The Tube Mill Production Line is an essential component in modern manufacturing. It primarily focuses on the production of tubular products used in various industries. This line utilizes advanced technology to create high-quality tubes with precise dimensions.

Moreover, the Tube Mill Production Line operates through several key stages. Initially, raw materials are fed into the system, and the milling process begins. Detailed care is taken at every step to ensure product quality. Yet, challenges may arise in managing material consistency and machine efficiency.

This production line plays a significant role in meeting market demands. Nevertheless, manufacturers must continuously assess the line’s performance. Regular evaluations can uncover areas for improvement. Adapting to new technologies and refining production processes is vital for success. Embracing change can lead to better outcomes in the Tube Mill Production Line.

A tube mill production line is a system designed for manufacturing tubular products. It primarily processes steel, yielding a variety of pipe and tube shapes. The production line typically includes several key components: strip steel, welding stations, and cutting equipment. According to industry reports, the global demand for steel pipes is projected to grow by 5% annually until 2025. This emphasizes the significance of tube mill operations.

In a standard tube mill setup, the strip steel is fed through rollers. These rollers shape the steel into a cylindrical form. Once formed, the edges of the steel strip meet and are welded together. This welding process is crucial, as it determines the quality of the final product. Quality control is essential; a small defect can lead to significant problems. Industry stats show that nearly 2% of production is often rejected due to such inconsistencies.

Energy consumption in tube mills also raises concerns. Reports indicate that tube mill operations consume a substantial amount of energy, making efficiency improvements vital. Enhancing energy efficiency not only reduces costs but also minimizes environmental impact. Companies face ongoing challenges in balancing these aspects within production workflows.

This bar chart illustrates the monthly production output of a typical tube mill production line over a six-month period. The data shows a steady increase in production, peaking in May.

The tube mill production line is a complex system designed to create pipes and tubes from various materials. Understanding its key components can help clarify how it operates. This production line typically consists of a few essential parts, including the decoiler, forming section, welding zone, and the cutting edge.

The decoiler unwinds the raw material, providing a continuous feed for the process. It's often an overlooked but crucial part. Next, in the forming section, the metal sheet is shaped into a cylinder using rollers. The machining needs precision here. After forming, the edge of the tube is welded together, usually employing specific techniques like high-frequency or laser welding. Each method has its advantages and challenges despite achieving strong joins.

Another important component is the sizing section. It ensures that the tubes meet desired specifications. However, not all tubes are perfect upon first attempt. Sometimes, the sizing process reveals inconsistencies. Operators need to be vigilant to avoid future issues. Finally, the cutting system trims the tubes to the required lengths. This step also demands accuracy and can lead to waste if not correctly executed. Each element in the tube mill production line plays a role that can impact overall efficiency and quality.

| Component | Function | Material Used | Typical Size | Production Speed (m/min) |

|---|---|---|---|---|

| Feeding System | Supplies raw material to the mill | Steel strip | Width: 1000mm | 5-15 |

| Forming Section | Shapes the flat strip into a tube | High carbon steel | Multiple roll stands | 5-20 |

| Welding Machine | Welds the edges of the tube | Copper, steel | N/A | 10-30 |

| Sizing Section | Finalizes the tube dimensions | Tool steel | Variable | 5-15 |

| Cutting Machine | Cuts tubes to required length | High-speed steel | N/A | 10-25 |

| Packing System | Prepares finished tubes for shipping | Cardboard, plastic | N/A | - |

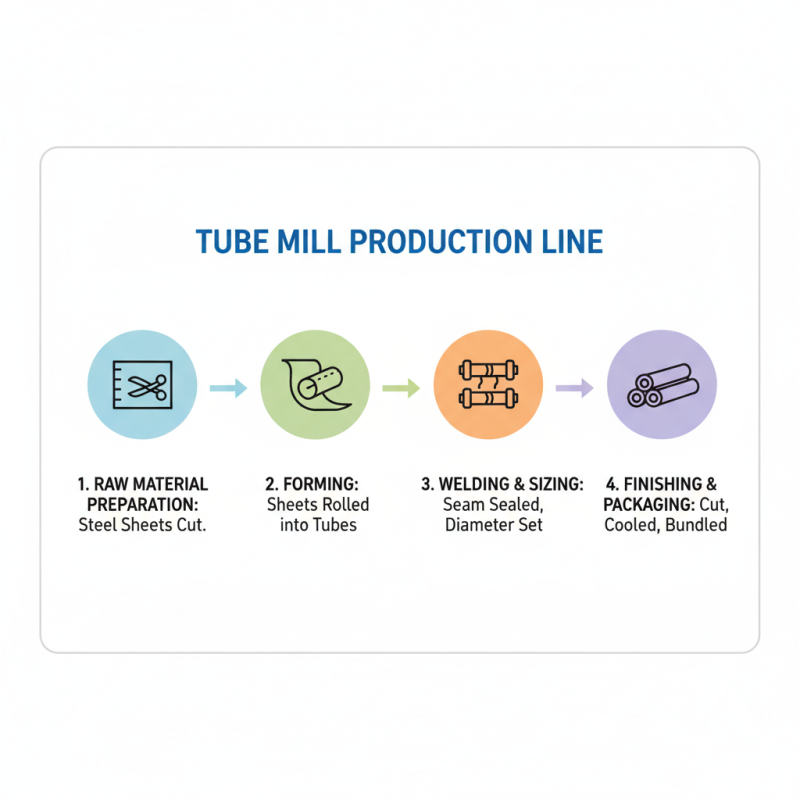

The Tube Mill Production Line involves a series of precise steps. It starts with raw material preparation. Steel sheets are cut into manageable sizes. Then, they undergo the forming process. This involves rolling the sheets into tubes.

Once formed, the tubes are welded. A high-frequency welding technique is commonly used here. This step requires careful alignment and timing. Imperfections in welding can lead to weaknesses in the final product. Quality control is essential at this stage.

During the shaping phase, the tubes are further processed. They may be resized or reshaped. This is crucial for ensuring they meet specifications. Additionally, proper inspection helps catch defects early.

**Tips:** Always monitor the temperature and speed during processing. Small adjustments can prevent major issues later. Regular training for operators can enhance efficiency and reduce errors.

Tube mill production lines have gained popularity in various sectors. They are known for their efficiency and versatility. According to industry reports, these lines can produce up to 80% more output than traditional methods. This increased efficiency can significantly lower production costs. In a competitive market, cost savings can make a significant difference.

Using a tube mill production line also offers adaptability. Manufacturers can switch between various product types quickly. This flexibility is key in meeting changing market demands. A report by Industry Insights noted that 70% of manufacturers find adaptability essential. Furthermore, the energy consumption of modern tube mills has decreased by nearly 30% in recent years. This is not only better for profit margins but also for the environment.

However, not all companies have successfully integrated tube mill production lines. Some struggle with the initial investment costs. Training staff can also prove challenging. Some users report a learning curve that can slow down initial production. These are important factors to consider when shifting to a tube mill production line.

Tube mills are essential in various industries for producing welded or seamless tubes and pipes. These mills operate by forming metal strips into tubes and welding them. Their flexibility makes them ideal for many applications, from construction to automotive manufacturing.

In construction, tube mills produce scaffolding and structural pipes. They replace traditional materials with lightweight, durable metal. The result is stronger structures that withstand various weather conditions. The automotive industry also benefits greatly. Tube mills create chassis components and exhaust systems, ensuring strength and flexibility. This versatility allows manufacturers to innovate continuously.

Tip: For industries switching to tube production, consider the material’s properties. Steel or aluminum can affect longevity and performance.

In the energy sector, tube mills are vital for creating components in winds turbines and pipelines. This demand highlights their adaptability. However, transitioning to tube mill production can pose challenges. Understanding equipment and process requirements is crucial to efficiency and quality assurance.

Tip: Regular training for staff can address skills gaps. Investing in employees improves production consistency.