In today’s competitive manufacturing landscape, optimizing production lines has become imperative for businesses aiming to enhance efficiency and reduce costs. According to a report by the International Steel Association, the demand for carbon steel pipes is projected to grow by 4% annually, driven by the booming construction and energy sectors.

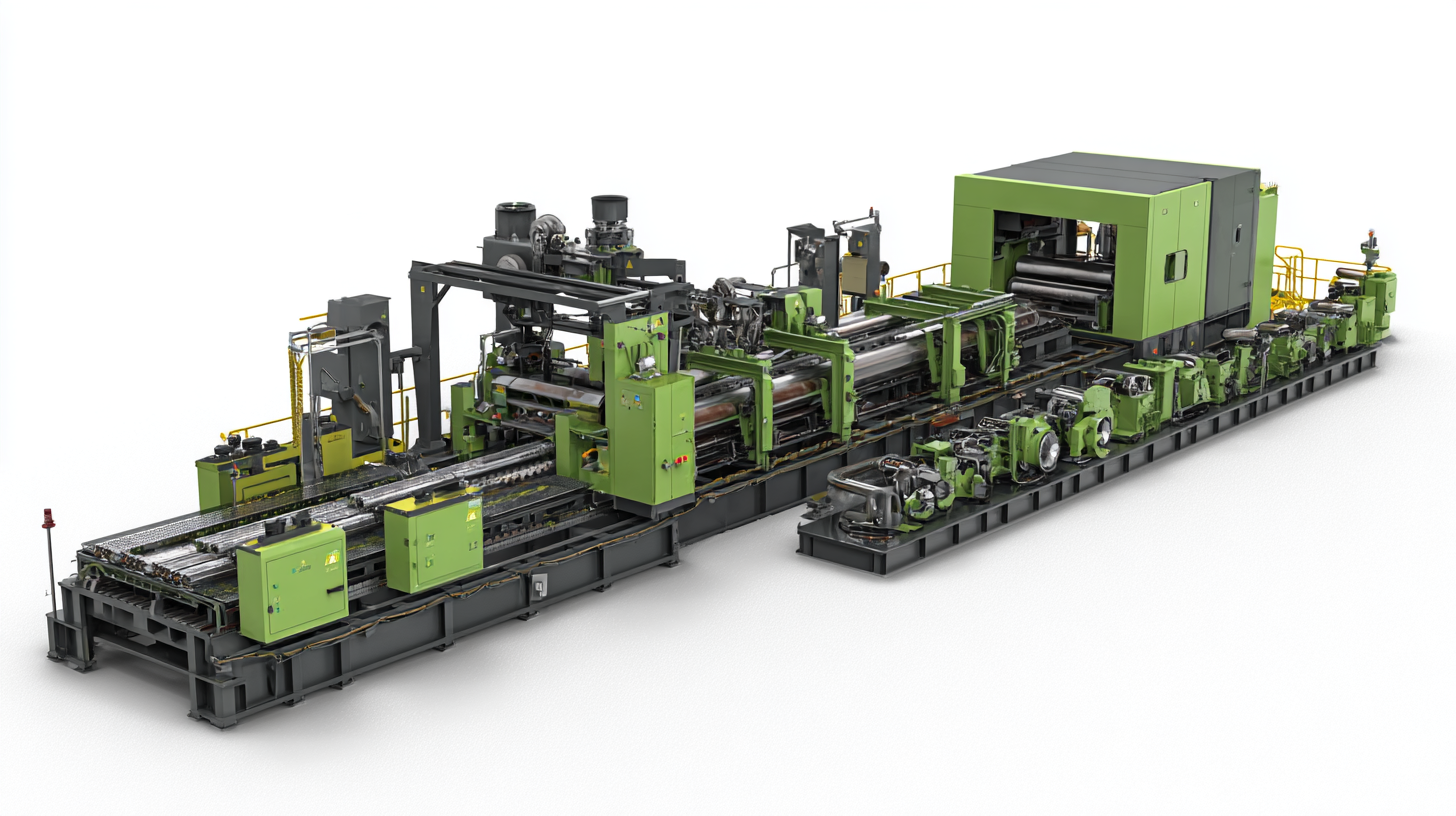

One crucial element in meeting this demand is the use of advanced Carbon Steel Pipe Making Machines. These machines not only streamline production processes but also significantly improve the quality and consistency of the finished products. With the surge in global infrastructure projects and the increasing need for durable piping solutions, integrating effective carbon steel pipe making technology can lead to substantial operational benefits and market competitiveness.

Carbon steel pipe making machines are vital in modern manufacturing, providing high efficiency and quality in the production process. These machines operate by transforming raw carbon steel into pipes through processes such as welding, extrusion, and forming. According to a report by Grand View Research, the global carbon steel pipe market size was valued at approximately $70 billion in 2020 and is projected to expand at a compound annual growth rate (CAGR) of 5.1% from 2021 to 2028. This growth can be directly linked to the advancements in production technology, which have significantly improved the capabilities of carbon steel pipe making machines.

Understanding the basics of these machines helps manufacturers to optimize their production lines effectively. For instance, key parameters such as wall thickness, diameter, and pipe length can be tailored to meet specific industry requirements, ranging from oil and gas to construction applications. According to a report by Markets and Markets, the increasing demand for durable piping solutions has propelled the need for innovative pipe-making technologies. By investing in high-quality carbon steel pipe making machines, manufacturers can enhance productivity while ensuring adherence to stringent quality standards, ultimately leading to cost-effective operations.

When optimizing a production line with carbon steel pipe making machines, it's vital to focus on the key features that can significantly enhance operational efficiency. One crucial aspect to consider is the machine's automation capabilities. Modern machines equipped with advanced automation technology can drastically reduce manual labor, thereby minimizing human error and increasing production speed. Look for features such as programmable logic controllers (PLCs) that allow for precise control over the manufacturing process and real-time monitoring.

Another important factor to evaluate is the machine's versatility. The ability to switch between different pipe sizes and specifications without extensive downtime can dramatically enhance the productivity of the production line. Multi-function machines that accommodate various processes—such as forming, welding, and finishing—will offer a higher return on investment by maximizing output and reducing the need for multiple pieces of equipment. Additionally, consider the maintenance and support features built into the machines; easy access to parts and user-friendly interface can streamline operations and ensure long-term reliability.

Carbon steel pipes have become a fundamental component in manufacturing due to their robust characteristics and versatility. As industries, particularly oil and gas, are projected to expand significantly—forecasted to create a market opportunity of US$151 billion by 2032—the use of carbon steel pipes aligns perfectly with this growth. These pipes offer superior strength and durability, making them ideal for high-pressure applications. They also allow for efficient transportation of fluids, which is essential in various manufacturing processes.

Furthermore, the environmental benefits of using carbon steel pipes cannot be overlooked. With a focus on sustainability, the use of repurposed steel pipes supports a circular economy by minimizing the demand for new materials. This not only leads to substantial reductions in CO2 emissions—potentially as high as 97%—but also promotes responsible resource management in manufacturing. As companies strive to reduce their environmental footprint, integrating carbon steel pipes into production lines represents a smart and eco-friendly solution.

| Parameter | Value |

|---|---|

| Pipe Diameter Range | 1 inch to 12 inches |

| Production Speed | 50 meters per minute |

| Material Used | Carbon Steel |

| Typical Applications | Construction, Oil & Gas, Automotive |

| Corrosion Resistance | Moderate (with coatings) |

| Cost Efficiency | High |

| Weight | Heavy (material-dependent) |

| Weldability | Excellent |

Maintaining your carbon steel pipe making machines is crucial to ensure optimal performance and longevity. Regular inspections should form the backbone of your maintenance routine. Check for wear and tear on essential components such as rollers, welding heads, and forming dies. Identifying these issues early can prevent costly downtime and repairs. Additionally, maintaining proper lubrication throughout the machine helps reduce friction and wear, significantly extending the lifespan of the equipment.

Another best practice is to maintain a clean working environment around your machines. Dust and debris can accumulate and lead to mechanical failures or product contamination. Implementing a routine cleaning schedule, along with proper storage for both raw materials and finished products, will inhibit the buildup of unwanted materials around the machines. Additionally, consider utilizing vibration analysis and thermal imaging technologies. These advanced techniques can help detect potential malfunctions before they escalate, ensuring your production line remains efficient and effective.

Optimizing production lines in the pipe manufacturing industry is crucial for improving efficiency and reducing costs. According to a report by the International Pipe and Steel Products Association, implementing advanced carbon steel pipe making machines can enhance production speed by up to 25%, significantly impacting overall output. By investing in modern technologies, companies can reduce downtime and streamline their manufacturing processes, ensuring a smoother workflow and higher profitability.

One effective strategy for enhancing efficiency is the integration of automation in pipe production. A study from the Manufacturing Institute reveals that companies utilizing automated systems in their production lines can see a reduction in labor costs by approximately 20%. Additionally, automated inspection technologies can minimize defects and rework rates, as they ensure high precision and consistency throughout the production chain. By adopting these innovative solutions, manufacturers not only improve their production efficiency but also enhance their competitiveness in an increasingly demanding market.