The evolution of manufacturing, particularly in the realm of metal pipe production, has been significantly marked by advancements in technology, with the Automation Tube Mill Pipe Making Machine leading the charge. According to a report by MarketsandMarkets, the global market for industrial automation is projected to reach $295 billion by 2025, driven by the demand for increased efficiency and reduced labor costs. These machines not only enhance productivity but also ensure high precision in the manufacturing process. As industries seek to optimize operations, the Automation Tube Mill Pipe Making Machine stands at the forefront, offering solutions that integrate speed and quality. This transformative approach not only improves production rates but also contributes to sustainability efforts by minimizing waste and energy consumption, thus reshaping the future of manufacturing.

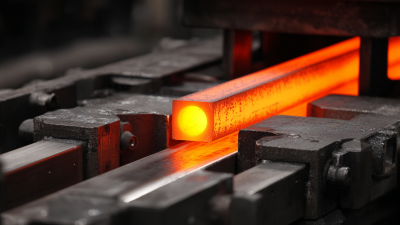

The evolution of tube mill pipe making machines has significantly shaped the manufacturing landscape over the past few decades. Starting from traditional methods in the early 20th century, advancements in technology have led to the development of high-speed, automated systems that enhance efficiency and precision. According to a report by MarketsandMarkets, the global market for tube and pipe manufacturing machines was valued at approximately $12.6 billion in 2022 and is projected to reach $19.2 billion by 2027, growing at a CAGR of 8.6%. This growth is driven by increasing demand in sectors such as construction, automotive, and energy, where high-quality and durable pipes are essential.

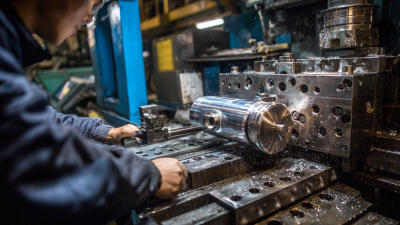

Modern tube mill machines now utilize advanced technologies like programmable logic controllers (PLCs) and robotic systems, which allow for greater flexibility and reduced labor costs. A study by Grand View Research highlights that innovations in automation have resulted in output increases of up to 30% while significantly reducing waste material. Furthermore, the integration of IoT (Internet of Things) into manufacturing processes enhances real-time monitoring and predictive maintenance, leading to improved operational efficiency. As manufacturers continue to seek ways to optimize production, the trend towards automation in tube mill pipe making machines marks a pivotal shift towards smarter manufacturing practices.

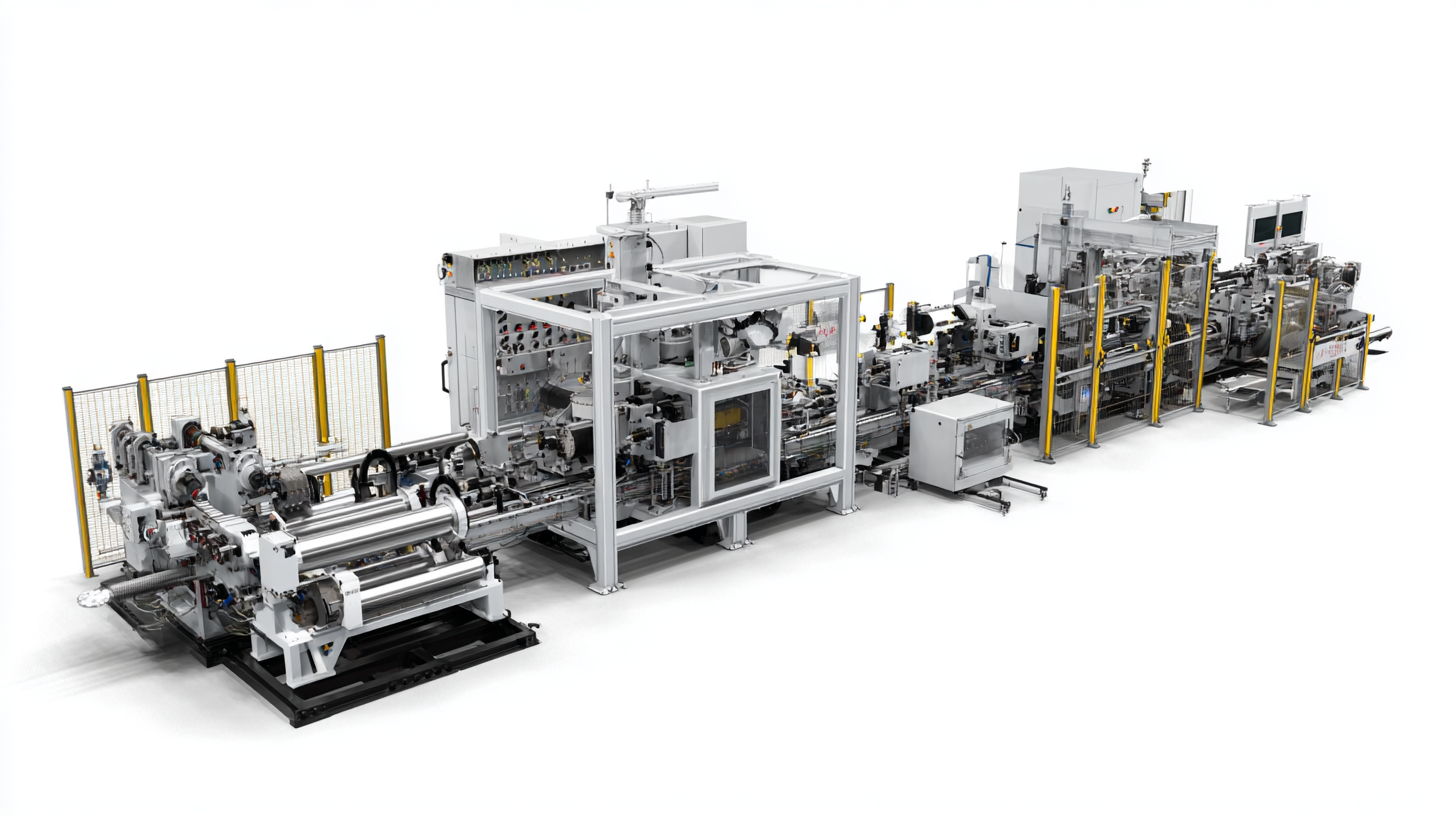

The manufacturing sector is undergoing a significant transformation driven by advancements in automation technologies. A recent report by McKinsey & Company highlights that automation could contribute up to $4 trillion to the global economy in the next decade, particularly within industries like pipe production. The integration of automated tube mill pipe making machines allows manufacturers to enhance efficiency, reduce labor costs, and improve product quality. These machines utilize cutting-edge technologies such as AI and machine learning to streamline production processes, minimizing human error and waste.

Furthermore, the adoption of automation in pipe manufacturing is projected to increase operational capacity by 30% over the next few years, according to a report from the International Federation of Robotics. This shift not only optimizes production lines but also enables real-time data analytics, allowing manufacturers to make informed decisions quickly. With these advancements, companies can respond to market demand more effectively, ensuring that they remain competitive in a rapidly evolving landscape. The future of pipe production lies in the embrace of these automation technologies, paving the way for smarter, more sustainable manufacturing practices.

Modern tube mill machinery represents a significant advancement in the manufacturing sector, bringing unparalleled efficiency and precision to the pipe-making process. One of the key features of these machines is their advanced automation technology, which minimizes human intervention and significantly reduces the risk of error.

This automation not only streamlines operations but also enhances productivity, allowing manufacturers to meet high-demand production schedules without compromising quality.

Another notable advantage of contemporary tube mills is their adaptability. These machines can easily be configured to produce pipes of various sizes and materials, making them invaluable for manufacturers looking to diversify their product offerings. Furthermore, modern tube mills are equipped with sophisticated monitoring systems that provide real-time data analysis, enabling operators to make informed decisions and adjustments on the fly.

This combination of flexibility and intelligence positions tube mill machinery at the forefront of manufacturing innovation, setting new standards for quality and efficiency in the industry.

The integration of Artificial Intelligence (AI) and the Internet of Things (IoT) in manufacturing, known as Industry 4.0, brings about remarkable advancements in efficiency. By connecting devices and leveraging data analytics, manufacturers can achieve unprecedented automation levels, optimize production lines, and reduce costs. However, navigating this new landscape is not without its challenges. Companies must address potential risks such as cybersecurity threats, the need for workforce reskilling, and the complexities involved in system integration.

As manufacturing evolves, industries are poised at a crucial juncture. The growing emphasis on AI integration reflects the commitment to transforming traditional practices into intelligent, data-driven operations. By establishing "lighthouse factories" that showcase best practices in automation and connectivity, manufacturers can illuminate pathways toward successful digital transformation. This shift not only supports higher productivity but also fosters innovation, creating a fertile ground for the next generation of manufacturing excellence.

The pipe making industry is undergoing a transformative phase driven by innovative technologies and automation advancements. The global market for casing, projected to grow from $19.4 billion in 2025 to $29.84 billion by 2032, reflects the increasing demand for efficient and sustainable manufacturing processes. Innovations in tube mill pipe making machines are not only streamlining production but also enhancing the quality and performance of the final products. This shift in focus towards automation is reshaping operational dynamics, allowing manufacturers to optimize resources, reduce waste, and respond swiftly to market demands.

Moreover, as the need for sustainable practices intensifies, the industry is leaning towards materials that support longevity and eco-friendliness. Emerging trends such as lightweight materials, 3D printing capabilities, and surface engineering are becoming critical in developing cutting-edge pipe solutions. Companies are investing in research and development to harness these innovations, which promise to redefine standards in manufacturing efficiency and environmental compliance. The combination of these trends is paving the way for a future where the pipe-making sector not only meets but exceeds the expectations of a rapidly evolving marketplace.

| Feature | Current Trends | Future Innovations |

|---|---|---|

| Automation Integration | Robotic arms for precision | AI-driven manufacturing systems |

| Energy Efficiency | Use of energy-efficient motors | Integration of renewable energy sources |

| Customization | Modular machine designs | On-demand production capabilities |

| Material Utilization | Recycled materials usage | Smart material management systems |

| Data Analytics | Basic production monitoring | Predictive maintenance using big data |