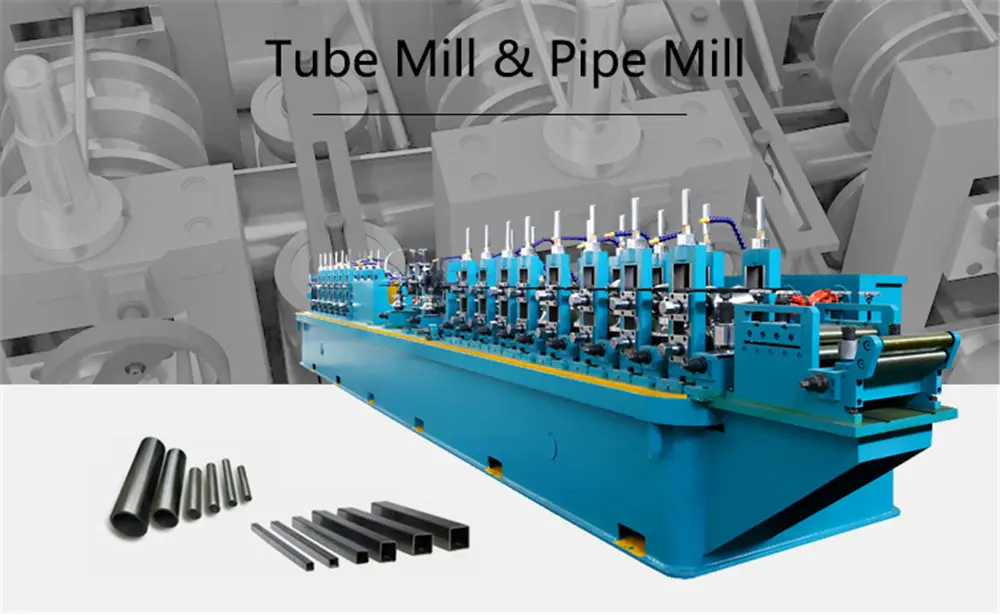

MG-219 Steel Pipe Manufacturing Machine Tube Mill Production Line

description2

Product Details

Our steel pipe machines are designed and developed with precision and efficiency in mind. We understand the importance of reliable and durable machines for pipe production, which is why we take great care in the development of our equipment. Our machines produce high quality pipes with consistent precision, making your production process seamless and efficient. With our expertise in the industry, we are able to provide customized solutions to meet your specific tube manufacturing needs, ensuring that you get the perfect machine to meet your production requirements.

We are committed to providing best-in-class tube manufacturing machines and we offer our products at factory prices, making them accessible to businesses of all sizes. We believe that high quality equipment should be affordable and we strive to make our machines as cost effective as possible. By importing our machines at factory prices, you can ensure that you get the best value for your investment. In addition, we provide comprehensive support for our machines, ensuring you get the knowledge and help you need to maximize the productivity and life of your equipment.

Whatever your pipe manufacturing needs, we can help. Whether you need a pipe machine, a square pipe machine, a round pipe machine or a custom solution, we have the expertise and resources to provide you with the perfect machine. Our commitment to excellence and customer satisfaction sets us apart in the industry and we are confident that our pipe making machines will exceed your expectations. Contact us today to learn more about our pipe manufacturing machines and take the first steps to increase your pipe production capacity.

Our steel pipe machine is mainly used in auto parts industry, pet cage accessories, kitchen hardware accessories, garden tools accessories and so on. Large screen, clear operation interface. Parameter setting is simple and easy to learn, can store multiple groups of programs. The length of the tailings is automatically converted by the system, which is simple and practical. The production line of the Chinese rectangular tube mill adopts multi-point bending combined forming technology to process the strip steel directly into square rectangular tubes.

We believe that our steel pipe machines can compete with any other similar products in terms of quality, performance and price. The head structure adopts all gear transmission, the output torque is large, and it is not easy to wear. The machine head and the motor are connected with synchronous belt, which is not easy to slip, and the power output is stable. When the cutting size is longer, it can be fed in place at one time, saving time and improving efficiency.

Our pipe factory has a variety of different steel pipe manufacturing machines with a coverage range from 7mm to 219mm and a thickness of 0.2mm to 7.0mm. Pipe production machine mainly produces galvanized pipe, carbon steel pipe. The pipe manufacturing machine can not only manufacture round pipe, square pipe, rectangular pipe, oval pipe and other special-shaped pipe. Finished pipes for decoration, such as furniture, handrails, household appliances, construction pipes.

description2

Machine Parameter

|

Item No.

|

MG-219

|

|

Outer Diameter

|

76.2mm-219.1mm

|

|

Wall Thickness

|

2.0mm-8.0mm

|

|

Square tube size

|

60x60mm~170x170mm

|

|

Square tube thickness

|

2.0mm~8.0mm

|

|

Production Speed

|

30-45m/min

|

|

Pipe length

|

4M~8M

|

|

Driving Motor

|

280KW*1 set

|

|

HF Welder Power

|

280KW

|

|

Weight

|

≤20000kg

|

|

Core Components

|

PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump

|

|

Warranty of core components

|

1 Year

|

|

Applicable Industries

|

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Retail, Construction works |

description2

Production Line

description2

Welded Pipe Making Machine

| Model | Outer diameter | Pipe thickness | Square tube size | Square tube thickness | Produce speed |

| MG-16 | 7mm-25mm | 0.3mm-1.0mm | 10mm*10mm-20mm*20mm | 0.3mm-0.8mm | 30m-100m/min |

| MG-25 | 8mm-32mm | 0.4mm-1.2mm | 10mm*10mm-25mm*25mm | 0.4mm-1.0mm | 30m-100m/min |

| MG-28 | 10mm-50.8mm | 0.5mm-1.8mm | 10mm*10mm-45mm*45mm | 0.6mm-1.5mm | 30m-100m/min |

| MG-32 | 13mm-50.8mm | 0.6mm-2.0mm | 10mm*10mm-40mm*40mm | 0.6mm-1.5mm | 30m-100m/min |

| MG-45 | 13mm~60mm | 0.6mm-2.5mm | 10mm*10mm~45mm*45mm | 0.6mm~2.0mm | 30m-100m/min |

| MG-50 | 19mm-76mm | 0.7mm-2.75mm | 15mm*15mm-60mm*60mm | 0.6mm-2.0mm | 30m-100m/min |

| MG-60 | 25mm-80mm | 1.0mm-3.25mm | 20mm*20mm-50mm*50mm | 0.8mm-3.0mm | 30m-80m/min |

| MG-76 | 30mm-90mm | 1.0mm-4.0mm | 50mm*50mm-130mm*130mm | 1.5mm-4.0mm | 15m-70m/min |

| MG-127 | 32mm-127mm | 1.5mm-4.0mm | 50mm*50mm-130mm*130mm | 1.5mm-4.0mm | 20m-70m/min |

| MG-140 | 32mm-140mm | 0.8mm~4.0mm | 25mm*25mm-110mm*110mm | 0.8mm-3.5mm | 30m-70m/min |

| MG-165 | 50mm-165mm | 2.0mm-5.0mm | 25mm*25mm-100mm*100mm | 1.0mm-4.0mm | 30m-50m/min |

| MG-172 | 89mm-172mm | 1.0mm~5.0mm | 70mm*70mm~130mm*130mm | 1.0mm-4.0mm | 30m-70m/min |

| MG-219 | 76.2mm-219.1mm | 2.0mm~8.0mm | 60mm*60mm~170mm*170mm | 2.0mm-8.0mm | 30m-45m/min |

| MG-254 | 89mm-254mm | 2.0mm~7.0mm | 70mm*70mm~200mm*200mm | 2.0mm-6.0mm | 30m-60m/min |

| For more customizations, please contact | |||||

description2

Company Introduction

At Mivi Machinery Company, we specialize in the manufacture of carbon steel pipe making machines. Our machines are designed to meet the unique needs of our clients, offering custom solutions to fit their specific requirements.

description2

Our Certificates

description2

Our Exhibition

description2

FAQ

Q: What products do you make?

A: Our products are mainly various types of pipe making machines. We have a lot of experience in this field.

Q: What are the advantages of your machines?

A: We have first-class suppliers. Support customization, worry-free after-sales.

Q: Can you put the company name or logo on the product?

A: Yes. We can print your logo or company name on the product by stamping or coating it

Q: How many workers do you need to operate this machine?

A: If the worker knows how to operate the machine, one worker can operate two machines at the same time.

Q: How long does it take to replace the roller on the machine?

A: If a worker changes the roller once, it takes about 3 hours, but sometimes it depends on whether the worker has it

Familiar enough to decide.

Q: How many tons does the average machine produce per month?

A: Our machines depend on the model. In this case, one machine can produce 70 tons per month.

Q: How do we get after-sales service for the machine?

A: We will provide installation, operation, maintenance and other aspects of technical support, you can also arrange technical engineers to the site

Your company.

description2