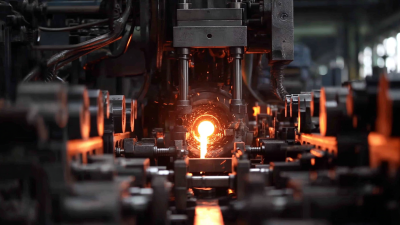

The manufacturing industry is witnessing a transformative shift driven by advancements in technology, particularly with the integration of High Frequency Tube Mill Making Machine innovations. According to a recent market research report by Grand View Research, the global steel pipe market size was valued at USD 273 billion in 2022 and is anticipated to expand at a compound annual growth rate (CAGR) of 6.2% from 2023 to 2030. This surge is significantly influenced by the production capabilities provided by high frequency tube mills, which enhance efficiency and reduce production time, ultimately impacting the overall cost-effectiveness of manufacturing processes.

As highlighted by industry expert Dr. Emily Chen, a leading figure in tube mill technology, "The evolution of the High Frequency Tube Mill Making Machine has not only increased output capacity but also improved the precision of manufacturing, aligning with the demands of modern industries." Such innovations are paving the way for manufacturers to meet the rising consumer expectations for quality and sustainability. Furthermore, the ability of these machines to work with advanced materials is revolutionizing applications in sectors ranging from construction to automotive, ensuring competitive advantages in a rapidly changing marketplace. By exploring the intricacies of how these machines function and their impact on the industry, we can better understand the future landscape of manufacturing.

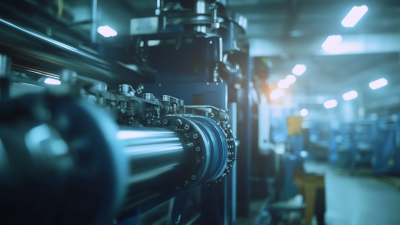

High frequency tube mill making machines are at the forefront of revolutionizing manufacturing processes, particularly within the tube and pipe industry. With advancements in automation and the integration of Industry 4.0 technologies, these machines are enhancing production efficiency and product quality. Recent initiatives by leading engineering groups highlight a shift towards high-end manufacturing, focusing on intelligent systems that streamline operations. According to industry reports, incorporating automation can reduce operational costs by up to 30% while increasing manufacturing capacity significantly.

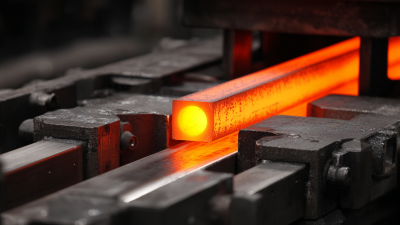

Notably, manufacturers are also investing heavily in research and development to include innovative features in their products. For instance, energy-efficient designs and real-time monitoring systems not only help in minimizing waste but also ensure sustainability within the production environment. The latest trends suggest that facilities equipped with modern high frequency tube mills are capable of reaching an output of 100 machines per year by FY25, which underscores the rapid pace of technological advancement in this sector. By embracing these innovations, companies can position themselves competitively in an evolving market where precision and performance are paramount.

Digital integration in manufacturing processes has become a pivotal factor for enhancing efficiency and driving innovation. The shift towards automation has led to significant cost savings and higher productivity. As companies embrace advanced manufacturing technologies, they can optimize resource utilization, streamline workflows, and ultimately deliver better products to the market. Strategies such as predictive maintenance and real-time data analytics are proving invaluable, allowing manufacturers to preemptively address issues and maintain operational continuity.

Moreover, the advent of AI in supply chain management illustrates the profound impact of digital tools on manufacturing. The transition from Industry 4.0 to Industry 6.0 emphasizes the importance of intelligent integration, where digital twins and modular production systems enable firms to adapt swiftly to changing market demands. This dynamic capability not only enhances competitive performance but also fosters strategic agility, allowing manufacturers to thrive in a fast-evolving landscape. Embracing these innovations is crucial for organizations aiming to stay ahead and leverage new opportunities in today's competitive environment.

Maximizing production efficiency in high-frequency tube mills requires a keen focus on technology and process optimization. One effective approach is to regularly maintain and upgrade equipment. Incorporating advanced sensors and automation technologies can lead to real-time monitoring of performance metrics. This allows manufacturers to quickly identify bottlenecks and make necessary adjustments, ensuring that production runs smoothly and efficiently.

Another important aspect is optimizing the raw material processing stage. Using high-quality materials and precise fabrication techniques can significantly reduce waste and improve the overall quality of the finished products. Implementing lean manufacturing principles can also streamline processes, minimize downtime, and enhance workflow. Training staff on the best practices for operating and maintaining machinery can further enhance productivity, as a skilled workforce is essential for maximizing the benefits of high-frequency technology.

The landscape of tube mill manufacturing is undergoing a significant transformation with the advent of automation and artificial intelligence (AI). These innovations are not just enhancements but are revolutionizing how products are conceived, designed, and produced. Manufacturers are now integrating smart technology that allows for real-time monitoring and adjustments during the production process, leading to increased efficiency and reduced waste. These advancements enable a higher degree of customization, providing manufacturers with the agility to meet diverse customer demands rapidly.

Tip: Implementing AI in your production line can streamline operations. Start small by introducing machine learning algorithms that analyze production data to predict maintenance needs, thus reducing downtime.

Moreover, the future of tube mill manufacturing will see a more collaborative approach between humans and machines. Advanced robotics will handle repetitive tasks, freeing human workers to focus on more strategic roles that require creativity and problem-solving. This shift not only enhances productivity but also improves workplace safety, as machines take over potentially hazardous jobs.

Tip: Consider investing in training programs for your workforce to help them adapt to new technologies. Upskilling employees in AI and automation can lead to higher job satisfaction and loyalty.

As these trends continue to evolve, companies that embrace automation and AI will likely lead the industry in efficiency and innovation.

Maintaining tube mill equipment is crucial for ensuring optimal performance and longevity. Regular inspections are a fundamental practice that allows manufacturers to identify potential issues before they escalate into significant problems. Checking for wear and tear on key components, such as rollers and gears, can help prevent unplanned downtimes. Additionally, keeping a detailed maintenance log assists in tracking the performance trends of the equipment, facilitating timely interventions and replacements as needed.

Another vital aspect of tube mill upkeep is lubrication. Proper lubrication minimizes friction between moving parts, reducing the risk of overheating and mechanical failures. It’s essential to follow the manufacturer's guidelines regarding the type and frequency of lubrication, ensuring that all components receive adequate protection. Furthermore, training the maintenance team to understand the specific needs of high-frequency tube mill machines enhances their ability to perform effective maintenance, ultimately leading to increased efficiency and production quality. By fostering a culture of proactive maintenance, manufacturers can revolutionize their operational capabilities while extending the life of their tube mill equipment.