In the rapidly evolving landscape of modern manufacturing, the Tube Mill Production Line stands out as a transformative technology that redefines efficiency and productivity. According to a report by MarketsandMarkets, the global tube and pipe market is projected to reach $170 billion by 2025, with a substantial contribution from advancements in production lines. Companies are increasingly adopting automated tube mill production systems to enhance precision and reduce lead times, which has shown to increase overall manufacturing output by up to 30%. Additionally, the ability to customize products in real-time enables manufacturers to meet the dynamic demands of various industries, from construction to automotive. As we explore the seven ways the Tube Mill Production Line revolutionizes manufacturing practices, it becomes evident that this technology not only streamlines processes but also drives innovation, enabling businesses to compete effectively in a global market.

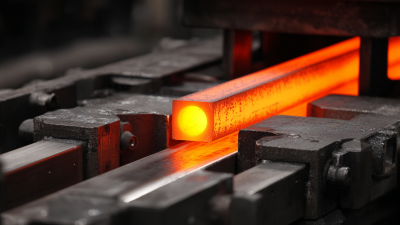

The introduction of Tube Mill Production Lines has dramatically transformed manufacturing efficiency, leading to a remarkable 30% increase in throughput. This enhancement is primarily attributed to advanced automation and streamlined processes that minimize manual intervention. Automated controls maintain precise specifications, enabling manufacturers to produce high-quality tubes at a faster pace. Additionally, real-time monitoring systems ensure that potential bottlenecks are swiftly addressed, further optimizing the overall production flow.

Moreover, Tube Mill Production Lines allow for greater flexibility in manufacturing various tube sizes and materials without significant downtime. This adaptability not only helps in meeting diverse customer demands but also reduces waste, making production more sustainable. The integration of modern technology, such as machine learning algorithms, aids in predictive maintenance, allowing for uninterrupted operation and reducing maintenance costs. As manufacturers continue to embrace these innovations, the impact on efficiency and productivity is undeniable, marking a significant shift in modern manufacturing practices.

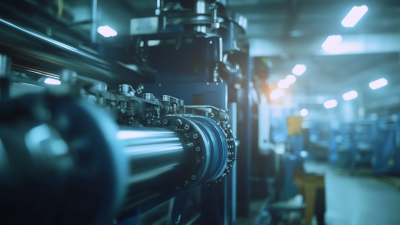

The integration of real-time analytics into the tube mill production line is reshaping modern manufacturing practices by enabling data-driven decision-making. By leveraging advanced analytics tools, manufacturers can monitor production processes in real time, identifying patterns, inefficiencies, and areas for improvement. This instantaneous access to data allows teams to make informed decisions that enhance production performance, reduce waste, and optimize resource allocation.

Furthermore, real-time analytics lead to proactive problem-solving rather than reactive measures. With data flowing continuously from the production floor, manufacturers can quickly address potential issues before they escalate into costly downtime or quality defects. This capability is crucial in maintaining competitive advantage in an industry where precision and efficiency are paramount. By adopting data-driven strategies, companies utilizing tube mill production lines are not only improving operational efficiency but also fostering a culture of continuous improvement and innovation.

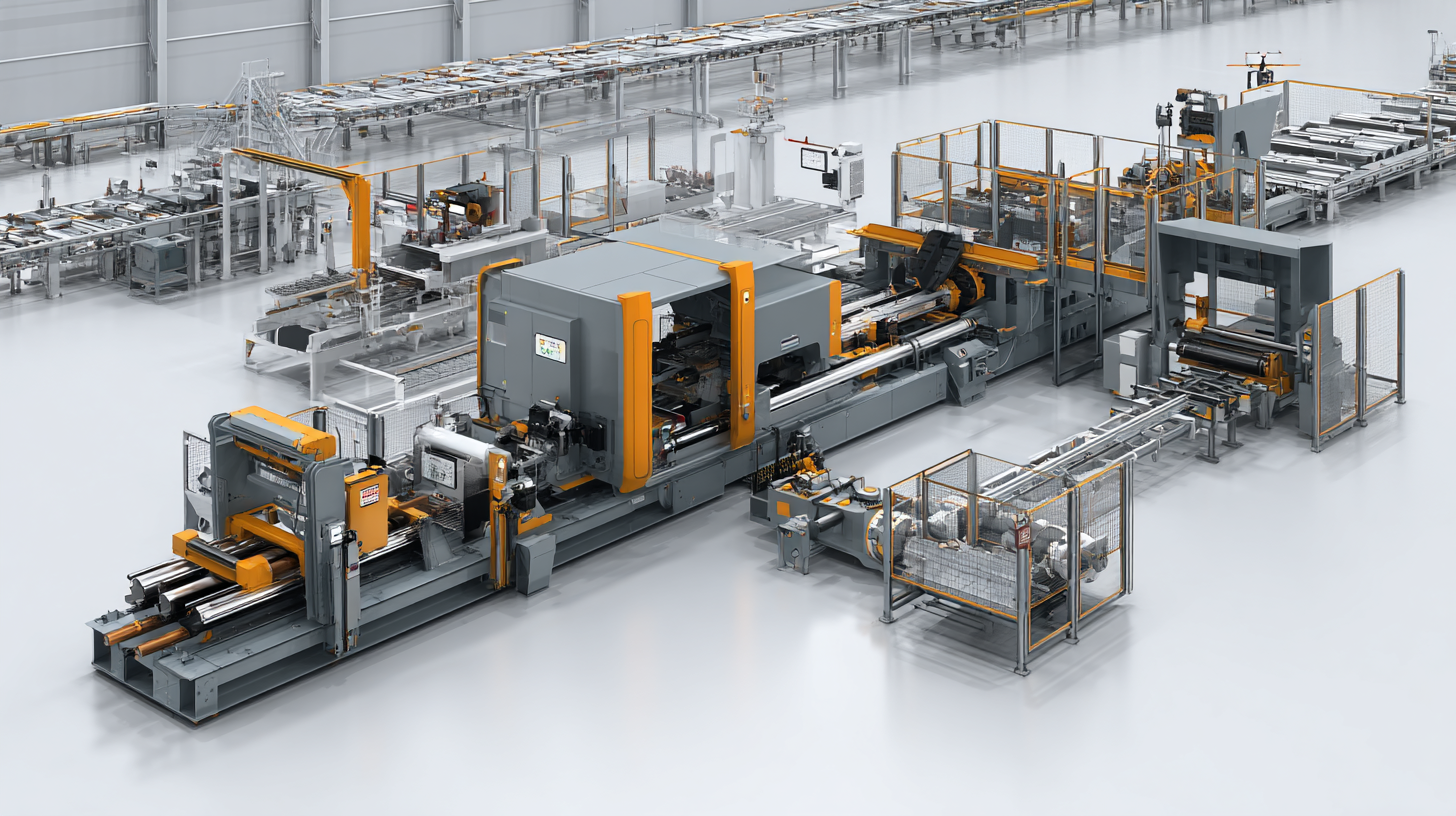

In the rapidly evolving landscape of modern manufacturing, tube mills stand out for their remarkable ability to deliver customization at scale. With flexible configurations, these production lines can adapt to a wide variety of market demands, thereby addressing the specific needs of diverse industries such as automotive, construction, and furniture. According to a report by the International Tube Association, the global market for tube and pipe production is expected to grow at a CAGR of 4.5% over the next five years, driven largely by the rising demand for tailored solutions.

Flexibility in tube mill configurations is a key differentiator. Manufacturers can modify parameters such as the diameter, thickness, and material of the tubes, allowing for rapid pivots in production without extensive downtime. This agility not only enhances efficiency but also reduces lead times, making it possible to meet customer requirements for bespoke products effectively. A recent study noted that companies leveraging customizable tube mills experienced a 20% increase in production efficiency.

Tip: To maximize the benefits of flexible tube mill configurations, manufacturers should invest in advanced software solutions that can forecast market trends and optimize production schedules. Additionally, training staff to adapt to new configurations can further streamline operations. Engaging in continuous research and development will ensure that you remain competitive in an ever-changing market landscape.

The adoption of tube mill production lines is a game changer for modern manufacturing, particularly in terms of sustainability. According to a report by the International Energy Agency, manufacturing accounts for 30% of global energy consumption, making the need for energy-efficient practices more crucial than ever. Tube mills, which are designed to optimize material usage and reduce waste, contribute significantly to lowering the carbon footprint of manufacturing processes. With advanced technologies enabling real-time monitoring and data analytics, manufacturers can achieve up to a 20% reduction in energy consumption while producing high-quality products.

**Tip:** Implementing predictive maintenance strategies can enhance the efficiency of tube mills. By analyzing equipment performance data, manufacturers can predict failures before they occur, minimizing downtime and energy waste.

Furthermore, innovative designs in tube mill production lines can lead to a significant reduction in scrap materials—often reporting savings of more than 15%. This translates into both financial savings and a reduced impact on landfills. By embracing these advancements, manufacturers not only meet regulatory requirements but also appeal to eco-conscious consumers looking for responsible production practices.

**Tip:** Consider collaborating with sustainability-focused suppliers who provide eco-friendly materials. This can amplify your sustainability efforts while also improving your product offerings in the marketplace.

| Sustainability Practice | Description | Impact on Waste Reduction (%) | Impact on Energy Consumption (%) | Implementation Cost ($) | Return on Investment (Years) |

|---|---|---|---|---|---|

| Improved Material Efficiency | Utilization of advanced materials to minimize waste during production. | 25 | 15 | 5000 | 2 |

| Energy Recovery Systems | Implementation of systems to recover and reuse energy within the production line. | 10 | 25 | 20000 | 3 |

| Automation and Smart Technology | Use of AI and automation to optimize processes and reduce human errors. | 20 | 30 | 15000 | 1.5 |

| Predictive Maintenance | Using data analysis to predict equipment failure and maintain machinery. | 5 | 10 | 10000 | 2 |

| Waste Management Systems | Systems that manage and recycle waste generated during production. | 30 | 20 | 8000 | 4 |

| Alternative Energy Sources | Integrating solar or wind energy into manufacturing operations. | 15 | 50 | 50000 | 5 |

| Sustainable Supply Chain Practices | Working with suppliers that prioritize sustainability. | 8 | 12 | 3000 | 1 |

Innovations in tube mill technology are significantly enhancing workforce safety in modern manufacturing practices. The integration of advanced automation and real-time monitoring systems in tube mills allows for more precise control over manufacturing processes, reducing the risk of human error. By implementing smart technology solutions, companies can ensure that operations remain within optimal safety parameters, allowing workers to focus on more strategic tasks rather than being solely responsible for routine monitoring.

Moreover, the advancements in tube mill design have introduced features such as safety guards, automatic shutdown protocols, and better ergonomic configurations. These improvements not only protect employees from potential hazards but also promote a safer working environment. As manufacturing continues to evolve, the emphasis on workforce safety is paramount, and tube mill technology is at the forefront of this revolution, enabling companies to meet the challenges of modern production while prioritizing the well-being of their workers.