In the world of manufacturing, the "Square Tube Machine" plays a vital role. It revolutionizes how we create square tubes for various applications. Industry expert John Smith states, "The Square Tube Machine increases efficiency and precision in production." This approach shapes modern construction, automotive parts, and furniture.

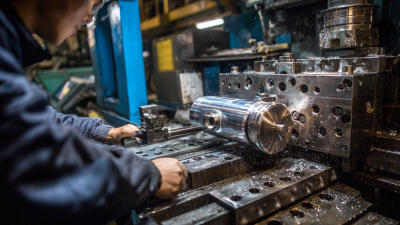

The Square Tube Machine operates using advanced techniques to cut, bend, and assemble metal into square tubing. Observing this machine is fascinating. It combines technology with craftsmanship in a seamless manner. However, achieving the perfect quality takes practice and attention. Each misalignment can lead to structural failures.

As we explore the mechanics of the Square Tube Machine, we uncover its challenges. Machines can malfunction, and skilled operators are essential. A simple error can disrupt production. This reality pushes engineers to innovate continually. They must address both current limitations and future needs in manufacturing. Such reflections lead us to appreciate the complexities of this machinery in our evolving world.

A square tube machine is a specialized piece of equipment. It fabricates square tubes from metal sheets. The process begins with feeding the sheets into the machine. They are then cut and shaped using various rolls and dies. This method allows for precision in dimensions and angles. The square tube machine is popular in sectors like construction and manufacturing.

This machine operates through a series of steps. First, the metal is prepped and aligned. Next, it goes through forming rolls, transforming it into a square shape. The edges are then welded or joined. This process can be complex and requires skill. Operators need to ensure that settings are accurate. A miscalculation can lead to waste. Many find this aspect both challenging and rewarding.

Maintenance is a crucial part of operating a square tube machine. Regular checks can prevent breakdowns. Users often overlook this, leading to inefficiencies. Learning from these mistakes can improve overall performance. Each machine can be unique, adding to the need for careful handling. Understand how it works to maximize its potential.

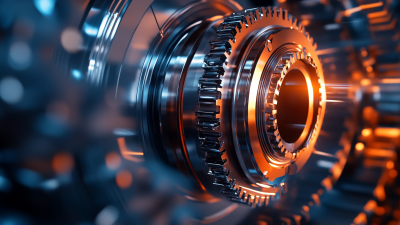

A square tube machine is vital in modern manufacturing. This machine processes metal into square tubes, which are widely used in construction and automotive industries. Understanding its key components helps us appreciate its efficiency.

The primary components include the forming station, cutting station, and hydraulic system. The forming station shapes flat metal sheets into tubes. Precision is crucial here; even a slight error can lead to significant waste. The cutting station then sizes the tubes to required lengths. Accurate measurements are essential for maintaining product quality. A report by the Manufacturing Institute indicates that improper cutting accounts for nearly 20% of material loss.

The hydraulic system powers the machine's movements. It ensures smooth operation and precision. However, maintenance can be a challenge. Neglecting this system may lead to inconsistent performance. Many operators find debugging these machines complicated, often requiring specialized knowledge. Despite the challenges, advances in technology can improve efficiency. Investing in training is vital for operators to fully understand the machine’s nuances.

A square tube machine is a specialized equipment designed to produce square tubes from metal strips. The process begins with feeding flat metal strips into the machine. These strips undergo several forming processes, where they are shaped into a square profile. Rollers within the machine play a crucial role here. They bend the metal steadily and accurately.

During operation, different parts work together seamlessly. The machines use high precision to maintain consistency. This is vital for achieving the desired dimensions. Sometimes, misalignment occurs, resulting in imperfect tubes. Operators must check regularly to ensure everything is aligned properly.

**Tip:** Regular maintenance of the machine can prevent costly downtime. Keep an eye on roller wear and tear. Adjustments should be made to avoid future discrepancies. Forming tools may need replacements over time. This helps maintain the quality of the output.

In addition, operators must be familiar with the machine's operating principles. Understanding how the speed and pressure affect the process is important. A slight change can lead to significant differences in the final product. Regular training can enhance operator efficiency.

| Dimension | Description | Function |

|---|---|---|

| Material Input | Raw metal sheets or strips | Used to create square tubes |

| Cutting Mechanism | Precision cutting through saws or lasers | Cuts raw materials to precise lengths |

| Forming Die | Shaped molds for forming tubes | Shapes the material into square tubes |

| Welding Section | Device for seam welding | Welds edges together to form tubes |

| Cooling System | Water or air cooling | Reduces temperature of welded sections |

| Quality Control | Inspection tools and techniques | Ensures tubes meet specifications |

Square tube machines play a vital role in multiple industries. These machines produce square tubes from flat metal sheets, which is essential for various structural applications. In construction, square tubes are used for framing and support, providing strength and versatility. They are often employed in the manufacturing of furniture, offering a modern aesthetic and durability.

In the automotive sector, square tubes are crucial for vehicle frames and components. Their uniform shape helps in enhancing safety and reliability. Tubes created by these machines are lighter than traditional materials, which can improve fuel efficiency. However, not all square tube machines produce consistent quality. It's essential to monitor production to avoid defects that can affect end products.

The energy sector also benefits from square tube machines. They are used in the creation of robust piping systems and structures for renewable energy installations. Nevertheless, the initial setup can be costly, leading some companies to reconsider their investment. Finding the right balance between quality and cost-effectiveness is often a challenge in this field.

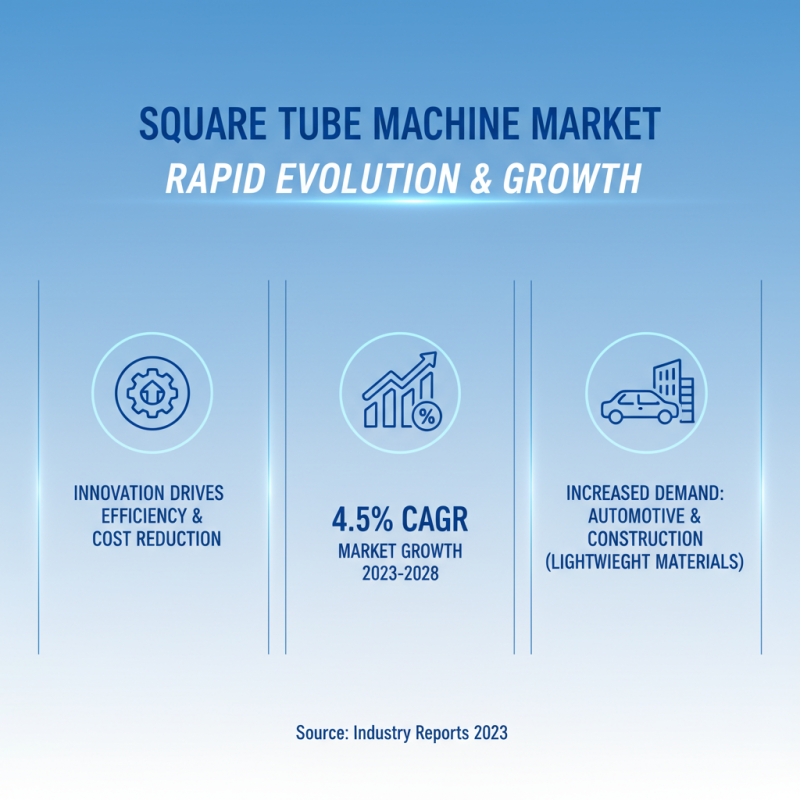

The square tube machine market is evolving rapidly. Innovations are driving manufacturers to improve efficiency and reduce costs. Recent reports suggest that the market growth is projected at a CAGR of 4.5% from 2023 to 2028. This is due to increased demand for lightweight materials in industries such as automotive and construction.

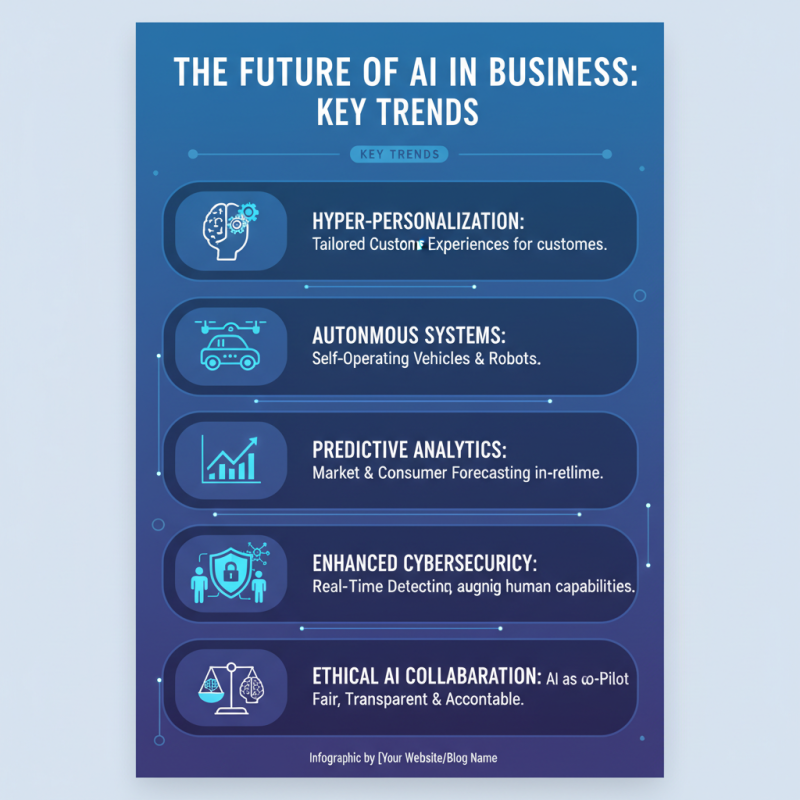

Automation technology plays a crucial role in this transformation. Newer machines utilize advanced software and AI to optimize production. These technologies can minimize waste and enhance precision. For example, predictive maintenance can reduce downtime significantly. Nonetheless, not all manufacturers are adapting quickly. Some still rely on outdated machinery, which can hinder competitiveness.

Tips: Consider investing in automation. It can save costs in the long run. Regularly assess your equipment's efficiency. This step is vital for staying competitive in a fast-changing market. Embracing innovation is not just an option; it's becoming a necessity. The future of square tube machines hinges on those who adapt to these changes.