In today's rapidly evolving industrial landscape, the significance of choosing the right equipment cannot be overstated, especially when it comes to a High Frequency Pipe Making Machine. These machines play a crucial role in the production of high-quality pipes used across various applications, including construction, plumbing, and manufacturing. With a plethora of options available, selecting the most suitable High Frequency Pipe Making Machine for your business needs may seem daunting.

This guide aims to simplify the decision-making process by exploring the various types of machines available, their features, and the factors to consider when making your choice. By understanding the different options and their capabilities, you can ensure that you invest in a machine that not only meets your production requirements but also enhances efficiency and profitability in your operations.

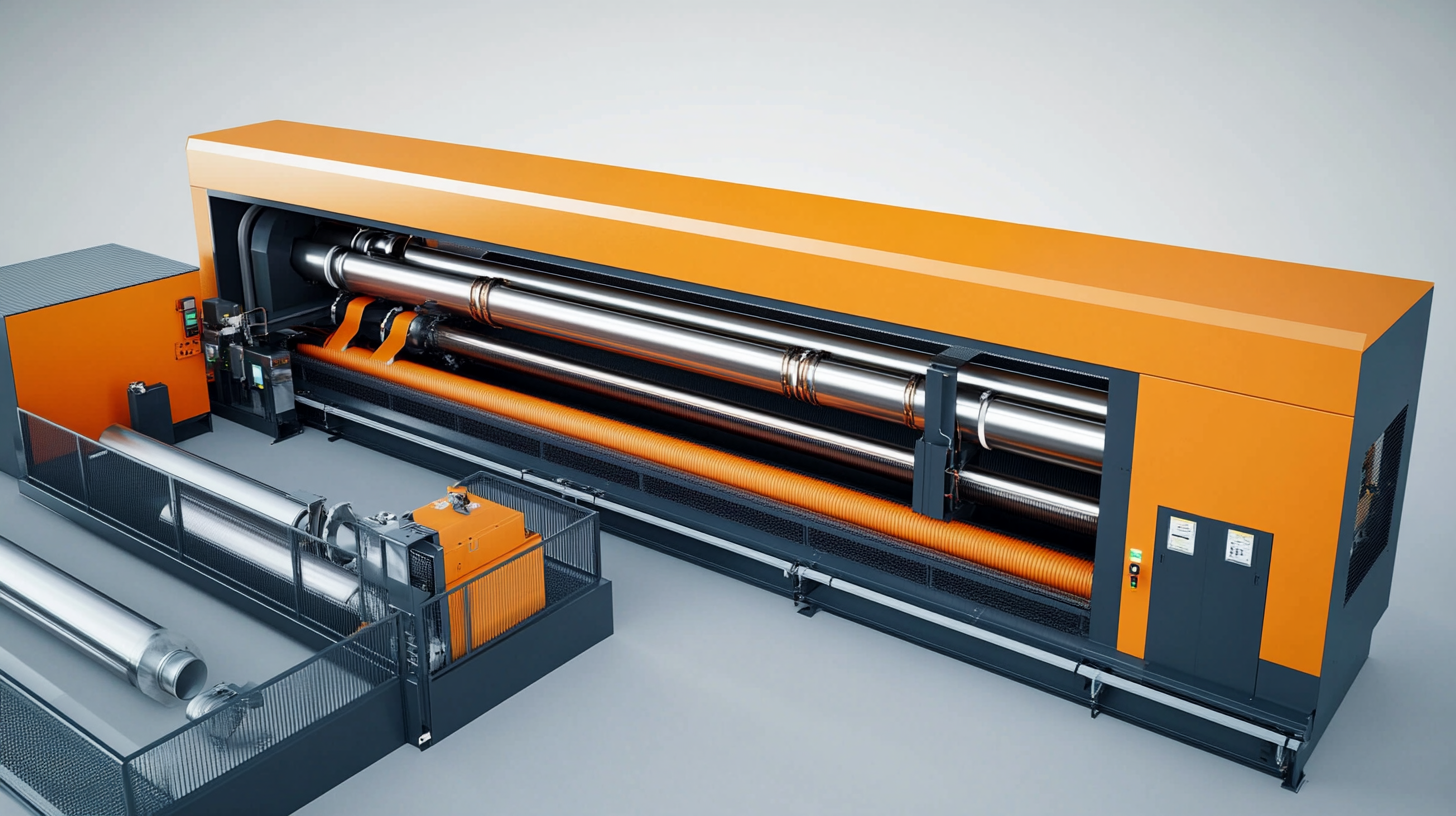

When selecting high frequency pipe making machines for your business, several key features should be considered to ensure they meet your operational needs and enhance productivity. First and foremost, look for machines that offer efficiency in production speed and cycles. A high frequency machine that can produce pipes quickly without compromising on quality reduces downtime and increases overall output.

When selecting high frequency pipe making machines for your business, several key features should be considered to ensure they meet your operational needs and enhance productivity. First and foremost, look for machines that offer efficiency in production speed and cycles. A high frequency machine that can produce pipes quickly without compromising on quality reduces downtime and increases overall output.

Another critical feature is the versatility of the machine. The ability to produce various pipe sizes and types can significantly benefit your business, allowing adaptability to different market demands. Additionally, advanced technology integration, such as digital controls and automation, can improve precision and ease of operation, making it essential to consider machines equipped with modern software and user-friendly interfaces.

Lastly, consider the machine's build quality and maintenance requirements. Durable construction not only extends the lifespan of the machines but also minimizes interruptions caused by repairs. Furthermore, a design that facilitates easy maintenance will keep your operations running smoothly and efficiently, ensuring that your investment in high frequency pipe making machines pays off in the long run.

When selecting high frequency pipe making machines for your business, it’s essential to understand the different types available on the market. Two common types are the high frequency longitudinal welding machines and high frequency spiral welding machines. According to a recent industry report from Grand View Research, the global market for high frequency welding machines is expected to grow significantly, reaching approximately USD 5 billion by 2025. This growth is driven by the increasing demand for high-quality pipes in sectors such as construction and energy.

When selecting high frequency pipe making machines for your business, it’s essential to understand the different types available on the market. Two common types are the high frequency longitudinal welding machines and high frequency spiral welding machines. According to a recent industry report from Grand View Research, the global market for high frequency welding machines is expected to grow significantly, reaching approximately USD 5 billion by 2025. This growth is driven by the increasing demand for high-quality pipes in sectors such as construction and energy.

When comparing these machines, consider their applications, production capacity, and the material thickness they can handle. For example, longitudinal welding machines are typically used for producing straight pipes, while spiral welding machines are preferred for larger diameter pipes, offering flexibility in production. The efficiency and speed of these machines can also vary; longitudinal machines may operate at speeds up to 100 meters per minute, while spiral welders can achieve quality up to 50 meters per minute.

Tip: Always assess your production needs based on your target market and the specifications of the pipes you intend to manufacture. Additionally, conducting a cost-benefit analysis can help determine the best machine choice to optimize your investment and operational efficiency.

When selecting a high frequency pipe making machine, evaluating production efficiency and output quality should be at the forefront of your decision-making process. Production efficiency directly impacts your bottom line; machines that operate at higher speeds and with minimal downtime can significantly increase your output and reduce operational costs. Consider models that offer advanced features such as automatic adjustments and real-time monitoring, which can help streamline processes and maintain consistent quality across production runs.

Output quality, on the other hand, is crucial for maintaining customer satisfaction and adhering to industry standards. High frequency pipe making machines should be able to produce pipes with precise dimensions and a superior finish. Look for machines that include quality control systems and employ high-quality materials to ensure that the final products not only meet regulations but also exceed expectations. Additionally, researching user feedback and performance reviews can help you gauge the reliability of the machines and their capacity to produce high-quality output consistently. This focus on both efficiency and quality will ensure that your investment aligns with your business needs and goals.

When investing in high frequency pipe making machines, understanding essential maintenance tips is crucial for ensuring their longevity and optimal performance. Regular inspections should be a foundational practice; checking for signs of wear and tear can preempt more severe issues down the line. Key components like rollers, motors, and welding sections should be examined frequently. Keeping these parts free from dust and debris not only enhances efficiency but also minimizes operational disruptions.

Another critical aspect of maintenance is lubrication. Many parts of pipe making machines operate under considerable friction, which can lead to overheating and premature wear if not adequately addressed. Utilizing the correct lubricants and adhering to a scheduled lubrication routine can significantly extend the lifespan of your equipment. Additionally, training your staff on proper handling and maintenance protocols plays a vital role in preserving the machinery’s integrity. By fostering a culture of care and attention towards your high frequency pipe making machines, you set the foundation for sustained productivity and reduced downtime.

When investing in high frequency pipe making machines, cost considerations are paramount. A thorough understanding of your budget will dictate the specifications and features you can afford, ultimately influencing the efficiency and scalability of your operations. It’s essential to conduct a comprehensive cost analysis that not only includes the initial purchase price but also factors in maintenance, operational costs, and potential downtime. A well-planned budget will help you avoid overspending while ensuring you select machinery that meets your production needs.

Moreover, consider the long-term financial implications of your choice. Higher-end machines may have a higher upfront cost, but they often come with better energy efficiency and longer lifespans, leading to lower operating costs over time. Additionally, explore financing options, such as installment payments or leasing, to ease the initial burden. Balancing quality and cost will not only enhance your production capabilities but also contribute to the overall profitability of your business.

| Machine Type | Production Capacity (Tubes/Hour) | Power Consumption (kW) | Estimated Cost ($) | Maintenance Cost (Annual) ($) |

|---|---|---|---|---|

| High Frequency Straight Pipe Making Machine | 120 | 30 | 15,000 | 1,200 |

| High Frequency Spiral Pipe Making Machine | 80 | 45 | 25,000 | 1,800 |

| High Frequency Square Pipe Making Machine | 100 | 40 | 20,000 | 1,500 |

| High Frequency Round Pipe Making Machine | 150 | 35 | 18,000 | 1,300 |