In the ever-evolving landscape of manufacturing, the Tube Mill Production Line stands at the forefront of technological advancements, significantly enhancing operational efficiency and product quality. According to the Market Research Future report, the tube and pipe market is projected to grow substantially, with an expected market value reaching $90 billion by 2026. This growth is driven by increasing demand across various industries, including construction and automotive. As manufacturers strive to optimize production capabilities, implementing advanced technologies within the Tube Mill Production Line becomes critical.

Innovations such as automated welding systems, real-time monitoring sensors, and energy-efficient designs not only streamline processes but also minimize waste and reduce production costs. This comprehensive guide will explore effective strategies and technologies available to optimize your Tube Mill Production Line, ensuring you remain competitive in this dynamic market.

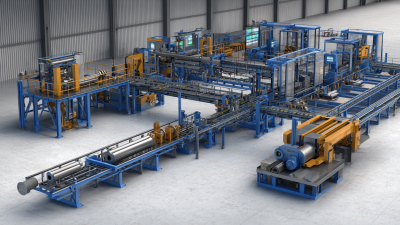

Understanding the fundamentals of tube mill production line technologies is crucial for achieving optimal efficiency in manufacturing processes. Tube mills are essential in producing various tubular products used in construction, automotive, and energy sectors. At their core, these production lines involve multiple stages: from raw material handling to forming, welding, and finishing. Mastering each stage allows manufacturers to fine-tune their processes, reduce waste, and enhance product quality.

Tips: Regular maintenance of mill components is vital for uptime. Schedule periodic inspections to identify wear and tear, ensuring the equipment operates smoothly. Implementing a robust training program for staff can also enhance operational efficiency. Knowledgeable operators can detect issues early and maintain optimal settings, thereby minimizing downtime.

Advancements in tube mill design and functionality have revolutionized the manufacturing landscape, leading to enhanced efficiency and precision in production. One significant innovation is the integration of automated control systems, which allows for real-time monitoring and adjustments during the manufacturing process. These systems optimize parameters such as speed, temperature, and pressure, ensuring that each tube meets stringent quality standards. Moreover, the implementation of advanced predictive maintenance tools minimizes downtime by anticipating equipment failures before they occur, thereby maximizing operational efficiency.

Another key innovation is the development of modular tube mills, which offer flexibility in production configurations. These mills can be easily reconfigured to accommodate different tube sizes and materials, resulting in reduced setup times and increased versatility. Additionally, advancements in materials science have led to the use of high-strength, lightweight materials in mill construction, improving durability and reducing energy consumption during operation. Together, these innovations highlight a significant leap forward in tube mill technology, enabling manufacturers to meet the growing demands of various industries with agility and precision.

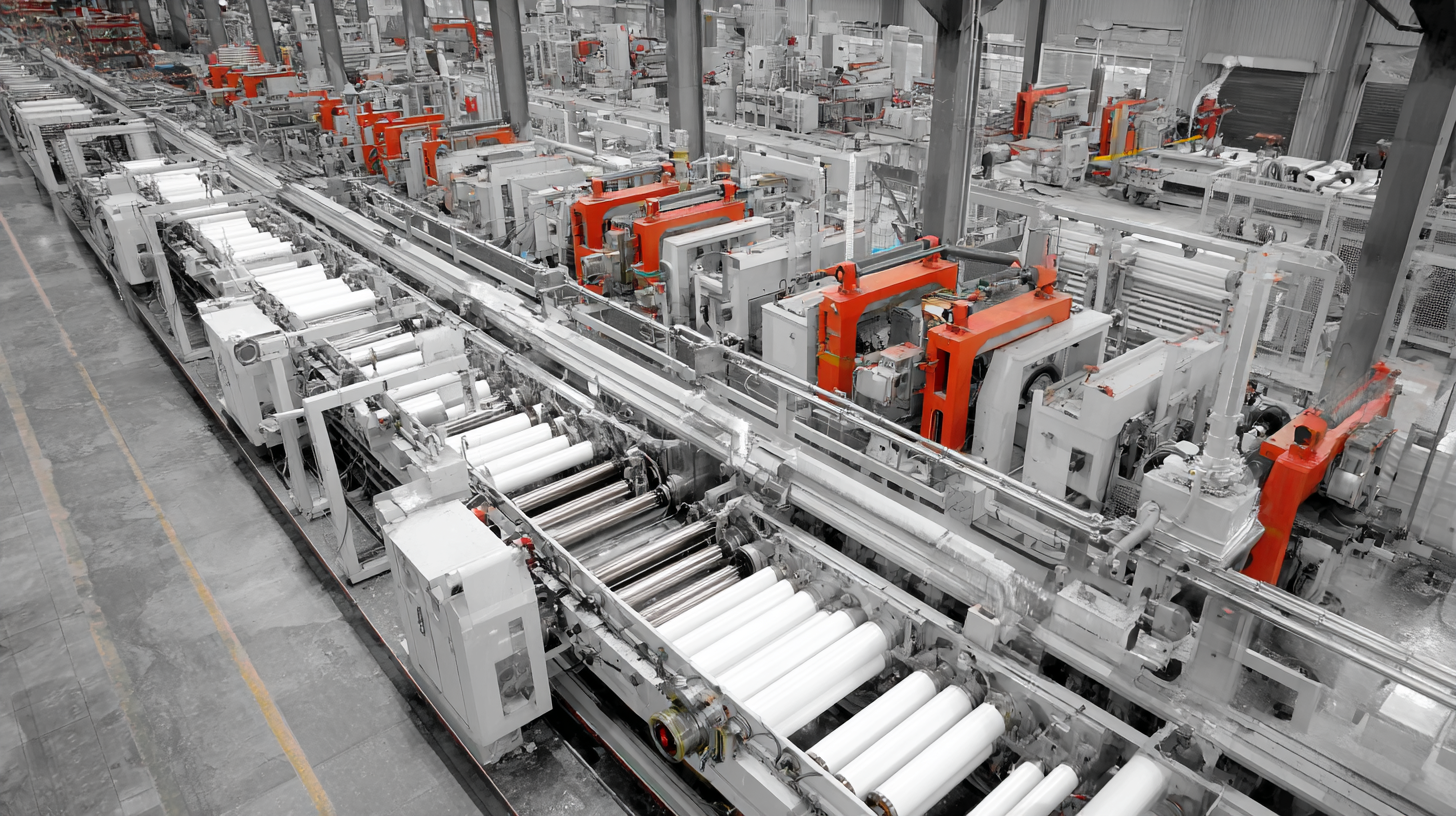

In the fast-evolving landscape of advanced manufacturing, enhancing production efficiency through automation solutions has become paramount. The integration of IoT, 5G networks, and big data analytics is reshaping the industry, driving significant growth. Big data, in particular, emerges as a crucial trend in intelligent manufacturing, leveraging both structured and unstructured data. This influx of data enhances the capabilities of automation technologies, leading to smarter decision-making and streamlined operations.

**Tips:** To maximize the potential of big data in your production line, consider investing in real-time data analytics tools. These tools can provide insights into operational efficiency and identify areas for improvement. Additionally, utilizing digital twin technology can lead to enhanced simulations, allowing for more precise manufacturing processes and innovative product designs.

Collaboration between tech giants is also vital in this journey. For instance, partnerships focused on AI-driven applications are proving effective in boosting industrial productivity. By adopting advanced automation solutions and smart technologies, manufacturers can achieve significant improvements in both efficiency and innovation, setting the stage for a new era of production excellence.

**Tips:** Don't overlook the value of cross-company collaborations; they can open doors to shared knowledge and innovative solutions. Regularly assessing your tech stack and upgrading where necessary ensures that your production line remains competitive and efficient amidst rapid technological advancements.

| Technology | Description | Efficiency Improvement (%) | Cost Reduction (%) | Implementation Time (Weeks) |

|---|---|---|---|---|

| Automated Material Handling | Utilizes conveyor systems and robotic arms for material transport. | 30 | 15 | 10 |

| Advanced Process Control | Real-time monitoring and adjustment of parameters for optimal production. | 25 | 10 | 8 |

| Data Analytics Integration | Analyzes production data for decision-making and predictive maintenance. | 20 | 12 | 6 |

| Robotic Welding Systems | Automates welding processes to enhance speed and quality. | 40 | 20 | 12 |

| Energy Efficient Motors | Reduces energy consumption while increasing drive efficiency. | 15 | 8 | 4 |

In the competitive world of tube manufacturing, implementing robust quality control measures is paramount for ensuring product consistency and reliability. According to a report from the International Tube Association, approximately 30% of production defects stem from inadequate quality control protocols, emphasizing the necessity of integrating systematic inspection processes within the manufacturing workflow. By utilizing advanced technologies like automated visual inspection systems, companies can significantly reduce defect rates, leading to improved customer satisfaction and lower return rates.

Moreover, incorporating real-time monitoring technologies allows manufacturers to track quality metrics throughout the production process. A study from the Manufacturing Quality Journal revealed that companies adopting such measures reported a 20% increase in production efficiency alongside a dramatic reduction in waste materials. Strategies such as Statistical Process Control (SPC) not only focus on identifying variations in the manufacturing process but also facilitate immediate corrective actions. This integration of quality control within tube manufacturing not only ensures adherence to international standards but also positions companies to compete more effectively in the market.

In the ever-evolving world of manufacturing, sustainability has emerged as a cornerstone of modern tube mill operations. As industries strive to reduce their carbon footprint, tube mills are adopting practices that not only enhance efficiency but also promote environmental stewardship. Utilizing advanced technologies such as energy-efficient drives and regenerative braking systems, manufacturers can minimize energy consumption while maintaining high production standards.

Tips: Consider implementing a waste-reduction strategy in your tube mill operations. This can involve recycling scrap materials and optimizing production schedules to reduce downtime and material waste. Regular audits of energy use can also identify areas for improvement, leading to significant cost savings and a more sustainable operation.

Furthermore, the integration of renewable energy sources is gaining traction. Solar panels and wind turbines can power tube mill facilities, decreasing reliance on fossil fuels. Engaging in supplier partnerships focused on sustainability can reinforce these efforts, ensuring that the materials used are sourced responsibly.

Tips: Explore options for collaboration with local suppliers who focus on sustainable practices. Not only does this support the local economy, but it also enhances the sustainability profile of your products. Regular training for employees on sustainability best practices can foster a culture of environmental awareness within the organization.