MG-165 Steel Pipe Mill Machine Industrial MS GI Tube Mill

description2

Product Details

One of the main advantages of our pipe making machines is their versatility. The machine is capable of producing both square and round tubes, providing manufacturers with unparalleled flexibility. This means you can streamline your production processes and easily meet a wide range of customer needs. In addition, the machine can handle a wide range of outside diameters and wall thicknesses, making it suitable for a variety of applications from construction to automotive manufacturing.

In addition, our steel tube manufacturing machines are designed for optimal efficiency. High production speeds from 30 m/min to 60 m/min ensure that you can meet deadlines and maximize production without compromising quality. This will ultimately increase the productivity of the business and save costs. In addition, the precise and consistent performance of the machines ensures the production of high-quality pipes that meet industry standards.

Last but not least, our pipe manufacturing machines are available at competitive factory prices, making them an attractive investment for manufacturers. With its advanced features and cost-effective price, this machine presents a significant opportunity for businesses to upgrade their production capabilities and stay ahead of the competition. As a leading supplier of industrial machinery, we are committed to providing quality equipment that enables our customers to achieve their production goals efficiently and cost-effectively.

Together, our new steel tube manufacturing machines stand out as industry game changers, offering manufacturers unmatched versatility, efficiency and value. Whether you need a square pipe making machine, a round pipe making machine, or a combination of both, this product can meet your precise and reliable production needs. Invest in our pipe manufacturing machines today and experience the transformative impact it can have on your manufacturing business.

description2

Machine Parameter

|

Item No.

|

MG-165

|

|

Outer Diameter

|

50mm-165mm

|

|

Wall Thickness

|

2.0mm-5.0mm

|

|

Square tube size

|

50×50mm~130×130mm

|

|

Square tube thickness

|

1.5mm~4.0mm

|

|

Production Speed

|

30-50m/min

|

|

Pipe length

|

4M~8M

|

|

Driving Motor

|

370KW*1 set

|

|

HF Welder Power

|

400KW

|

|

Weight

|

≤10000kg

|

|

Core Components

|

PLC, Engine, Bearing, Gearbox, Motor, Pressure vessel, Gear, Pump

|

|

Warranty of core components

|

1 Year

|

|

Applicable Industries

|

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Retail, Construction works |

description2

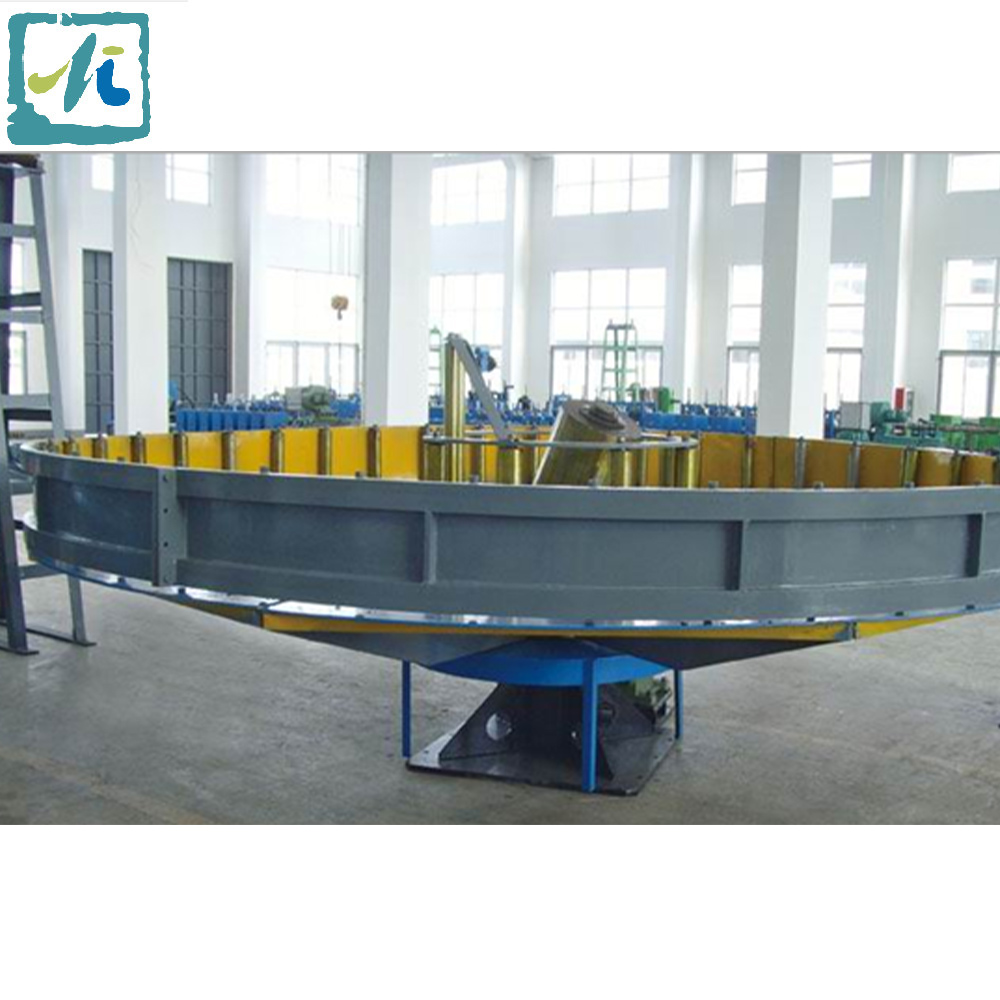

Production Line

description2

Welded Pipe Making Machine

| Model | Outer diameter | Pipe thickness | Square tube size | Square tube thickness | Produce speed |

| MG-16 | 7mm-25mm | 0.3mm-1.0mm | 10mm*10mm-20mm*20mm | 0.3mm-0.8mm | 30m-100m/min |

| MG-25 | 8mm-32mm | 0.4mm-1.2mm | 10mm*10mm-25mm*25mm | 0.4mm-1.0mm | 30m-100m/min |

| MG-28 | 10mm-50.8mm | 0.5mm-1.8mm | 10mm*10mm-45mm*45mm | 0.6mm-1.5mm | 30m-100m/min |

| MG-32 | 13mm-50.8mm | 0.6mm-2.0mm | 10mm*10mm-40mm*40mm | 0.6mm-1.5mm | 30m-100m/min |

| MG-45 | 13mm~60mm | 0.6mm-2.5mm | 10mm*10mm~45mm*45mm | 0.6mm~2.0mm | 30m-100m/min |

| MG-50 | 19mm-76mm | 0.7mm-2.75mm | 15mm*15mm-60mm*60mm | 0.6mm-2.0mm | 30m-100m/min |

| MG-60 | 25mm-80mm | 1.0mm-3.25mm | 20mm*20mm-50mm*50mm | 0.8mm-3.0mm | 30m-80m/min |

| MG-76 | 30mm-90mm | 1.0mm-4.0mm | 50mm*50mm-130mm*130mm | 1.5mm-4.0mm | 15m-70m/min |

| MG-127 | 32mm-127mm | 1.5mm-4.0mm | 50mm*50mm-130mm*130mm | 1.5mm-4.0mm | 20m-70m/min |

| MG-140 | 32mm-140mm | 0.8mm~4.0mm | 25mm*25mm-110mm*110mm | 0.8mm-3.5mm | 30m-70m/min |

| MG-165 | 50mm-165mm | 2.0mm-5.0mm | 25mm*25mm-100mm*100mm | 1.0mm-4.0mm | 30m-50m/min |

| MG-172 | 89mm-172mm | 1.0mm~5.0mm | 70mm*70mm~130mm*130mm | 1.0mm-4.0mm | 30m-70m/min |

| MG-219 | 76.2mm-219.1mm | 2.0mm~8.0mm | 60mm*60mm~170mm*170mm | 2.0mm-8.0mm | 30m-45m/min |

| MG-254 | 89mm-254mm | 2.0mm~7.0mm | 70mm*70mm~200mm*200mm | 2.0mm-6.0mm | 30m-60m/min |

| For more customizations, please contact | |||||

description2

Company Introduction

At Mivi Machinery Company, we specialize in the manufacture of carbon steel pipe making machines. Our machines are designed to meet the unique needs of our clients, offering custom solutions to fit their specific requirements.

description2

Our Certificates

description2

Our Exhibition

description2

FAQ

Q: What products do you make?

A: Our products are mainly various types of pipe making machines. We have a lot of experience in this field.

Q: What are the advantages of your machines?

A: We have first-class suppliers. Support customization, worry-free after-sales.

Q: Can you put the company name or logo on the product?

A: Yes. We can print your logo or company name on the product by stamping or coating it

Q: How many workers do you need to operate this machine?

A: If the worker knows how to operate the machine, one worker can operate two machines at the same time.

Q: How long does it take to replace the roller on the machine?

A: If a worker changes the roller once, it takes about 3 hours, but sometimes it depends on whether the worker has it

Familiar enough to decide.

Q: How many tons does the average machine produce per month?

A: Our machines depend on the model. In this case, one machine can produce 70 tons per month.

Q: How do we get after-sales service for the machine?

A: We will provide installation, operation, maintenance and other aspects of technical support, you can also arrange technical engineers to the site

Your company.

description2