In the rapidly evolving landscape of manufacturing, the integration of advanced technology into production lines has become imperative for success. High Frequency Welded Steel Pipe Making Machinery stands at the forefront of this transformation, offering enhanced efficiency and precision. According to a recent market analysis by Grand View Research, the global steel pipe market is projected to reach USD 142.57 billion by 2025, driven by increasing demand from various industries, including construction and oil and gas. Furthermore, with a reported annual growth rate of 6.1% in the steel pipe sector, the need for innovative and reliable production machinery has never been greater. By adopting high frequency welded steel pipe making machinery, manufacturers can not only optimize their production processes but also significantly reduce labor costs and material waste, making it an invaluable asset for the future of steel pipe manufacturing.

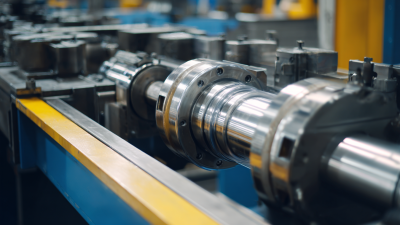

High frequency welding technology has revolutionized the manufacturing of steel pipes, providing significant advantages in speed and efficiency. This method entails the use of high-frequency electrical currents to generate heat in the edges of steel sheets, allowing them to fuse together without the need for additional filler materials. By utilizing electromagnetic fields, high frequency welding enables the seamless joining of metal, producing smooth and strong seams that greatly enhance the integrity of the finished product.

The benefits of high frequency welding extend beyond just the joining process. It allows for thinner wall structures, which can result in reduced raw material usage and lighter end products without compromising strength. Additionally, the rapid cycle times associated with this technology lead to higher throughput, making it an ideal choice for modern production lines aimed at meeting increasing market demand. As manufacturers continue to embrace this innovative approach, the future of steel pipe production looks promising, with a strong emphasis on efficiency, sustainability, and quality.

High frequency welded steel pipe making machinery is revolutionizing the manufacturing process with its numerous advantages. One of the standout benefits is its efficiency. The high-frequency welding technique significantly reduces processing time, allowing manufacturers to produce steel pipes at a much faster rate compared to traditional methods. This rapid production capability not only helps in meeting increasing market demands but also enhances overall productivity.

Another key advantage lies in the quality of the finished product. High frequency welding creates a strong and uniform bond without compromising the integrity of the steel. This leads to pipes that possess better mechanical properties and durability, making them suitable for various applications, from construction to automotive industries. Furthermore, the precision of this technology minimizes waste, contributing to more sustainable manufacturing practices and cost savings for businesses.

The alignment of efficiency, quality, and sustainability positions high frequency welded steel pipe making machinery as an essential tool for future production lines.

An efficient production line setup is crucial for the future of high-frequency welded steel pipe making machinery. Essential components such as automated robotic systems, digital platforms for monitoring and optimization, and flexible manufacturing layouts play a significant role in enhancing productivity and reducing costs. The integration of advanced technologies, including artificial intelligence and robotics, can streamline processes and minimize waste, ensuring that manufacturers remain competitive in a rapidly evolving market.

Furthermore, optimizing the assembly process through methodologies like non-dominated sorting genetic algorithms can lead to significant cost efficiencies. This approach allows manufacturers to balance their assembly lines more effectively, addressing issues from design to application. By focusing on continuous improvement and adopting next-generation line layouts, manufacturers can not only meet current demands but also prepare for future challenges, ultimately driving innovation and growth in this vital industry segment.

Optimizing your welding processes is crucial for enhancing efficiency and ensuring high-quality output in the making of high frequency welded steel pipes. As reported by the International Journal of Advanced Manufacturing Technology, implementing advanced automation in welding can boost production speed by 50% while also reducing defect rates by up to 30%.

To remain competitive, manufacturers must adopt modern techniques and machinery that facilitate quick setup changes and flexible production runs.

Tips: Regularly train your staff on the latest welding technologies and best practices to minimize errors and downtime. Furthermore, integrating real-time monitoring systems can provide valuable data, allowing for immediate adjustments to welding parameters when necessary.

The steel pipe manufacturing industry is on the brink of transformation, driven by innovations and shifting market demands. According to industry analyses, the steel pipe market is anticipated to grow significantly, with projections indicating an expansion from 2025 to 2033 across various applications, including seamless and welded pipes. This growth is propelled by heightened requirements in sectors such as oil and gas, chemical and petrochemical industries, automotive transport, and construction, reflecting a broader trend towards more sustainable practices.

As the world grapples with climate change, the adoption of cleaner energy solutions is becoming a universal priority. Experts at recent forums have emphasized the importance of advancing technologies that facilitate the production of high-quality, high-frequency welded steel pipes that can support renewable energy applications. The innovations discussed at the recent Chinese International Steel Pipe Summit highlight the synergies between health, sustainability, and technological advancement in the industry. By focusing on high-frequency welding techniques, manufacturers can not only enhance production efficiency but also align with global trends toward environmentally conscious manufacturing practices, ultimately paving the way for a more robust and future-ready steel pipe market.