0102030405

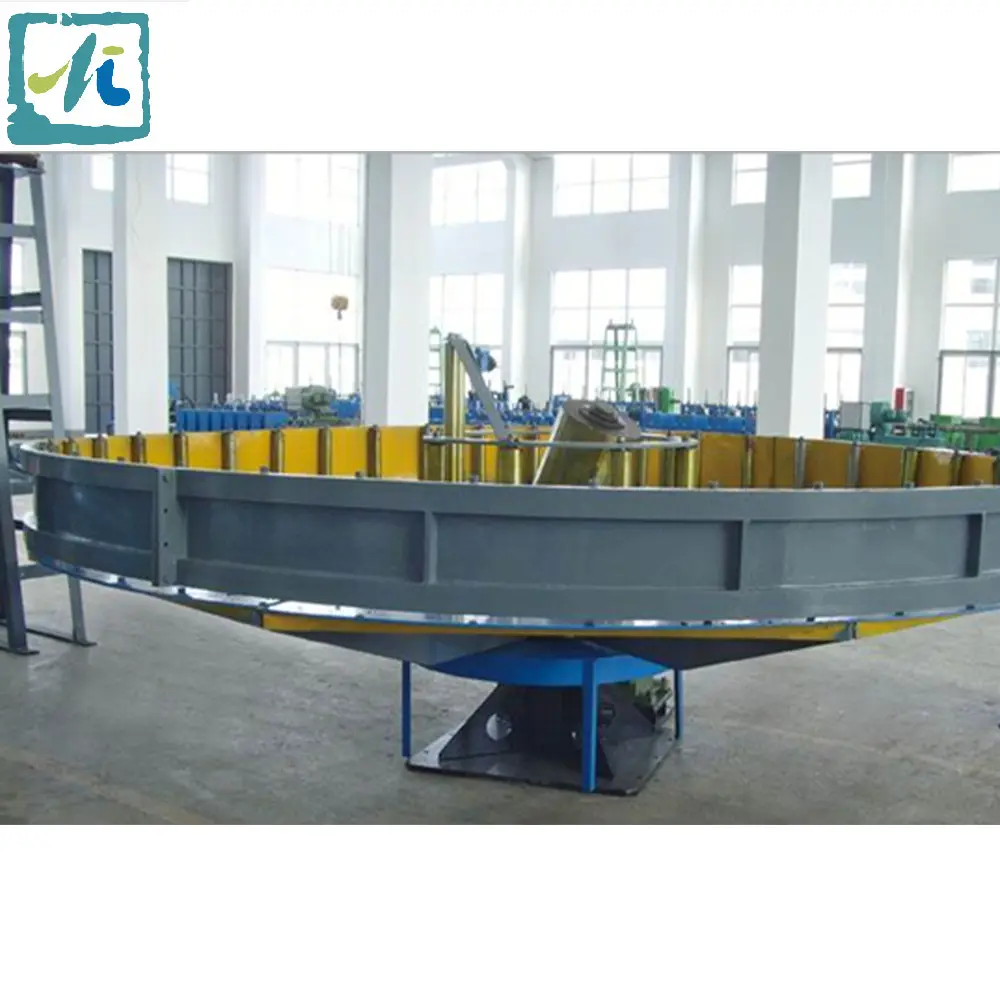

Custom MS GI Welded Tube Mill

The introduction of our most advanced high-frequency pipe welding equipment provides the ultimate solution for the production of high quality welded steel pipes. This advanced industrial equipment is designed to meet the requirements of modern manufacturing, providing precision, efficiency and reliability. The High frequency pipe welding unit is a comprehensive system that includes a series of carefully designed machines and tools for forming, welding and cutting steel strips into tubes of various sizes and shapes. With its cutting-edge technology and robust construction, the unit is ideal to meet the growing market demand for welded steel pipes.

The core of the high-frequency pipe welding unit is the high-frequency pipe welding machine, which is the key component to ensure the accurate welding of the steel strip. This machine is equipped with advanced features to provide consistent and high quality welds that meet stringent industry standards. In addition, the carbon steel pipe making machine included in the unit is designed to efficiently form the steel strip into the desired tube shape, thus providing versatility and flexibility in production. Because these important components work together, the unit provides a seamless and efficient production process, resulting in high-quality welded steel pipes.

The process begins by feeding steel strips into a series of rolls where they form the desired tube shape. The precision and accuracy of this forming process is essential to ensure the quality and integrity of the final product. A high-frequency welder then joins the edges of the formed steel strip to create a strong and durable weld. Finally, the cutting mechanism precisely cuts the welded pipe to the desired length, completing the production process in a precise and efficient manner.

In short, our high frequency welded pipe units are the epitome of excellence in welded steel pipe production. With its cutting-edge technology, precision engineering and seamless integration of basic components, the unit sets new standards for efficiency and quality in the industry. Whether it is large-scale manufacturing or specialized production needs, the unit is the final choice for welding steel pipe production to achieve excellent results.

Our Product

MIVI High-frequency Welding Pipe Making Machine Line

Item No. |

Outer diameter |

Wall thickness |

Production speed |

Driving motor |

HF welder power |

|---|---|---|---|---|---|

| MG-16 | 7mm-25mm | 0.3mm-1.0mm | 30-100m/min | 22kw*1set | 60kw |

| MG-25 | 8mm-32mm | 0.4mm-1.2mm | 30-100m/min | 45kw*1set | 60kw |

| MG-28 | 10mm-50.8mm | 0.5mm-1.8mm | 30-100m/min | 75kw*1set | 100kw |

Item No. |

Outer diameter |

Wall thickness |

Production speed |

Driving motor |

HF welder power |

|---|---|---|---|---|---|

| MG-32 | 13mm-50.8mm | 0.6mm-2.0mm | 30-100m/min | 90kw*1set | 100kw |

| MG-50 | 19mm-76mm | 0.7mm-2.75mm | 30-100m/min | 90kw*2set | 200kw |

| MG-60 | 25mm-80mm | 1.0mm-3.25mm | 30-80m/min | 90kw*2set | 200kw |

Item No. |

Outer diameter |

Wall thickness |

Production speed |

Driving motor |

HF welder power |

|---|---|---|---|---|---|

| MG-76 | 30mm-90mm | 1.0mm-4.0mm | 15-70m/min | 132kw*2set | 300kw |

| MG-127 | 32mm-127mm | 1.5mm-4.0mm | 20-70m/min | 160kw+200kw | 400kw |

| MG-165 | 50mm-165mm | 2.0mm-5.0mm | 30-50m/min | 200kw*2set | 500kw |

Item No. |

Outer diameter |

Wall thickness |

Production speed |

Driving motor |

HF welder power |

|---|---|---|---|---|---|

| MG-45 | 13mm-63.8mm | 0.6mm-2.0mm | 30-120m/min | 160kw*1set | 200kw |

| MG-140 | 32mm-140mm | 0.8mm-4.0mm | 30-70m/min | 320kw*1set | 300kw |

| MG-219 | 76mm-219mm | 2.0mm-8.0mm | 30-45m/min | 280kw*1set | 280kw |

Item No. |

Outer diameter |

Wall thickness |

Production speed |

Driving motor |

HF welder power |

|---|---|---|---|---|---|

| MG-254 | 89mm-254mm | 2.0mm-7.0mm | 30-60m/min | 400kw*1set | 500kw |

Our Advantages

1 Own CNC process center it can control quality of machine by ourself. Reduce invested cost for your project.

2 Rich experience engineer team and service team, with on line technology guidance and one to one service .

3 Supporting ONE STOP service, meet all requirement what you want ,Factory drawing can customized .

Our Factory

Yangzhou Mivi Machinery Manufacturing Co., Ltd. is a professional tube mill line manufacturer with over 20 years exporting experience.

Our main products: tube mill machines, cold rolling mills and relevant mechanical accessories.

We have exported to more than 20 countries and customzation service is avaliable for different requirements.

Now our factory have ISO9001, ISO14001certifications.

Welcome to inquiry us for more details. We will try our best to do win-win cooperation business.

Our Certificates

Our Exhibition

FAQ:

Q: What products do you make?

A: Our products are mainly various types of pipe making machines. We have a lot of experience in this field.

Q: What are the advantages of your machines?

A: We have first-class suppliers. Support customization, worry-free after-sales.

Q: Can you put the company name or logo on the product?

A: Yes. We can print your logo or company name on the product by stamping or coating it

Q: How many workers do you need to operate this machine?

A: If the worker knows how to operate the machine, one worker can operate two machines at the same time.

Q: How long does it take to replace the roller on the machine?

A: If a worker changes the roller once, it takes about 3 hours, but sometimes it depends on whether the worker has it

Familiar enough to decide.

Q: How many tons does the average machine produce per month?

A: Our machines depend on the model. In this case, one machine can produce 70 tons per month.

Q: How do we get after-sales service for the machine?

A: We will provide installation, operation, maintenance and other aspects of technical support, you can also arrange technical engineers to the site

Your company.