In the competitive manufacturing landscape, optimizing production efficiency is paramount, particularly for operations relying on a Tube Mill Production Line. According to a report by the International Tube Association, the global market for tube and pipe manufacturing is projected to reach $12 billion by 2025, driven by the increasing demand for innovative building materials and energy solutions. However, the effectiveness of a Tube Mill Production Line heavily depends on its ability to minimize downtime, enhance throughput, and reduce material waste.

To achieve these objectives, manufacturers must adopt advanced technologies and best practices tailored to their specific processes. For instance, implementing real-time monitoring systems can yield significant gains in operational efficiency—trustworthy data sources indicate that companies employing such technologies can reduce production costs by up to 20%. Additionally, regular maintenance schedules and personnel training play critical roles in ensuring that machinery operates at optimal levels. By focusing on these fundamental aspects, businesses not only enhance their Tube Mill Production Line operations but also position themselves strategically within a growing industry that demands higher quality and faster delivery times.

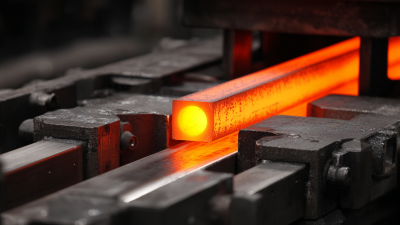

The tube mill production line is essential in various industries, including metal processing, mining, and cement production. Understanding the key components of these lines helps optimize their efficiency. Components such as tube mill liners, which come in various materials like rubber and composite compounds, play a crucial role in determining the performance and durability of the mill. Each type of liner offers unique benefits; for instance, metal liners provide strength and wear resistance, while rubber liners offer lower noise levels and reduced weight.

The market for tube mill production lines is characterized by steady growth, driven by the rising demand for efficient manufacturing processes. Companies are increasingly focusing on enhancing production lines to minimize downtime and maximize output. This involves not only selecting the right type of mill liners based on specific applications but also integrating advanced technologies to monitor and adjust the production parameters in real-time. Such strategic investments are essential for industries aiming to increase their competitiveness in a rapidly evolving market landscape.

In optimizing a tube mill production line, identifying common inefficiencies is essential for enhancing overall performance.

One prevalent inefficiency is the inadequate alignment of roller systems. Misalignment can lead to increased wear on the machinery, reduced product quality, and more frequent breakdowns, which disrupt the production flow. Regular maintenance and precision adjustments can alleviate these issues, ensuring that the rollers work effectively and uniformly.

Another common inefficiency arises from poor material handling processes. Delays in loading raw materials or in the transfer of finished products can bottleneck the entire operation.

Implementing a streamlined logistics plan that includes automated handling systems can significantly reduce waiting times and enhance throughput. Additionally, training employees on efficient material flow and minimizing manual handling can further optimize the production line, leading to higher productivity and reduced operational costs.

Implementing automation in your tube mill production line is a strategic move to enhance efficiency and productivity. According to a report by the International Federation of Robotics, the adoption of industrial robots is anticipated to grow at an annual rate of 13% through 2025, underscoring the importance of automation in manufacturing sectors, including tube mills.

By integrating automated systems, manufacturers can reduce human error, improve precision, and increase throughput. For example, automated material handling systems can streamline the transport of raw materials to the production line, resulting in a significant reduction in cycle time.

Moreover, advanced automation technologies such as predictive maintenance and real-time monitoring systems can revolutionize the operational framework of tube mills. A study published in the Journal of Manufacturing Science and Engineering indicates that companies utilizing predictive maintenance can decrease unplanned downtime by up to 30% and extend equipment life by 20%. This shift not only leads to more efficient production processes but also substantially reduces operational costs. By embracing automation, tube mill operations can achieve a more streamlined workflow, ultimately positioning themselves as leaders in a competitive market.

Utilizing data analytics in the tube mill production line can significantly enhance performance by identifying inefficiencies and optimizing processes.

By collecting and analyzing data from various stages of production, manufacturers can pinpoint

bottlenecks that slow down operations. For instance, real-time monitoring of equipment performance can reveal patterns that indicate when maintenance is needed,

preventing unplanned downtimes and extending equipment life. This proactive approach allows for timely interventions that minimize disruptions.

Moreover, advanced analytics can help in optimizing the operational parameters of the tube mill. By leveraging historical data, manufacturers can establish optimal settings for parameters such as temperature, speed, and pressure, tailored to specific production goals.

Predictive analytics can forecast production outcomes based on different configurations, enabling facilities to simulate changes before implementation.

This data-driven decision-making process not only boosts productivity but also enhances product quality by ensuring consistent performance throughout the manufacturing cycle.

In the pursuit of maximum efficiency within tube mill operations,

training and workforce optimization

play pivotal roles. Industry studies indicate that well-trained employees can enhance production rates by up to 30%.

As tube mill processes become increasingly complex, it is essential for companies to invest in

robust training programs that equip workers with the necessary skills to adapt

to modern machinery and operational techniques. This ensures not only higher production yields but also a reduction in

error rates, which can significantly impact throughput and overall efficiency.

Moreover, embracing workforce optimization strategies can further enhance tube mill performance. By utilizing

data-driven approaches, companies can analyze employee productivity

and workflow efficiencies. For instance, the implementation of real-time monitoring systems

allows managers to make informed adjustments on the fly, ensuring that personnel are effectively utilized throughout the production cycle.

Reports suggest that mills implementing such systems experience a 20% increase in operational efficiency.

By prioritizing training and leveraging workforce analytics, tube mills can navigate the challenges of modern production environments

and achieve their efficiency goals.