In today's fast-paced industrial landscape, efficiency and precision are paramount, particularly in the realm of manufacturing. The Pipe Welding Machine Tube Mill Production Line stands at the forefront of this revolution, transforming traditional methods into streamlined processes that enhance productivity and quality. This ultimate guide delves into the intricacies of these advanced systems, shedding light on their operations, benefits, and best practices. Whether you are a seasoned professional looking to upgrade your machinery or a newcomer eager to understand the essential components of tube mill production, this comprehensive exploration will equip you with the knowledge needed to harness the full potential of pipe welding technologies. Join us as we embark on a journey to revolutionize manufacturing through the innovative capabilities of pipe welding machines and tube mill production lines.

In the realm of manufacturing, understanding the fundamentals of

pipe welding machines

and tube mills is essential for optimizing production efficiency.

The modern tube and pipe production environment is increasingly competitive, demanding that producers

maximize uptime and minimize scrap. According to a recent industry report, an optimal operational efficiency

in tube mills can enhance productivity by up to 30%.

This emphasizes the necessity of investing in high-quality pipe welding machines and well-designed production lines

to achieve these efficiency gains.

Moreover, effective management of material flow and inventory is crucial. A focus on reducing setup times and

implementing just-in-time delivery practices can lead to significantly

shorter production runs, which in turn minimizes waste and increases responsiveness to market demands. As noted

in a two-part series on enhancing tube and pipe mill efficiency, producers are called to adapt swiftly to

partial deliveries and fluctuating market conditions.

This adaptability not only maximizes the utilization of equipment but also ensures a steady output, crucial in a landscape

where demand can vary substantially. By recognizing these fundamentals and leveraging data-driven strategies,

manufacturers can revolutionize their operations and secure a competitive edge.

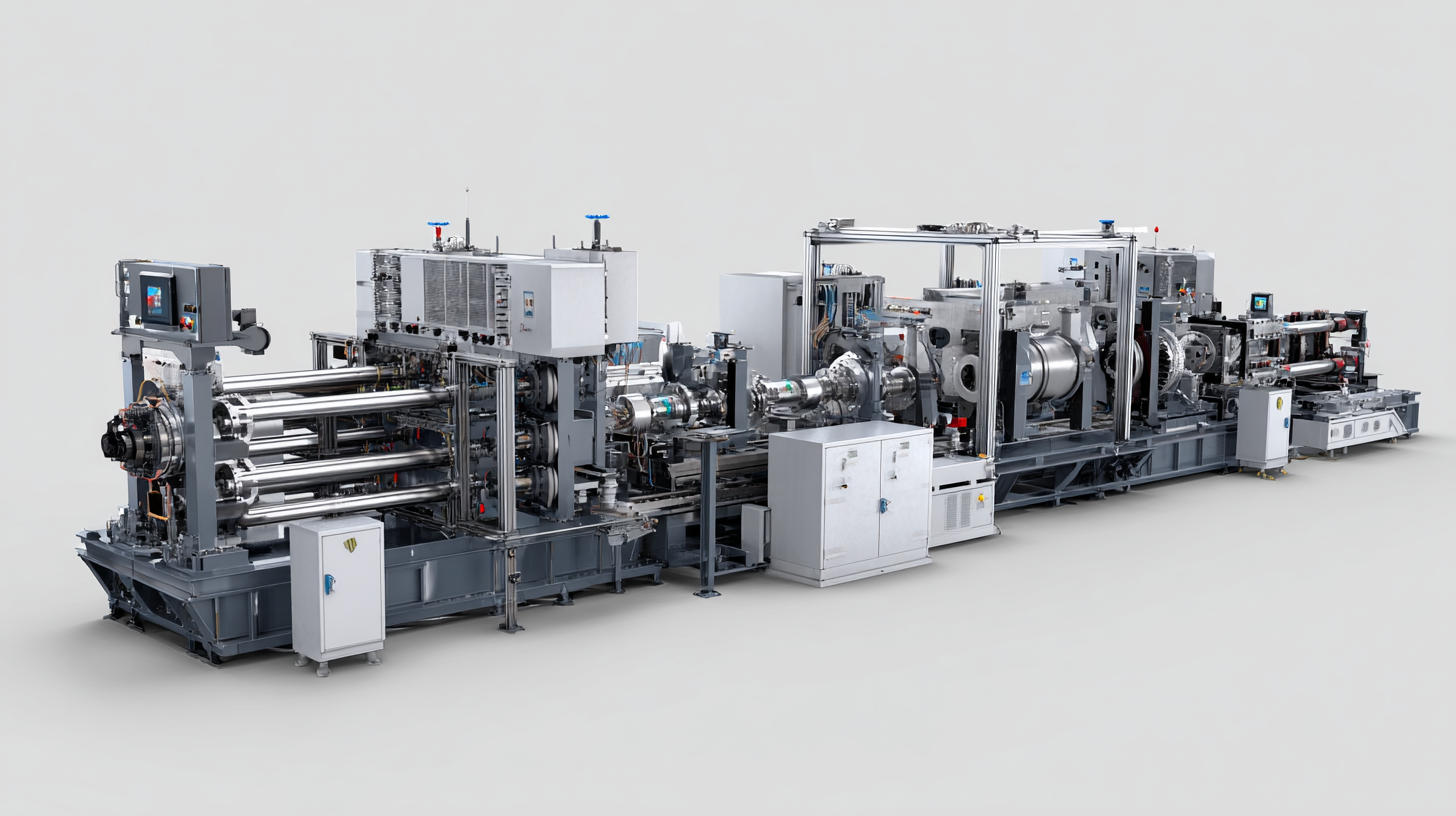

In the ever-evolving landscape of manufacturing, the significance of advanced pipe welding machines cannot be overstated. As per a recent report from MarketsandMarkets, the global market for welding equipment is projected to reach $20 billion by 2026, fueled by innovations in automation and efficiency. When investing in pipe welding machines, it's crucial to focus on key features such as precision control systems, adaptability to various pipe diameters, and robust safety mechanisms. These elements not only enhance operational efficiency but also ensure consistency in weld quality, which is paramount in industries like oil and gas, where structural integrity is non-negotiable.

**Tip:** Always look for machines equipped with real-time monitoring capabilities. This feature allows for instant feedback during the welding process, reducing the likelihood of defects and reworks.

Additionally, energy efficiency has become a vital consideration in the selection of pipe welding machines. According to a report by Research and Markets, welding processes that employ energy-efficient technologies can significantly reduce operational costs by up to 30%. Machines that utilize inverter technology or have the ability to optimize power consumption are becoming increasingly popular.

**Tip:** Consider machines that offer modular designs, allowing for future upgrades without the need to replace entire systems, ensuring long-term viability and adaptability to changing production needs.

Optimizing tube mill production lines is essential for achieving maximum efficiency in manufacturing processes. With the rising costs of raw materials and the competitive nature of the industry, it becomes imperative for manufacturers to squeeze as much performance as possible from their operations. Implementing advanced technologies can lead to significant energy savings and productivity gains.

One effective strategy is to regularly analyze energy consumption indexes and operational efficiencies, much like approaches seen in other industrial sectors. For instance, understanding the energy dynamics can highlight areas where consumption can be reduced, similar to efforts in cement and steel production facilities. This is crucial because mills typically account for a substantial percentage of overall energy use.

Tips for maximizing tube and pipe mill efficiency include focusing on maintenance schedules to ensure minimal downtime and utilizing automation to enhance precision and speed. Additionally, regular training of personnel can lead to better operational practices and more informed decision-making, ensuring that every stage of the production line operates at peak efficiency. Engaging in these practices not only improves yield but also contributes to sustainable production goals.

Proper maintenance and troubleshooting of pipe welding equipment are crucial for maximizing efficiency and ensuring product quality in manufacturing. According to a 2022 report by the International Institute of Welding, improper maintenance can lead to a staggering 20% decrease in production efficiency. Regular checks, including calibration of welding parameters and inspection of wear parts, must be part of a routine practice to prevent potential breakdowns.

Moreover, understanding common troubleshooting techniques can save both time and resources. A study by the Welding Technology Institute indicated that nearly 30% of all welding issues stem from equipment malfunction, often due to neglect or improper setup. For instance, weld inconsistencies can often be traced back to inadequate machine settings or improper use of filler materials. Addressing these concerns promptly not only enhances output quality but can also extend the lifespan of the equipment, ensuring manufacturers maintain their competitive edge in the evolving market.

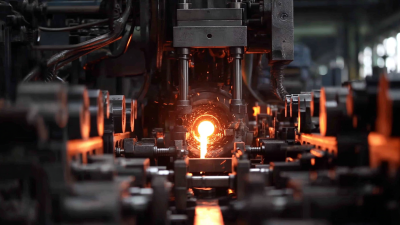

The future of pipe welding and tube mill technologies is poised for significant transformation, with the global seamless stainless steel pipe and tube market projected to reach a value of $5.34 billion in 2024 and grow to $7.21 billion by 2033, reflecting a steady compound annual growth rate (CAGR) of around 3.4%. This illuminating trend underscores the increasing demand across various sectors, such as oil and gas, chemical and petrochemical industries, and construction. As industries strive for efficiency and sustainability, advancements in welding technologies, including methods like arc and resistance welding, will play a pivotal role in enhancing production capabilities.

Moreover, the market for pipe and tube products is not just growing in volume but is also evolving in complexity, with applications extending into critical areas such as automotive, energy, and mechanical engineering. The ongoing innovations in welding machinery and techniques promise improved yield, reduced waste, and enhanced quality control. As manufacturers adapt to these technologies and embrace automation, the industry is likely to witness a robust integration of smart manufacturing processes, setting the stage for a new era in pipe welding and tube mill production that significantly boosts productivity and sustainability.