0102030405

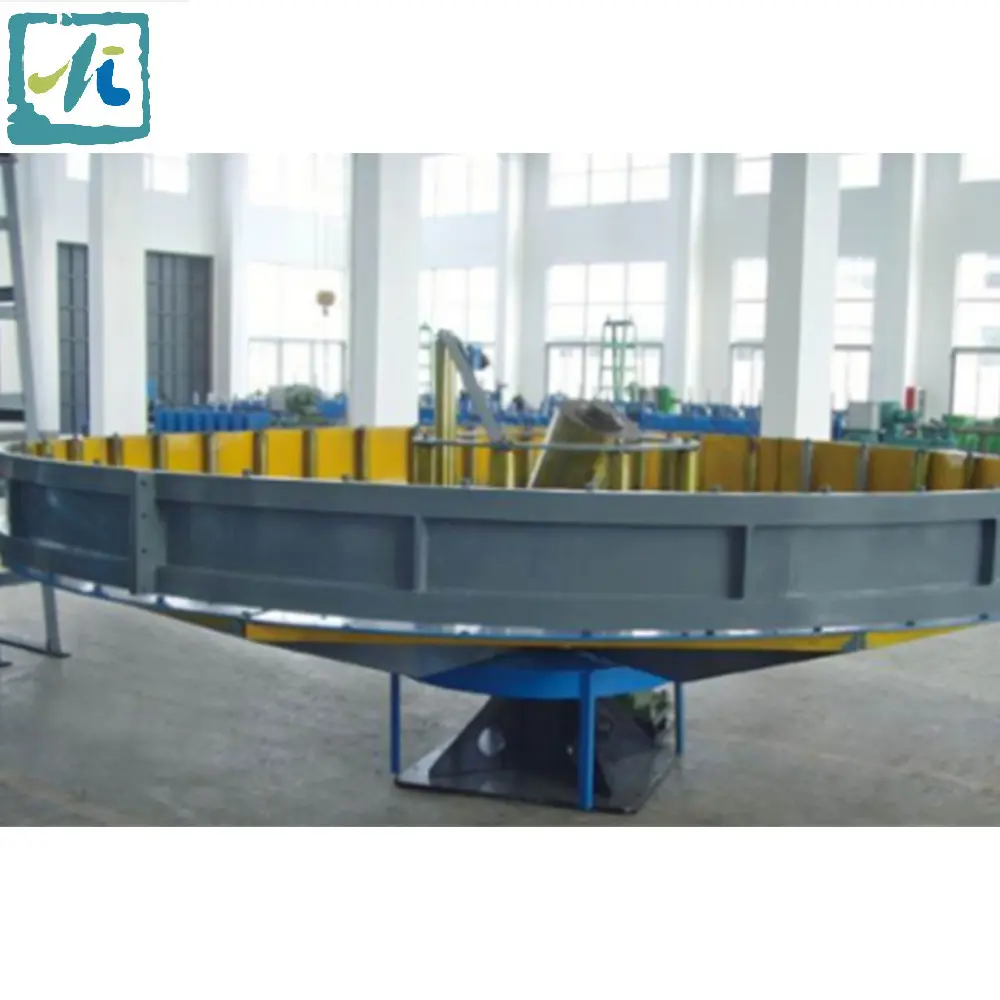

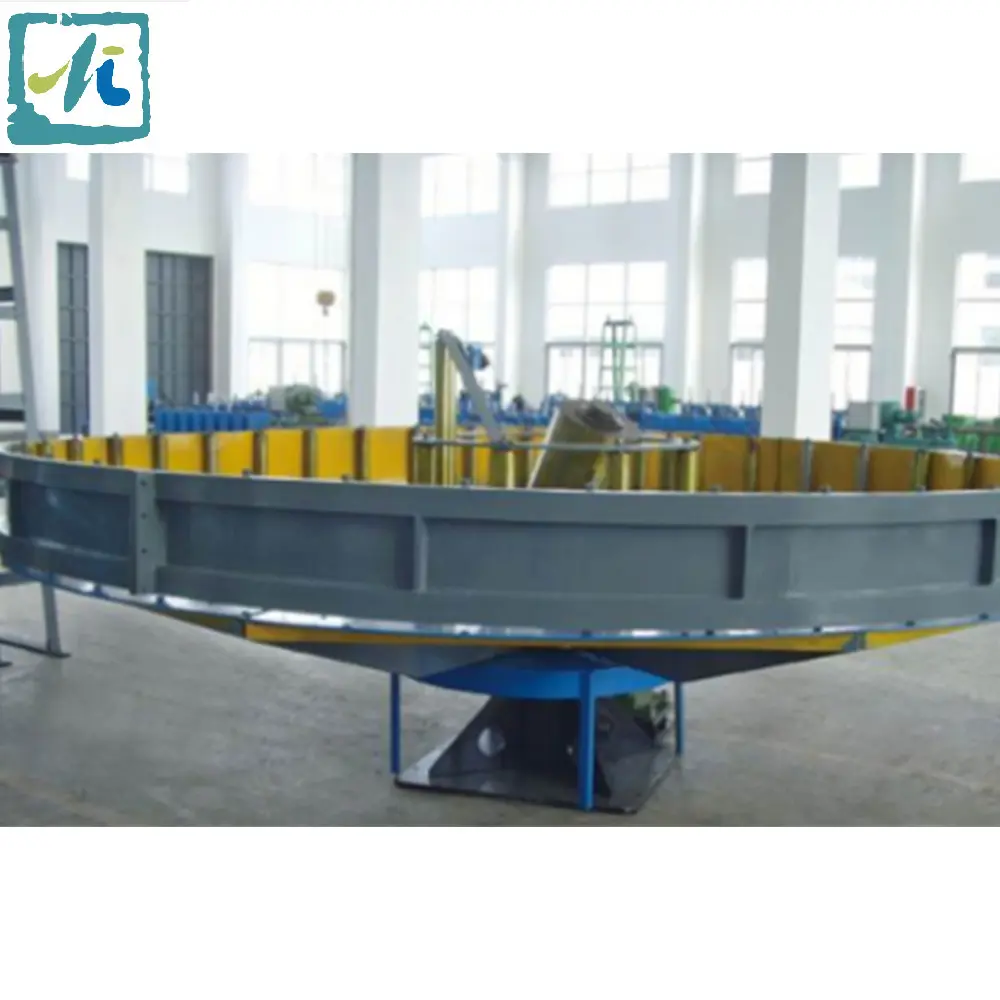

Horizontal accumulation Pipe Welding Machine Accessories

Product Details

| Accumulation diameter | 4.2~6.5m |

| Coil width | 40~800mm |

| Coil thickness | 0.6~7.0mm |

| Feeding speed | 70 ~200m/min |

| Feeding speed | 200m/min |

| Feeding motor | 18.5/37 kw AC motor |

| Main motor | 22/75 kw inverter motor |

| Accumulator volume | 120-1000m |

Horizontal accumulation, one of the equipment accessories of our high frequency pipe welding machine, is an indispensable part for pipe making machine. This innovative solution is designed to efficiently store a predetermined number of steel strips, ensuring supply to the host during the critical headend welding process. By integrating this system into your production line, you can significantly improve operational efficiency and maintain uninterrupted continuous production.

Horizontal accumulation plays a key role in the workflow of the optimized pipe making machine. By providing a reliable steel strip buffer, the main engine can operate at full capacity, minimizing downtime and maximizing production. This feature is especially useful in high-demand environments where consistent production is critical. The design of the system ensures that the steel strip is always available, enabling the host to perform welding tasks without frequent downtime to replenish materials.

Integrating Horizontal accumulation into your steel pipe manufacturing operations not only simplifies production, but also helps improve overall cost effectiveness. By reducing the frequency of machine downtime, you can achieve higher productivity levels and improve finished product quality. For manufacturers looking to increase their pipeline manufacturing capabilities, this accessory is an important investment to ensure your operations remain competitive in an ever-changing market. Experience the benefits of uninterrupted production with our Horizontal accumulation, the perfect complement to your pipe making machine.

description2

Machine Production Shows

description2

Welded Pipe Making Machine

| Model | Outer diameter | Pipe thickness | Square tube size | Square tube thickness | Produce speed |

| MG-16 | 7mm-25mm | 0.3mm-1.0mm | 10mm*10mm-20mm*20mm | 0.3mm-0.8mm | 30m-100m/min |

| MG-25 | 8mm-32mm | 0.4mm-1.2mm | 10mm*10mm-25mm*25mm | 0.4mm-1.0mm | 30m-100m/min |

| MG-28 | 10mm-50.8mm | 0.5mm-1.8mm | 10mm*10mm-45mm*45mm | 0.6mm-1.5mm | 30m-100m/min |

| MG-32 | 13mm-50.8mm | 0.6mm-2.0mm | 10mm*10mm-40mm*40mm | 0.6mm-1.5mm | 30m-100m/min |

| MG-45 | 13mm~60mm | 0.6mm-2.5mm | 10mm*10mm~45mm*45mm | 0.6mm~2.0mm | 30m-100m/min |

| MG-50 | 19mm-76mm | 0.7mm-2.75mm | 15mm*15mm-60mm*60mm | 0.6mm-2.0mm | 30m-100m/min |

| MG-60 | 25mm-80mm | 1.0mm-3.25mm | 20mm*20mm-50mm*50mm | 0.8mm-3.0mm | 30m-80m/min |

| MG-76 | 30mm-90mm | 1.0mm-4.0mm | 50mm*50mm-130mm*130mm | 1.5mm-4.0mm | 15m-70m/min |

| MG-127 | 32mm-127mm | 1.5mm-4.0mm | 50mm*50mm-130mm*130mm | 1.5mm-4.0mm | 20m-70m/min |

| MG-140 | 32mm-140mm | 0.8mm~4.0mm | 25mm*25mm-110mm*110mm | 0.8mm-3.5mm | 30m-70m/min |

| MG-165 | 50mm-165mm | 2.0mm-5.0mm | 25mm*25mm-100mm*100mm | 1.0mm-4.0mm | 30m-50m/min |

| MG-172 | 89mm-172mm | 1.0mm~5.0mm | 70mm*70mm~130mm*130mm | 1.0mm-4.0mm | 30m-70m/min |

| MG-219 | 76.2mm-219.1mm | 2.0mm~8.0mm | 60mm*60mm~170mm*170mm | 2.0mm-8.0mm | 30m-45m/min |

| MG-254 | 89mm-254mm | 2.0mm~7.0mm | 70mm*70mm~200mm*200mm | 2.0mm-6.0mm | 30m-60m/min |

| For more customizations, please contact | |||||

description2

Company Introduction

At Mivi Machinery Company, we specialize in the manufacture of carbon steel pipe making machines. Our machines are designed to meet the unique needs of our clients, offering custom solutions to fit their specific requirements.

description2

Our Certificates

description2

Our Exhibition

description2