CustomizedStraight Seam Welding Pipe Machine Production Line

description2

Product Details

Customized Straight Seam Welding Pipe Machine Production Line is a highly flexible and intelligent professional equipment designed for efficient production of high quality straight seam welding pipe machine. The production line can be fully customized according to customer needs, covering core parameters such as material thickness, pipe diameter range, welding process and production speed, and is widely used in construction and other manufacturing industries to meet the stringent requirements for precision welded pipes in diverse industries.

The core advantage of our product line is the custom design . Support personalized configuration, suitable for carbon steel, galvanized, stainless steel and other materials, the diameter range can be customized, the thickness range can be customized, to meet the strength and precision requirements of different scenarios.

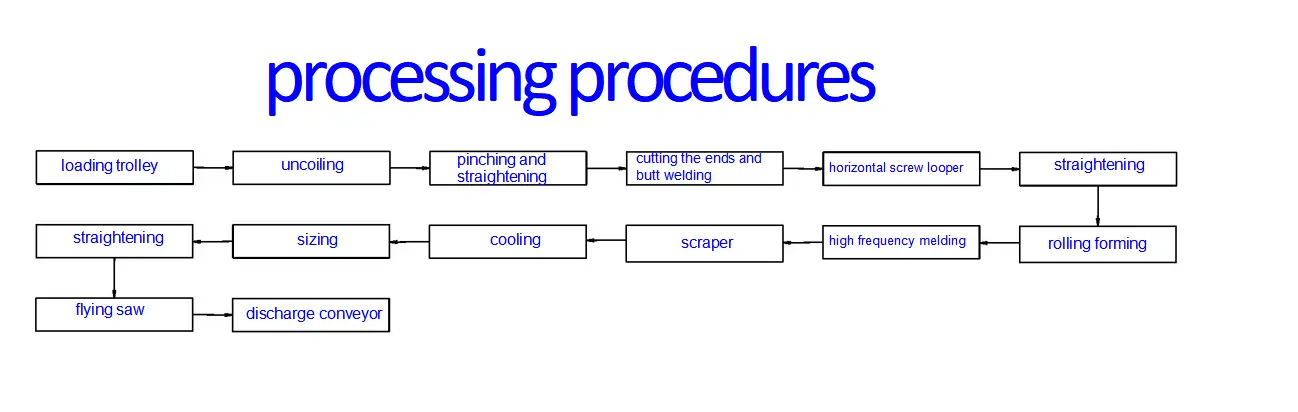

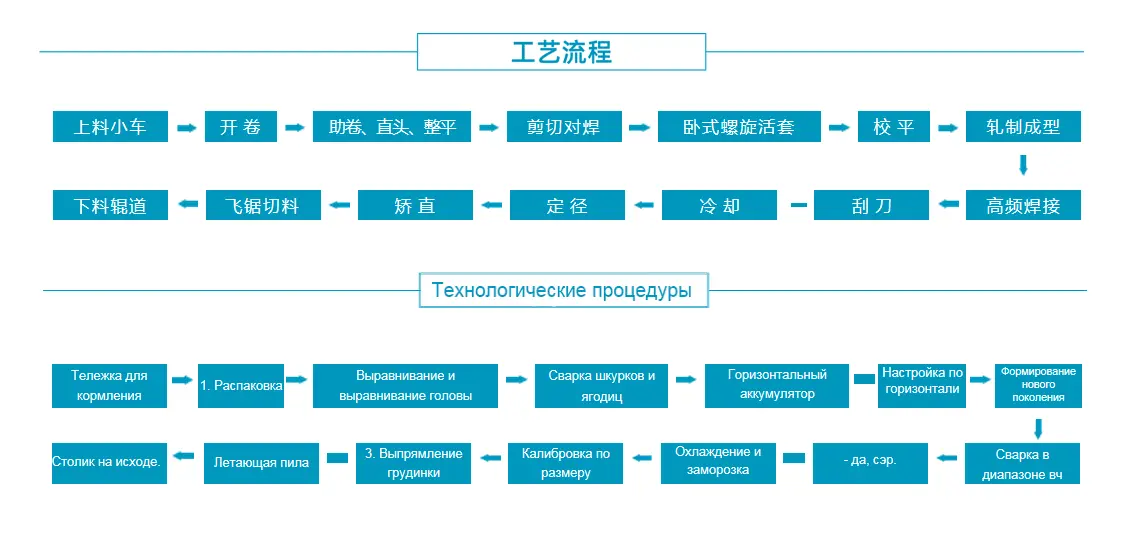

The core advantage of our production line is high efficiency and stable production . The automatic closed-loop control system, integrated PLC and high-precision servo drive, realizes the whole process automation from uncoiling, leveling, forming, welding, sizing to cutting, and the production speed can reach 30-120 m/min, greatly improving the production capacity. Modular structure design, easy to maintain and upgrade, key components (such as molding rolls, welding heads) use wear-resistant alloy material to ensure long service life and low failure rate of equipment.

The core advantage of our production line is energy saving and environmental protection . Optimize energy utilization, welding link adopts high-frequency inverter technology, energy consumption is reduced by 30%; Exhaust gas treatment system is optional to reduce production pollution and meet green manufacturing standards.

We support customized straight seam welding pipe production line typical configuration mainly:

Uncoiler : hydraulic expansion type or double cone head structure, support large tonnage coil efficient loading.

Leveler : multi-roll precision leveler to eliminate internal stress of materials.

Forming machine : progressive roll forming, suitable for complex cross section pipe.

Welding system : high-frequency induction welder/argon arc welder, equipped with automatic tracking and internal and external burring removal device.

Sizing machine : four rolls fine-tuning sizing to ensure the dimensional tolerance of ±0.1mm.

Flying saw cutting machine : servo drive, cutting accuracy ±0.5mm.

Stacking rack : automatic palletizing or online packaging, reducing manual intervention.

Our production line provides a one-stop solution covering equipment installation and commissioning, operational training, spare parts supply and lifelong technical support to ensure that customers quickly start production and continuously optimize production efficiency.

description2

Material Information

|

1 |

Applicable material |

Hot rolled strip steel, galvanized strip steel |

|

2 |

Material grade |

Low carbon steel/low alloy steel≤350Mpa |

|

3 |

Inner diameter of strip steel |

Φ508mm |

|

4 |

Outer diameter of strip steel |

≤Φ2200mm |

|

5 |

Weight of coil |

≤35tons |

description2

Finished Product Information

| 1 | Outer diameter of pipe | Φ219 ~Φ406mm |

| 2 | Thickness range of pipe | 4 .0~ 12 .7mm |

| 3 | Length of pipe | 4m--12m |

| 4 | Speed of production line | 40m/ min |

description2

Custom Rollers

description2

Tube Mill Making Machine

| Model | Outer diameter | Pipe thickness | Square tube size | Square tube thickness | Produce speed |

| MG-16 | 7mm-25mm | 0.3mm-1.0mm | 10mm*10mm-20mm*20mm | 0.3mm-0.8mm | 30m-100m/min |

| MG-25 | 8mm-32mm | 0.4mm-1.2mm | 10mm*10mm-25mm*25mm | 0.4mm-1.0mm | 30m-100m/min |

| MG-28 | 10mm-50.8mm | 0.5mm-1.8mm | 10mm*10mm-45mm*45mm | 0.6mm-1.5mm | 30m-100m/min |

| MG-32 | 13mm-50.8mm | 0.6mm-2.0mm | 10mm*10mm-40mm*40mm | 0.6mm-1.5mm | 30m-100m/min |

| MG-45 | 13mm~60mm | 0.6mm-2.5mm | 10mm*10mm~45mm*45mm | 0.6mm~2.0mm | 30m-100m/min |

| MG-50 | 19mm-76mm | 0.7mm-2.75mm | 15mm*15mm-60mm*60mm | 0.6mm-2.0mm | 30m-100m/min |

| MG-60 | 25mm-80mm | 1.0mm-3.25mm | 20mm*20mm-50mm*50mm | 0.8mm-3.0mm | 30m-80m/min |

| MG-76 | 30mm-90mm | 1.0mm-4.0mm | 50mm*50mm-130mm*130mm | 1.5mm-4.0mm | 15m-70m/min |

| MG-127 | 32mm-127mm | 1.5mm-4.0mm | 50mm*50mm-130mm*130mm | 1.5mm-4.0mm | 20m-70m/min |

| MG-140 | 32mm-140mm | 0.8mm~4.0mm | 25mm*25mm-110mm*110mm | 0.8mm-3.5mm | 30m-70m/min |

| MG-165 | 50mm-165mm | 2.0mm-5.0mm | 25mm*25mm-100mm*100mm | 1.0mm-4.0mm | 30m-50m/min |

| MG-172 | 89mm-172mm | 1.0mm~5.0mm | 70mm*70mm~130mm*130mm | 1.0mm-4.0mm | 30m-70m/min |

| MG-219 | 76.2mm-219.1mm | 2.0mm~8.0mm | 60mm*60mm~170mm*170mm | 2.0mm-8.0mm | 30m-45m/min |

| MG-254 | 89mm-254mm | 2.0mm~7.0mm | 70mm*70mm~200mm*200mm | 2.0mm-6.0mm | 30m-60m/min |

| For more customizations, please contact | |||||

description2

Company Introduction

At Mivi Machinery Company, we specialize in the manufacture of carbon steel pipe making machines. Our machines are designed to meet the unique needs of our clients, offering custom solutions to fit their specific requirements.

description2

Our Certificates

description2

Our Exhibition

description2

description2