In the competitive world of manufacturing, the demand for high-quality products is relentless. Industries rely on High Quality Steel Pipe Machines Tube Mill to deliver performance and durability. These machines play a crucial role in producing steel pipes that meet stringent quality standards.

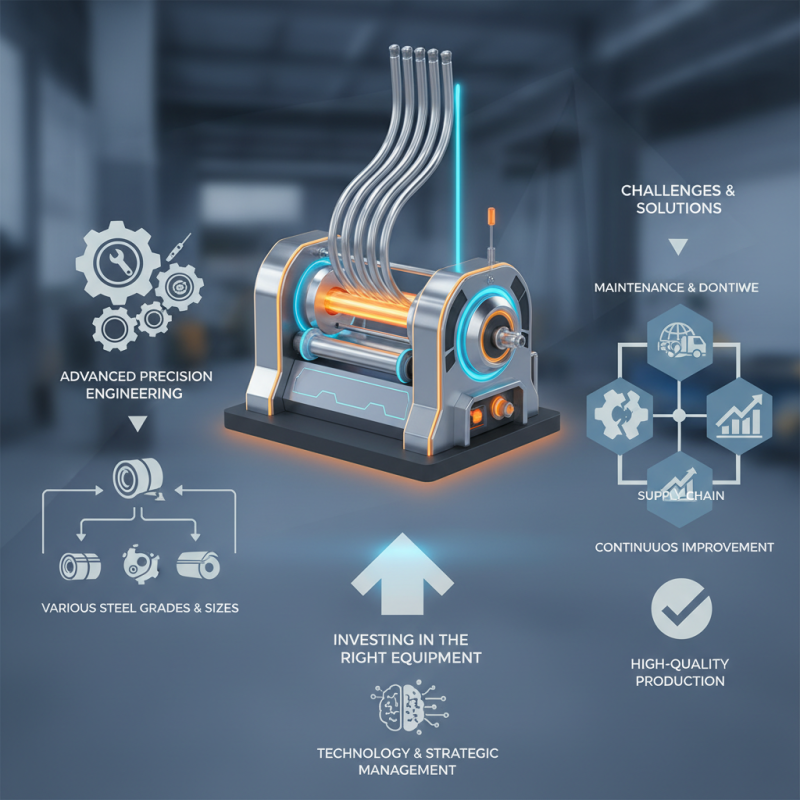

Advanced tube mills ensure precision in every cut and weld. They are engineered to handle various steel grades and sizes. However, the journey to achieving optimal production is not without challenges. Manufacturers must navigate issues like maintenance, downtime, and supply chain delays. These factors can impact overall efficiency and product quality.

Investing in the right equipment is vital. Yet, even with the best machines, there are risks involved. Mistakes can lead to material waste and increased costs. Continuous improvement is essential for staying competitive. Evaluating machine performance regularly helps identify areas for enhancement. Ultimately, high-quality production relies on both technology and strategic management.

The manufacturing of steel pipes involves various techniques and processes that ensure quality and efficiency. The journey typically begins with the selection of raw materials. Steel coils are often used as the starting point. These coils go through a series of formation stages, including shearing and welding. However, consistency in steel quality can sometimes be challenging, as variations can lead to defects.

Once the basic shape is formed, the pipes undergo further processing. This includes sizing and straightening. Sizing mills play a crucial role here. They ensure that the pipes are uniform in diameter. By applying precise measurements, these mills enhance product quality. Yet, issues can arise during high-speed operations. Misalignment or equipment wear may affect output.

In the final stages, pipes are subjected to rigorous testing. Non-destructive testing methods help to identify hidden flaws. Such practices are essential to ensure safety and reliability. Quality control must be an ongoing effort. Each defect caught can save future complications. Overall, while the steel pipe manufacturing process is advanced, it is not without its challenges. Continuous improvement and refinement are vital for achieving high standards.

In the world of steel pipe production, high-quality tube mills play a crucial role. These machines are designed with precision and efficiency in mind. Key features like adjustable speed settings allow operators to fine-tune the production process. This flexibility can enhance overall product quality. Additionally, robust welding systems ensure strong seams, vital for the structural integrity of pipes.

Moreover, advanced automation is becoming increasingly important. Automated controls can reduce human error and increase production rates. However, not all systems are foolproof. Regular maintenance is essential to prevent breakdowns. Operators must invest time in training to fully utilize these advanced machines.

Lastly, quality assurance mechanisms built into tube mills help in monitoring the production process. Sensors can detect anomalies in real-time. This technology supports quick adjustments. Despite these advantages, human oversight remains necessary. Balancing automation with skilled labor can lead to the best outcomes in steel pipe production.

The steel pipe manufacturing industry has seen significant innovations in recent years. Major manufacturers are continually improving their tube mills to enhance production quality. Data from industry reports indicate that advancements in technology have led to a 15% increase in efficiency for modern tube mills. This has been achieved through enhanced automation and the use of advanced materials in machinery.

Collaboration between manufacturers and technology experts is becoming common. Innovative techniques like the use of laser welding and high-frequency induction are gaining traction. These methods have not only improved weld quality but also reduced production times. However, the high initial investments in these technologies pose a challenge for smaller manufacturers. Many are hesitant to adopt new machinery due to financial constraints.

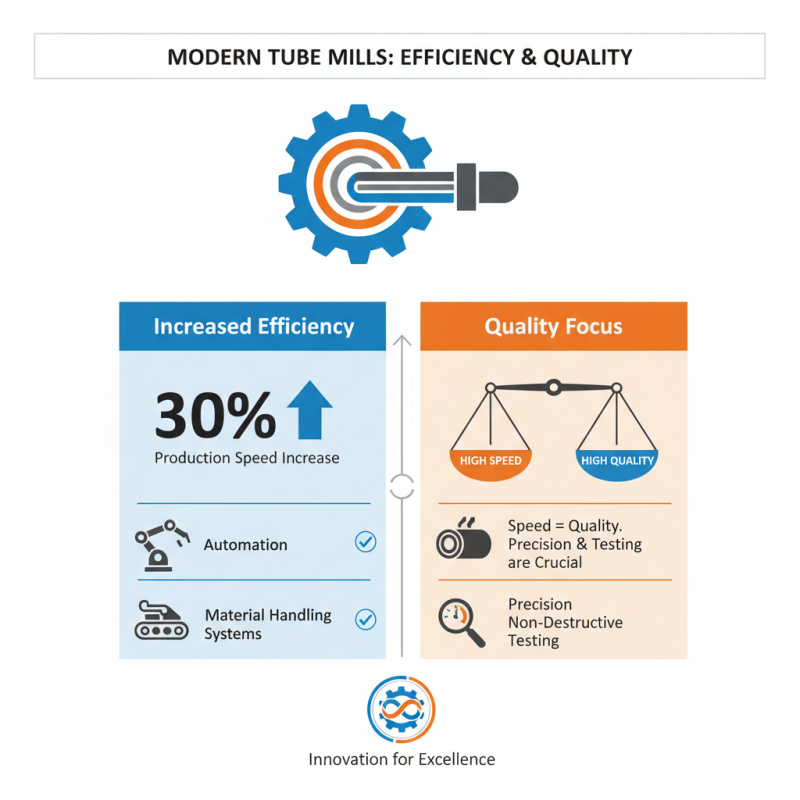

The evolution of steel pipe machines is a double-edged sword. While larger players benefit from rapid advancements, smaller firms may struggle to keep up. They must find a balance between upgrading equipment and maintaining profitability. Recent reports suggest that companies committing to innovation are 30% more likely to maintain market share. However, the road to modernization requires careful planning and evaluation.

| Machine Type | Production Capacity (Tons/Year) | Pipe Diameter Range (mm) | Material Type | Special Features |

|---|---|---|---|---|

| High-Frequency Welded Mills | 5000 | 20 - 200 | Mild Steel, Stainless Steel | Automated Welding Control |

| ERW Tube Mills | 8000 | 10 - 150 | Carbon Steel | Eco-Friendly Energy Usage |

| Seamless Pipe Mills | 6000 | 30 - 300 | Alloy Steel | High Precision Manufacturing |

| SPIRAL Welded Pipe Mills | 3000 | 100 - 1000 | Carbon Steel, Stainless Steel | High Strength Applications |

When selecting tube mills, it’s essential to understand their capabilities. Each machine has unique features that cater to various production needs.

A comparative analysis of several tube mills reveals differences in efficiency and quality output.

Tips: Consider the production volume. Higher capacity machines may seem ideal, but they may also require more maintenance. A balance between output and upkeep is crucial. Some mills are designed for specific materials, which can limit versatility.

Another factor to contemplate is the level of automation. Fully automated systems can enhance productivity. However, they often come with higher initial costs. Assessing the long-term benefits of automation can lead to better decision-making. Not all mills will provide a seamless operational experience. Frequent adjustments may be needed to maintain quality.

Sometimes, price and features can mislead buyers. A cheaper option might not meet quality standards. This scenario leads to increased waste and rework. Investing in a reliable tube mill is key to high-quality production.

In the competitive world of pipe manufacturing, efficiency and quality are paramount. Tube mills play a critical role in this process. Their design and technology must continually evolve to meet increasing production demands. According to a recent industry report, modern tube mills have increased production speeds by up to 30% due to advancements in automation and material handling systems. However, high speed does not always equal high quality.

Several factors impact the overall effectiveness of tube mills. Operator skills play a significant role in ensuring that machines run smoothly. Training programs are essential, yet they are often overlooked. Poorly trained operators can lead to equipment malfunctions or subpar product quality. Moreover, maintenance schedules must be strictly adhered to. Neglecting routine checks can result in unexpected downtimes. A study revealed that frequent unscheduled maintenance can reduce production efficiency by up to 15%.

The quality of raw materials is another crucial element. Substandard materials can compromise the integrity of the finished product. Inspecting materials before processing is necessary but often inefficiently implemented. Failing to conduct thorough checks can result in defects that are costly to correct down the line. Hence, continuous evaluation of processes and equipment is vital for manufacturers aiming for excellence in production and product quality.