In the rapidly evolving landscape of manufacturing, businesses are increasingly turning to innovative solutions to enhance efficiency and productivity. One such solution that has gained significant attention is the Square Tube Machine. Renowned expert in metal fabrication, Dr. John Stevens, states, "The adoption of square tube machines is revolutionizing the way we approach metalworking, significantly reducing production times while maintaining exceptional quality." This sentiment resonates with many in the industry, as the benefits offered by square tube machines are profound and multifaceted.

The versatility and precision of a Square Tube Machine allow manufacturers to achieve a wide array of applications, from structural components to intricate designs. With the ability to streamline operations and minimize waste, these machines position businesses to stay ahead of the competition. As more companies recognize the value of automation and advanced machinery, understanding the advantages of the Square Tube Machine becomes critical for leveraging growth opportunities in the market. This article will delve into the top ten benefits of incorporating such machinery into your operations, ensuring that you have the insights needed to make informed business decisions.

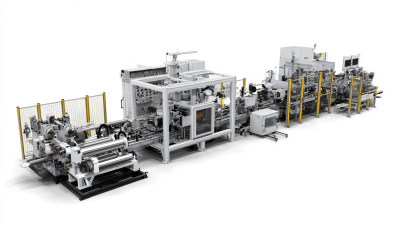

The square tube machine technology has revolutionized the manufacturing sector by offering precision, efficiency, and versatility. At its core, the square tube machine is designed to produce high-quality square or rectangular tubes from a variety of materials. Understanding the mechanics behind this technology can significantly enhance a business's production capabilities. By utilizing advanced techniques such as cold forming and welding, manufacturers can create standardized products with minimal waste, thus improving overall operational efficiency.

Tips: When considering the integration of square tube machines into your production line, it’s essential to assess your current output and identify areas for improvement. Implementing automation features can streamline processes and enhance productivity. Additionally, regularly maintaining your machinery ensures consistent performance and prolongs the equipment’s lifespan.

Moreover, grasping the fundamentals of square tube machine technology includes recognizing the importance of customization. Many machines come with adjustable settings that allow for different sizes and wall thicknesses, catering specifically to the unique requirements of various projects. Businesses that adopt this technology can respond more flexibly to market demands, ultimately gaining a competitive edge.

Tips: Always conduct thorough research on the features that best suit your business needs. Engaging with other manufacturers can also provide valuable insights into optimizing the use of square tube machines in your operations.

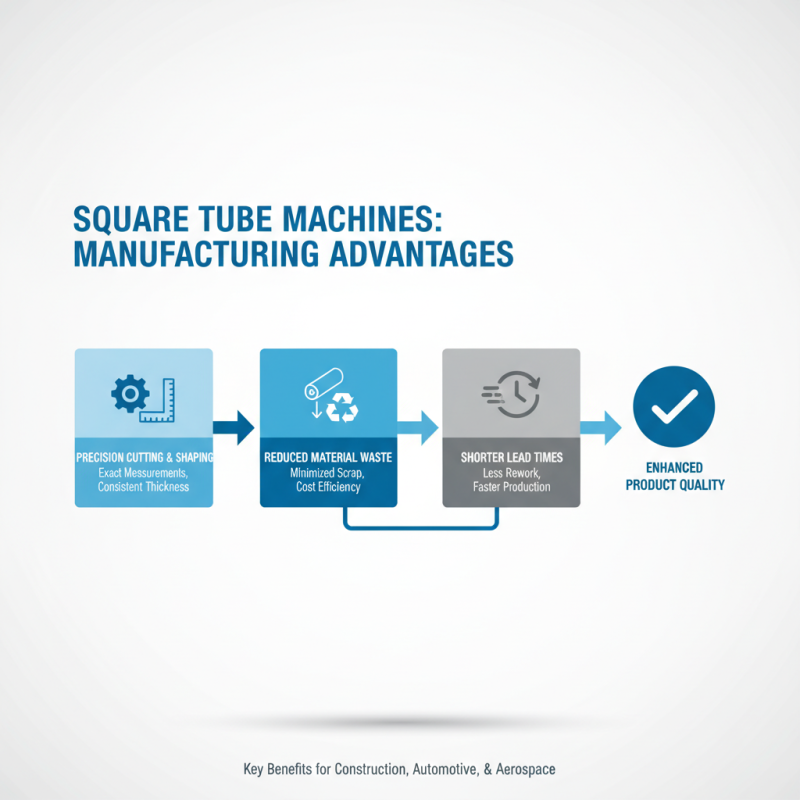

Utilizing square tube machines in manufacturing presents a range of key advantages that can significantly enhance production efficiency and product quality. First and foremost, these machines offer precision cutting and shaping capabilities, which allow manufacturers to create square tubes with exact measurements and consistent wall thickness. This level of accuracy is crucial in industries where tolerances are tight and product integrity is vital, such as in construction, automotive, and aerospace sectors. The enhanced precision not only reduces material wastage but also minimizes the need for secondary operations, leading to shorter lead times.

Another important benefit of square tube machines is their versatility in processing various materials, including aluminum, steel, and stainless steel. This adaptability enables manufacturers to meet diverse customer demands without the need for multiple specialized machines. Furthermore, the automation features commonly found in modern square tube machines streamline the manufacturing process, reducing labor costs and enhancing safety by minimizing manual handling. By integrating these machines into their production lines, companies can improve operational efficiency while maintaining high standards of quality, ultimately giving them a competitive edge in the market.

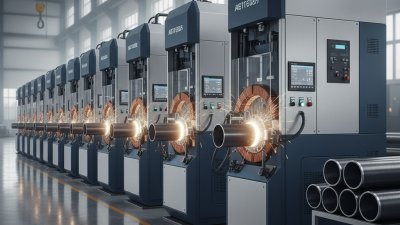

Square tube machines have become essential tools in modern manufacturing, significantly enhancing efficiency and productivity. With the ability to quickly cut, shape, and weld metal into precise configurations, these machines streamline operations and reduce turnaround times. According to a recent report from the Fabricators and Manufacturers Association, 65% of manufacturers have reported a measurable increase in productivity after integrating automated square tube machinery into their production lines. This increase can be attributed to the machines' advanced technology, which minimizes manual labor and reduces human error.

Tips for maximizing productivity with square tube machines include regular maintenance to ensure optimal performance, training staff on proper operational techniques, and utilizing software to optimize cutting patterns. By regularly servicing equipment, companies can avoid unexpected downtime, which can lead to project delays. Furthermore, training employees to operate machines efficiently not only increases safety but also enhances the overall output. Utilizing design software to optimize any cutting plans can further reduce material waste, allowing businesses to save costs and contribute to sustainable practices.

Additionally, investing in square tube machines can provide your business with a competitive edge. Companies that adopt these machines often experience a reduction in production costs by as much as 30%, as reported by the National Association of Manufacturers. This cost-effectiveness allows businesses to allocate resources more effectively, paving the way for innovation and growth within the industry.

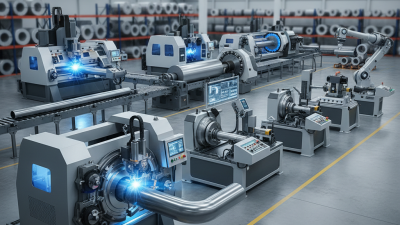

Square tube machines present substantial cost-effectiveness for businesses operating in various sectors. By automating the production of square tubes, these machines significantly reduce labor costs, eliminating the need for extensive manual work. This efficiency not only speeds up the manufacturing process but also minimizes human errors that can lead to material wastage. As a result, companies can produce more in less time, enhancing productivity and allowing for quicker turnaround times on projects.

Furthermore, the use of square tube machines leads to savings in raw material costs through precise cutting and shaping techniques. The machines are designed to optimize material usage, reducing scrap and maximizing the yield from each batch of raw materials. This capability ensures that businesses can maintain lower inventory costs and better manage their resources. Ultimately, the overall reduction in production expenses directly contributes to a healthier bottom line, positioning companies for competitive advantage in their respective markets.

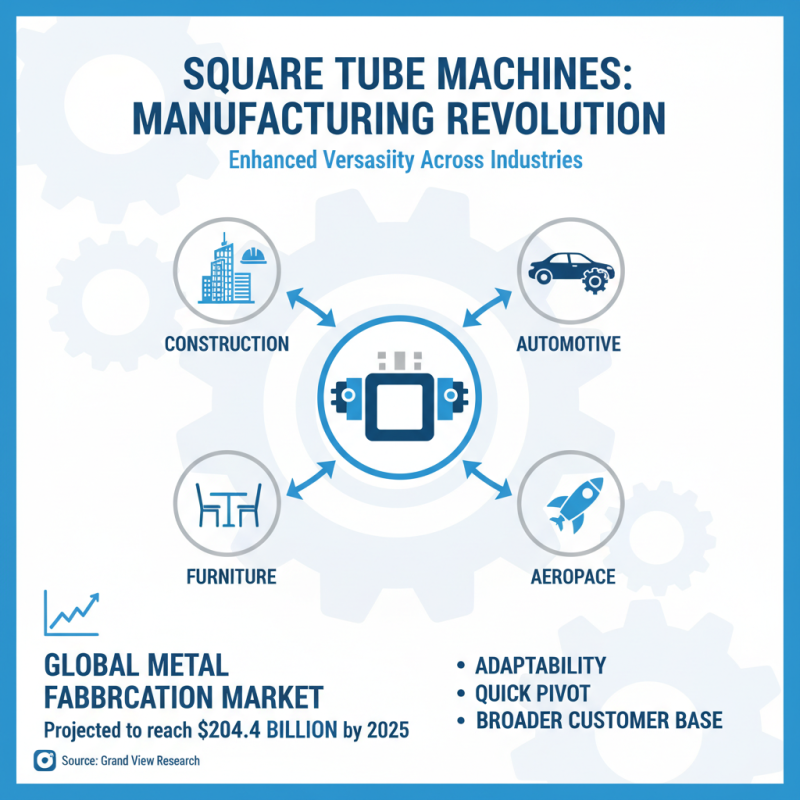

Square tube machines have revolutionized manufacturing processes across various industries due to their enhanced versatility. These machines are not limited to specific tasks; they serve in construction, automotive, furniture production, and even in the aerospace sector. According to a market research report by Grand View Research, the global metal fabrication market, which includes square tube processing, is projected to reach USD 204.4 billion by 2025, signifying the growing demand for versatile manufacturing technologies. This adaptability allows businesses to pivot quickly, respond to industry trends, and cater to a broader customer base.

Another noteworthy application of square tube machines can be found in the green building sector. The increasing emphasis on sustainable construction practices drives the need for efficient materials that reduce waste. Square tubes, being lightweight yet strong, enable architects and builders to create innovative designs while minimizing material use. A report from the U.S. Green Building Council indicates that buildings that incorporate efficient material use can significantly lower energy consumption, highlighting the value of square tube machines in modern construction.

Tip: When selecting a square tube machine for your business, consider the specific applications you intend to use it for. Research your industry standards and identify machines that offer customization options to suit your unique production needs. This can greatly enhance efficiency and product quality.

Tip: Ensure your team is trained on the latest handling techniques for square tube machines, as this can minimize accidents and increase productivity. Investing in proper training can lead to long-term savings by reducing downtime and material waste.