Custom Steel Pipe Forming Machine Tube Mill

description2

Product Details

The machine that supports the customized and efficient production of steel pipes is our pipe welding machine. High-frequency pipe welding machine is one of the important equipment for the production of steel pipes, mainly used for the production of steel pipes. The working principle is to heat both ends of the steel pipe through the high frequency current, so that the steel pipe end face melt and form a molten pool, and then under the action of pressure to combine the two molten pools, so as to achieve the welding of the steel pipe. High-frequency pipe welding machine has the advantages of high production efficiency, good weld quality, easy operation, etc., and is widely used in construction, bridge, vehicle manufacturing and other fields.

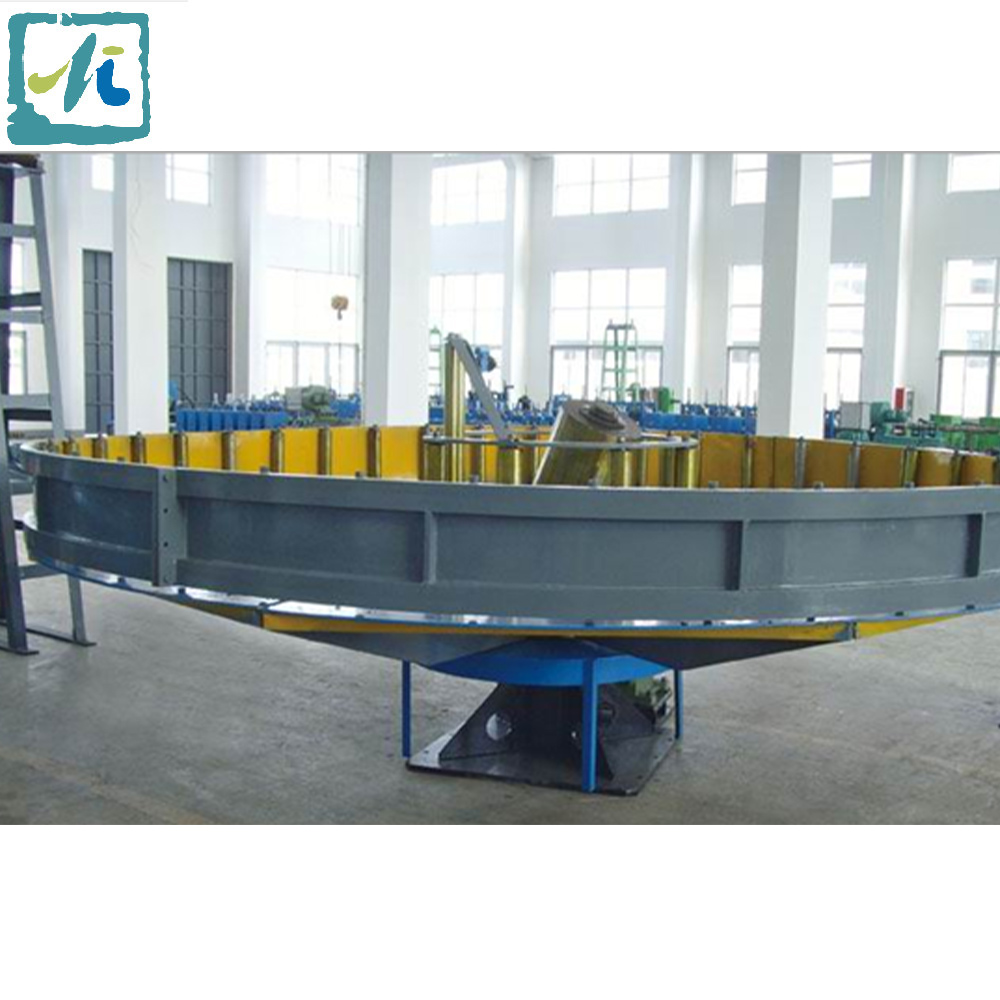

Our factory's pipe welding machines support customization, such as large diameter steel pipe manufacturing. The production of large diameter steel pipe, the working principle is to roll the steel plate into a tube, and then through welding to connect the steel plate together to form a steel pipe. This kind of pipe welding machine has the characteristics of large diameter, adjustable wall thickness and strong adaptability, and is suitable for pipeline construction in oil, natural gas, chemical industry and other industries.

Our pipe making machines use advanced technology to produce high quality steel pipes. Including feeding machine, tube rolling machine, sizing machine and other parts. The steel pipe machine unit processes the steel strip into steel pipe through the process steps such as welding and sizing. These steel pipes have the advantages of uniform wall thickness, high pressure and long service life.

description2

Custom Rollers

description2

Tube Mill Making Machine

| Model | Outer diameter | Pipe thickness | Square tube size | Square tube thickness | Produce speed |

| MG-16 | 7mm-25mm | 0.3mm-1.0mm | 10mm*10mm-20mm*20mm | 0.3mm-0.8mm | 30m-100m/min |

| MG-25 | 8mm-32mm | 0.4mm-1.2mm | 10mm*10mm-25mm*25mm | 0.4mm-1.0mm | 30m-100m/min |

| MG-28 | 10mm-50.8mm | 0.5mm-1.8mm | 10mm*10mm-45mm*45mm | 0.6mm-1.5mm | 30m-100m/min |

| MG-32 | 13mm-50.8mm | 0.6mm-2.0mm | 10mm*10mm-40mm*40mm | 0.6mm-1.5mm | 30m-100m/min |

| MG-45 | 13mm~60mm | 0.6mm-2.5mm | 10mm*10mm~45mm*45mm | 0.6mm~2.0mm | 30m-100m/min |

| MG-50 | 19mm-76mm | 0.7mm-2.75mm | 15mm*15mm-60mm*60mm | 0.6mm-2.0mm | 30m-100m/min |

| MG-60 | 25mm-80mm | 1.0mm-3.25mm | 20mm*20mm-50mm*50mm | 0.8mm-3.0mm | 30m-80m/min |

| MG-76 | 30mm-90mm | 1.0mm-4.0mm | 50mm*50mm-130mm*130mm | 1.5mm-4.0mm | 15m-70m/min |

| MG-127 | 32mm-127mm | 1.5mm-4.0mm | 50mm*50mm-130mm*130mm | 1.5mm-4.0mm | 20m-70m/min |

| MG-140 | 32mm-140mm | 0.8mm~4.0mm | 25mm*25mm-110mm*110mm | 0.8mm-3.5mm | 30m-70m/min |

| MG-165 | 50mm-165mm | 2.0mm-5.0mm | 25mm*25mm-100mm*100mm | 1.0mm-4.0mm | 30m-50m/min |

| MG-172 | 89mm-172mm | 1.0mm~5.0mm | 70mm*70mm~130mm*130mm | 1.0mm-4.0mm | 30m-70m/min |

| MG-219 | 76.2mm-219.1mm | 2.0mm~8.0mm | 60mm*60mm~170mm*170mm | 2.0mm-8.0mm | 30m-45m/min |

| MG-254 | 89mm-254mm | 2.0mm~7.0mm | 70mm*70mm~200mm*200mm | 2.0mm-6.0mm | 30m-60m/min |

| For more customizations, please contact | |||||

description2

Company Introduction

At Mivi Machinery Company, we specialize in the manufacture of carbon steel pipe making machines. Our machines are designed to meet the unique needs of our clients, offering custom solutions to fit their specific requirements.

description2

Our Certificates

description2

Our Exhibition

description2

description2