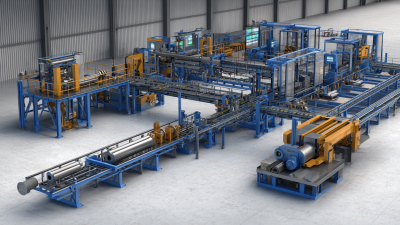

In the ever-evolving landscape of manufacturing, the Tube Mill Production Line stands at the forefront of innovation and efficiency. As we delve into 2023, it becomes crucial to explore the latest trends that are shaping the industry. From automation advancements to sustainable practices, these trends not only enhance productivity but also revolutionize the way tube mills operate. This article highlights the top five developments driving change within the Tube Mill Production Line, providing valuable insights for manufacturers aiming to stay competitive in a rapidly changing market.

As organizations strive to optimize their operations, understanding these trends is essential for strategically positioning their Tube Mill Production Line for success. The integration of cutting-edge technology and innovative techniques opens up new pathways for efficiency, ultimately leading to higher quality products and reduced operational costs. By examining these key trends, we can better appreciate the dynamic nature of tube mill production and the opportunities it presents for growth and sustainability in 2023 and beyond.

In 2023, the tube mill industry is witnessing a significant transformation driven by innovative automation technologies that enhance operational efficiency. One of the key advancements is the integration of AI and machine learning systems into production processes. These technologies enable real-time monitoring and predictive maintenance, minimizing downtime and optimizing resource utilization. By utilizing advanced algorithms, tube mills can analyze machine performance data, predict potential flaws, and implement timely interventions, resulting in a more streamlined production cycle.

Moreover, robotic automation is becoming increasingly prominent in tube mill operations. The deployment of collaborative robots (cobots) alongside human workers allows for safer and more efficient handling of materials. These systems can perform repetitive tasks with precision, freeing up skilled workers to focus on more complex aspects of production. Furthermore, automated quality inspection technologies, including vision systems and sensor-based solutions, ensure that the final products meet stringent quality standards while reducing labor costs and improving throughput. Overall, the adoption of these innovative technologies promises to redefine the landscape of tube mill production, making it more adaptable and efficient in a competitive market.

In 2023, sustainable manufacturing practices have become a focal point for tube production, as companies strive to minimize waste and reduce energy consumption. Manufacturers are adopting innovative technologies to streamline their operations, from advanced recycling techniques to energy-efficient machinery. These strategies not only contribute to a reduced carbon footprint but also enhance overall productivity by optimizing resource usage. The integration of recycled materials in the production process is increasingly common, allowing manufacturers to lessen their reliance on virgin resources while maintaining product quality.

Moreover, companies are investing in renewable energy sources to power their tube mills, thereby decreasing dependence on fossil fuels. By utilizing solar, wind, or bioenergy, manufacturers can significantly lower energy costs and enhance their sustainability profiles. Additionally, implementing real-time monitoring systems enables producers to identify inefficiencies and address them promptly, ensuring a continuous focus on reducing excess energy use and waste. These practices highlight a transformative shift within the tube manufacturing sector, where sustainability is not just a trend but a pivotal aspect of innovation and efficiency.

This chart illustrates the top trends in tube mill production lines for 2023, highlighting their impact on efficiency and sustainability.

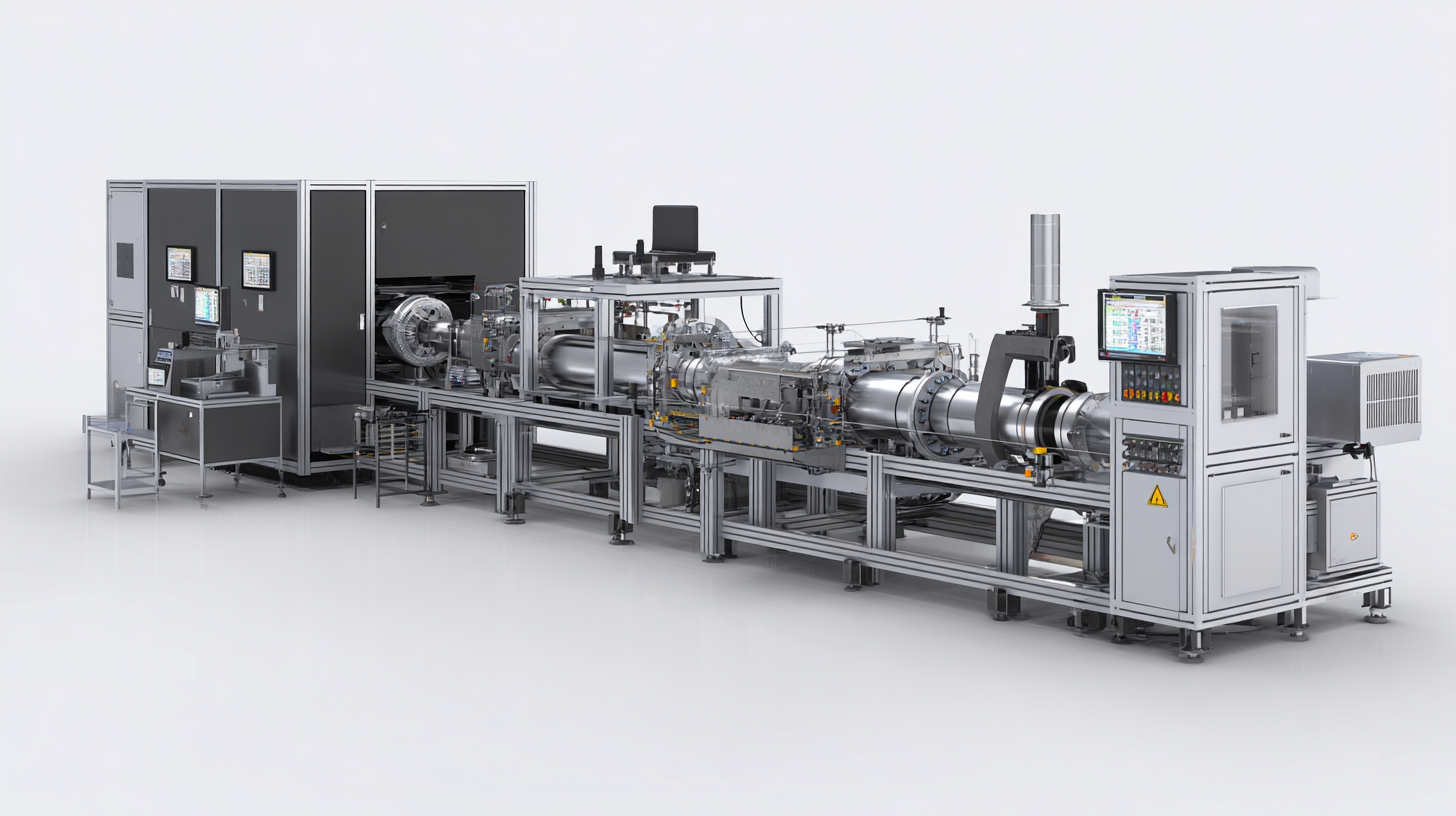

In 2023, the integration of Artificial Intelligence (AI) and the Internet of Things (IoT) is transforming tube mill production lines, particularly in the realm of enhanced quality control. According to a report by Markets and Markets, the AI in manufacturing market is set to grow from USD 1.41 billion in 2021 to USD 9.88 billion by 2026, demonstrating the urgent need for tube mills to adopt these technologies to remain competitive. Through real-time data analytics and predictive maintenance, AI can significantly reduce defects in production by identifying potential issues before they escalate, thus ensuring tighter control over the manufacturing process.

IoT devices are equally crucial in facilitating precision in tube mill output. These devices provide continuous monitoring of equipment and production parameters, allowing manufacturers to gather valuable insights into the operational process. The implementation of IoT in manufacturing can lead to an estimated reduction in operational costs by 20-30%, as cited in a study by McKinsey. By utilizing sensor data to optimize workflows and automate adjustments, tube mills can enhance their product quality while simultaneously increasing efficiency, ensuring that they meet the ever-growing demands of various industries. Such advancements not only improve productivity but also support sustainable practices by minimizing waste and resource consumption.

The integration of Industry 4.0 technologies is revolutionizing the tube mill production line, with data analytics at the forefront of this transformation. By harnessing vast amounts of data collected from various stages of the manufacturing process, companies can identify inefficiencies and optimize their operations. This real-time data analysis allows for predictive maintenance, minimizing downtime and enhancing productivity. Moreover, manufacturers can adjust parameters on-the-fly, ensuring that production processes remain agile and responsive to changes in demand.

Tips for maximizing the benefits of data analytics in tube mills include investing in advanced data collection tools and platforms that facilitate seamless information flow. Implementing machine learning algorithms can further refine the analysis, enabling more accurate forecasts and better decision-making. Additionally, fostering a data-driven culture within the workforce will empower employees to leverage insights for continuous improvement and innovation.

Collaboration between IT and production teams is crucial in unlocking the full potential of data analytics. By developing cross-functional teams, organizations can ensure that data-driven solutions are effectively integrated into everyday operations, leading to sustained improvements in performance and efficiency. Embracing this collaborative approach will pave the way for the future of tube mill production, ensuring companies remain competitive in an ever-evolving industry landscape.

| Trend | Description | Impact on Efficiency | Innovation Areas | Data Metrics Utilized |

|---|---|---|---|---|

| IoT Integration | Connecting machines for real-time monitoring. | Increased machine uptime. | Predictive maintenance. | Machine performance data. |

| AI-Powered Analytics | Using AI to analyze operational data. | Enhanced decision-making processes. | Quality control improvements. | Production yield metrics. |

| Automated Quality Checks | Implementing automation in quality assurance. | Reduction in defects. | Consistency in product quality. | Defect rates, compliance data. |

| Energy Efficiency Initiatives | Adopting energy-efficient technologies. | Lower operational costs. | Sustainability efforts. | Energy consumption metrics. |

| Advanced Robotics | Utilizing robots for production tasks. | Increased production speed. | Flexibility in operations. | Robot efficiency, output rates. |

| Augmented Reality (AR) for Training | Using AR in employee training programs. | Reduced training time. | Enhanced safety measures. | Training completion rates. |

| Flexible Manufacturing Systems | Systems that adapt to different products. | Increased adaptability. | Product variety management. | Production scheduling efficiency. |

| Blockchain for Supply Chain | Using blockchain for transparency. | Improved traceability. | Risk management in supply chains. | Transaction records, supply chain flow. |

| Customized Production Solutions | Tailoring production for individual clients. | Higher customer satisfaction. | Customer relationship management. | Customer feedback metrics. |

| Data-Driven Decision Making | Leveraging data for strategic decisions. | Enhanced operational efficiency. | Strategic planning. | Market analysis, operational KPIs. |

In 2023, predictive maintenance is emerging as a cornerstone for tube production lines, driving enhancements in uptime and operational efficiency. By leveraging advanced analytics and IoT technologies, manufacturers can proactively monitor equipment performance and predict potential failures before they occur. This shift towards a more data-driven approach not only minimizes downtime but also allows for more efficient scheduling of maintenance activities, ultimately leading to substantial cost savings.

The integration of predictive maintenance within Enterprise Asset Management (EAM) systems is further amplifying these benefits. As companies invest in digital tools to optimize asset effectiveness, they can achieve greater operational continuity. The continuous tracking of equipment conditions enables timely interventions, which are critical in high-demand environments. Looking ahead, the anticipated growth in related markets, such as automated laser cutting technology, highlights the broader trend towards automation and smart manufacturing processes, reaffirming predictive maintenance as a key driver of innovation in the tube mill production sector.