.5mm | 30m-100m/min |

| MG-45 | 13mm~60mm | 0.6mm-2.5mm | 10mm*10mm~45mm*45mm | 0.6mm~2.0mm | 30m-100m/min |

| MG-50 | 19mm-76mm | 0.7mm-2.75mm | 15mm*15mm-60mm*60mm | 0.6mm-2.0mm | 30m-100m/min |

| MG-60 | 25mm-80mm | 1.0mm-3.25mm | 20mm*20mm-50mm*50mm | 0.8mm-3.0mm | 30m-80m/min |

| MG-76 | 30mm-90mm | 1.0mm-4.0mm | 50mm*50mm-130mm*130mm | 1.5mm-4.0mm | 15m-70m/min |

| MG-127 | 32mm-127mm | 1.5mm-4.0mm | 50mm*50mm-130mm*130mm | 1.5mm-4.0mm | 20m-70m/min |

| MG-140 | 32mm-140mm | 0.8mm~4.0mm | 25mm*25mm-110mm*110mm | 0.8mm-3.5mm | 30m-70m/min |

| MG-165 | 50mm-165mm | 2.0mm-5.0mm | 25mm*25mm-100mm*100mm | 1.0mm-4.0mm | 30m-50m/min |

| MG-172 | 89mm-172mm | 1.0mm~5.0mm | 70mm*70mm~130mm*130mm | 1.0mm-4.0mm | 30m-70m/min |

| MG-219 | 76.2mm-219.1mm | 2.0mm~8.0mm | 60mm*60mm~170mm*170mm | 2.0mm-8.0mm | 30m-45m/min |

| MG-254 | 89mm-254mm | 2.0mm~7.0mm | 70mm*70mm~200mm*200mm | 2.0mm-6.0mm | 30m-60m/min |

| For more customizations, please contact | |||||

description2

Company Introduction

At Mivi Machinery Company, we specialize in the manufacture of carbon steel pipe making machines. Our machines are designed to meet the unique needs of our clients, offering custom solutions to fit their specific requirements.

description2

Our Certificates

description2

Our Exhibition

description2

Pipe Making Machine Maintenance

1. Check the oil level gauge on the oil tank frequently, and the oil level shall not be lower than the specified value.

2. When the oil filter is blocked by dirt, it needs to be replaced in time; when the coarse oil filter is blocked, it should be cleaned in time, once every 3 months.

3. Fill the fuel tank with oil. It must be filtered, and the oil must not be mixed with impurities such as moisture, rust, metal shavings and fibers.

4. When starting the oil pump in winter or cold areas, it should be started and stopped, repeated several times to increase the oil temperature, and start working after the hydraulic pump station is running flexibly.

5. All knobs on the hydraulic pump station shall not be moved by non-operators.

6. Frequently observe whether the power supply voltage fluctuates abnormally, and check it every 3 months or so.

The correct maintenance of the pipe-making machine plays a very positive role in the efficiency and life of the equipment.

description2