Choosing the right Ms Pipe Making Machine Manufacturers is crucial for businesses in the manufacturing sector. With the global market for pipe making machinery projected to reach $5 billion by 2025, selecting a reliable manufacturer can significantly impact operational efficiency. Industry expert John Smith notes, "Quality machines lead to better production outcomes." This reiterates the need for careful selection in a competitive market.

Investing in an Ms pipe making machine involves meticulous consideration. Manufacturers vary in technology, cost, and service support. By analyzing technical specifications and user reviews, businesses can streamline their decision-making process. Reports indicate that 40% of machinery failures are linked to poor quality. Thus, companies should not compromise on quality.

Moreover, it’s essential to reflect on specific needs. The complexity of machinery should match production goals. Businesses must assess if a manufacturer aligns with their production capacities and long-term objectives. Even seasoned companies sometimes overlook these details, potentially affecting productivity. Prioritizing quality in Ms Pipe Making Machine Manufacturers cannot be overstated for sustainable growth.

When selecting a machine manufacturer, quality is crucial. The right manufacturer will provide reliable machines that enhance production. Poor choices can lead to operational issues. Delays and breakdowns cost time and money. A manufacturer’s reputation often reflects their commitment to quality. Researching their history can reveal much about their practices.

Support is another vital aspect. A reliable manufacturer should offer excellent customer service. Quick responses to inquiries can make a difference. However, not all manufacturers prioritize this. Some may be unresponsive after a sale, leading to frustration. It's essential to evaluate their support in advance.

Consider the technology they use. Advanced manufacturing techniques ensure efficiency and durability. However, some manufacturers may lag behind in innovation. This can impact production cycles negatively. Verify whether they regularly update their machines. Choosing the right manufacturer requires a comprehensive review of these factors. Engaging deeply with potential manufacturers can uncover shortcomings and strengths.

| Tip Number | Tips | Importance | Considerations |

|---|---|---|---|

| 1 | Research Manufacturer Experience | Experience ensures quality and reliability | Years in business, customer feedback |

| 2 | Evaluate Machine Quality | Avoiding defective products is crucial | Material used, technology employed |

| 3 | Check Customer Support | Reliable support is essential for maintenance | Response time, available channels |

| 4 | Compare Pricing | Understand market value to avoid overpaying | Quotations from different manufacturers |

| 5 | Inspect Certifications | Certifications verify compliance and safety | ISO, CE, or industry-specific standards |

| 6 | Ask for Product Demos | Demos show real performance of machines | Availability and setup for demonstrations |

| 7 | Review User Testimonials | Testimonials can provide insights on experience | Sources for reviews, user forums |

| 8 | Inquire about Warranty | Warranties protect against manufacturing defects | Length and terms of warranty provided |

| 9 | Understand Production Capacity | Match machine capacity with production needs | Output rate and machine efficiency |

| 10 | Evaluate After-sales Service | Good service ensures longevity of the machine | Support availability, parts supply |

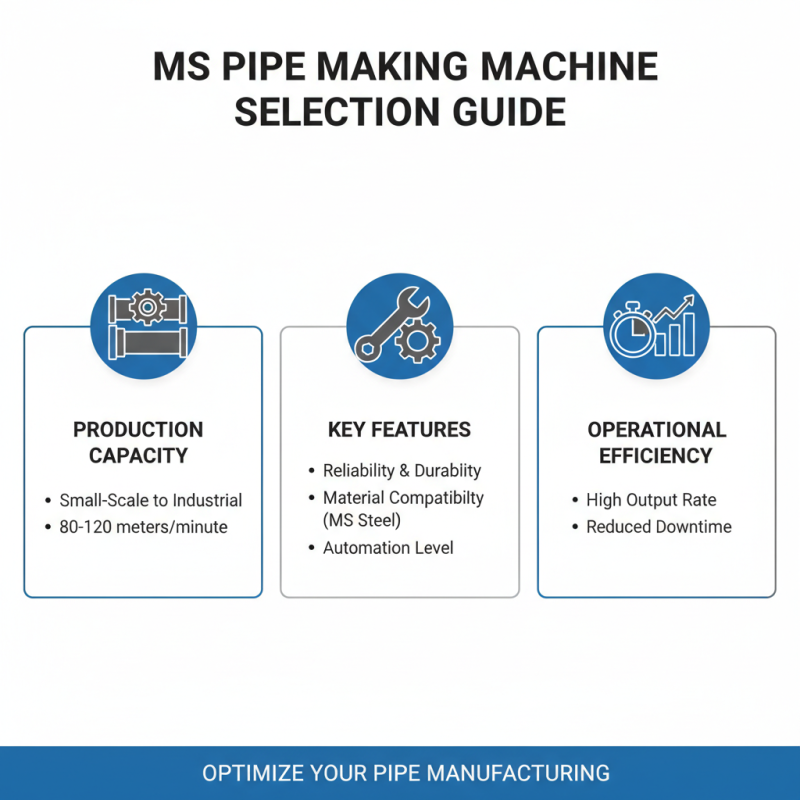

When selecting an MS pipe making machine, understanding key features is crucial. Consider the production capacity. Manufacturers often provide models that cater to different volumes, ranging from small-scale to industrial-level outputs. A reliable machine can produce pipes at a rate of 80 to 120 meters per minute. This is an important specification that can affect operational efficiency.

Examine the materials used in construction. High-quality steel should be the main component. Steel thickness influences durability. Machines with too thin parts can fail prematurely. This could lead to higher maintenance costs. Another feature to consider is automation. Advanced machines have programmable settings. This can improve consistency in production.

Tip: Always check the warranty. A strong warranty indicates the manufacturer's confidence in their product. This can also save costs in case of faults. Ask for a demo if possible. Real-time performance can reveal how a machine operates under pressure.

Keep in mind, not every manufacturer possesses extensive experience. Research thoroughly. Some might claim high efficiencies but deliver poorly. Analyze user reviews. Seek insights from other businesses in your industry. Asking questions can uncover limitations or strengths that are not immediately visible.

When selecting a manufacturer for Ms pipe making machines, reputation matters greatly. Start by researching industry experience. A manufacturer with years of practice usually understands market needs. They tend to produce reliable machines. Look for reviews and testimonials. Satisfied clients often share their experiences online.

Check for certifications and industry standards. A reputable manufacturer doesn't shy away from showcasing these credentials. These certifications can indicate quality. However, don’t just take their word for it. Contact existing customers to gather insights. Sometimes, the feedback can reveal flaws that aren't visible at first glance. Take note of any recurring issues.

Consider the communication style as well. A good manufacturer responds quickly to inquiries. They provide clear answers to your questions. If they leave you hanging, it could signal poor support later. Trust your instincts. Sometimes, a gut feeling can highlight potential issues. Reflect on your interactions and make informed choices.

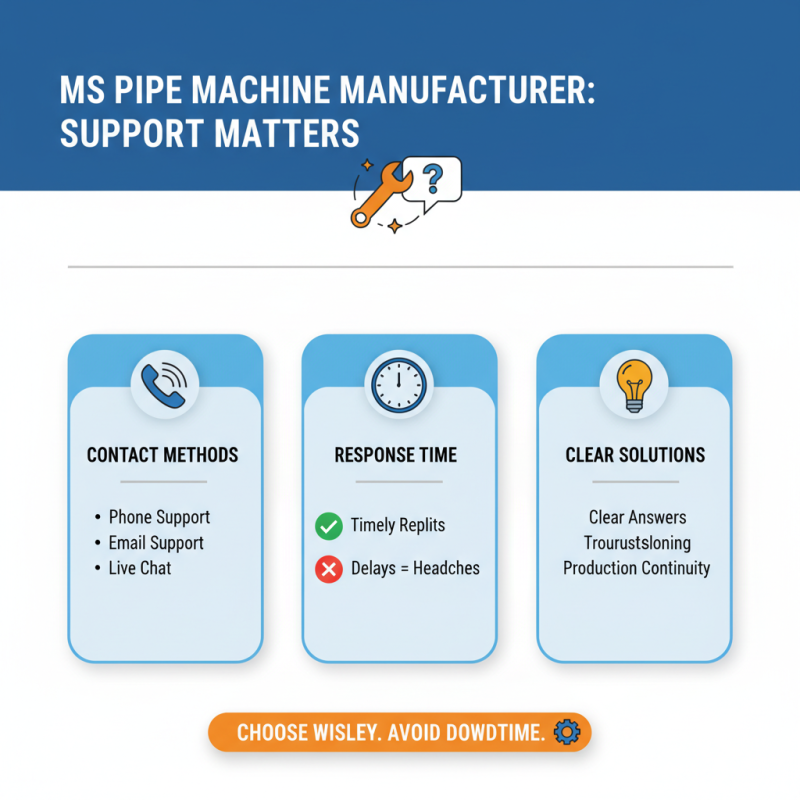

When selecting a manufacturer for Ms pipe making machines, evaluating customer support is crucial. A strong support system can make or break your production line. Manufacturers should offer various contact methods, like phone, email, and live chat. Check if they provide timely responses and clear answers. Doing so can avoid future headaches.

After-sales service is equally important. Good manufacturers will offer maintenance and spare parts support. Extended warranties or service packages can indicate a company's commitment to its products. It's worth investigating what other customers say about their experiences. Look for reviews that mention support responsiveness. Some companies may excel in machine quality but falter in customer care.

Consider the level of training provided for operators. Some manufacturers may claim their machines are easy to use. However, without proper training, this can be misleading. Investing in competent training can reduce misuse and enhance productivity. Assessing these factors can guide your decision-making. A machine is only as good as the support behind it.

When selecting Ms pipe making machine manufacturers, comparing pricing is crucial. Different manufacturers offer varying prices depending on quality and features. It's essential to gather quotes from multiple sources. Don't just focus on the initial cost; consider the overall value. The cheapest option may lead to higher maintenance costs down the line. You should also evaluate what is included in the price. Some manufacturers may offer additional tools or services that could be beneficial.

Warranty offers are equally important. A good warranty indicates the manufacturer's confidence in their product. Look for warranties that cover crucial components for an extended period. Short warranties might signal potential issues. Inquire about the warranty terms carefully. Are repairs covered? What about replacement parts? Clarifying these details can save you money and hassle in the future.

While evaluating prices and warranties, reflect on your production needs. Sometimes, a higher-priced machine with a robust warranty can prove to be more economical over time. A balance between cost and reliability is vital. Many buyers overlook this aspect and suffer the consequences later. Taking time to research thoroughly pays off in the long run.