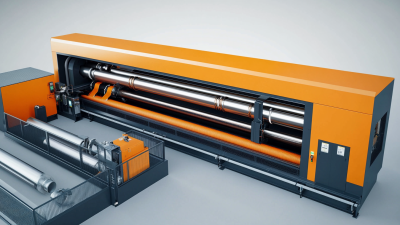

In today's manufacturing landscape, optimizing production efficiency is pivotal for the competitiveness of Pipe Making Machinery Tube Mill operations. According to a recent report by MarketsandMarkets, the global pipe and tube market is anticipated to grow at a compound annual growth rate (CAGR) of 3.7%, reaching USD 212.8 billion by 2027, underscoring the increasing demand for innovative machinery and efficient production processes. As companies strive to meet this demand, enhancing the productivity and performance of tube mills has become essential.

Implementing advanced technologies, improving operational workflows, and adhering to best practices in maintenance can significantly boost output while reducing costs. As the industry evolves, focusing on these optimization strategies within the pipe making sector not only supports sustainability but also positions manufacturers to capitalize on emerging opportunities in the marketplace.

In the realm of pipe making machinery, optimizing production efficiency hinges on accurately identifying key performance indicators (KPIs). These KPIs serve as crucial metrics, guiding manufacturers toward achieving operational excellence. By focusing on elements such as throughput, downtime, and machinery utilization rates, producers can derive actionable insights into their processes. For instance, adopting advanced data analytics can illuminate factors impacting efficiency, promoting informed decision-making that aligns with production goals.

Moreover, integrating machine learning and IoT technologies can significantly enhance monitoring capabilities. By analyzing real-time data, manufacturers can predict maintenance needs and identify inefficiencies before they escalate into costly disruptions. Notably, the synergy between predictive analytics and in-process monitoring strategies not only improves sustainability in manufacturing processes but also enriches the decision-making framework. This comprehensive approach ensures that pipe making machinery operates at peak efficiency, ultimately driving productivity and profitability in an increasingly competitive market.

In today’s competitive manufacturing environment, leveraging technology through automation solutions is key to enhancing efficiency in tube mills. Automated systems streamline operations by reducing manual interventions, minimizing errors, and optimizing production cycles. By implementing programmable logic controllers (PLCs) and real-time monitoring systems, manufacturers can gain insights into production performance, making it easier to identify bottlenecks and areas for improvement. This real-time data allows for quick adjustments, ultimately leading to more consistent product quality and reduced waste.

Additionally, advanced automation can facilitate predictive maintenance practices. By using sensors and IoT devices to continuously monitor equipment health, manufacturers can anticipate failures before they occur, reducing downtime and extending the lifespan of machinery. Integrating automation in the tube mill not only boosts productivity but also enables a more flexible production process that can adapt to varying demands. As the industry evolves, adopting automation solutions will be critical for manufacturers seeking to maintain a competitive edge and optimize their operational efficiency.

Regular maintenance practices play a pivotal role in maximizing production uptime for pipe making machinery, particularly in the context of tube mills. According to the Manufacturing Institute, unplanned downtime can cost manufacturers upwards of $50 billion annually, underscoring the importance of proactive maintenance strategies. Implementing a preventive maintenance schedule not only extends the lifespan of machinery but also reduces the likelihood of costly breakdowns. This approach ensures that equipment operates at peak efficiency, significantly enhancing overall productivity.

To achieve optimal performance in tube mills, it's essential to conduct routine inspections and timely repairs. This includes lubricating moving parts, checking alignment, and replacing worn-out components. Research from the National Institute of Standards and Technology indicates that regular maintenance can improve machine efficiency by as much as 15%.

**Tip:** Encourage technicians to utilize condition monitoring systems that track equipment health in real time, enabling quick responses to potential issues before they escalate. Furthermore, training staff on best maintenance practices can foster a culture of continuous improvement, leading to sustained operational excellence and reduced downtime.

| Maintenance Practice | Frequency | Impact on Uptime (%) | Cost of Maintenance ($) |

|---|---|---|---|

| Lubrication of Rolling Bearings | Weekly | 15 | 100 |

| Belt Tension Adjustment | Monthly | 10 | 75 |

| Inspection of Electrical Components | Quarterly | 20 | 150 |

| Replacement of worn-out Tools | Bi-Annually | 25 | 300 |

| Calibration of Machines | Yearly | 30 | 200 |

Training and skill development for operators are crucial elements in optimizing production efficiency in pipe-making machinery, particularly in tube mills. According to a report by the International Association of Tube and Pipe Manufacturers, businesses that invest in operator training see a 20% increase in productivity and a 25% reduction in machine downtime. This highlights the direct correlation between skilled operators and enhanced machine performance.

To maximize these benefits, companies should implement structured training programs that encompass both technical and soft skills. Providing operators with insights into machine operations, troubleshooting techniques, and maintenance procedures empowers them to perform their roles more effectively. For instance, adopting a mentorship system can facilitate knowledge transfer from experienced operators to newcomers, ensuring a steady skill development pipeline.

Tip: Regularly assess operator competencies and tailor training sessions to address specific skill gaps.

Furthermore, encouraging a culture of continuous learning can significantly contribute to employee morale and retention, which, according to a study by the Manufacturing Institute, can reduce turnover rates by 50%. This not only solidifies a company's skill base but also enhances overall operational efficiency in the long run.

Tip: Incorporate hands-on workshops and simulation exercises in training to improve practical skills.

In today's highly competitive manufacturing landscape, implementing data analytics in pipe-making machinery, particularly in tube mills, is essential for driving continuous improvement. According to a recent report by the International Institute of Tube and Pipe, manufacturers that utilize data-driven decision-making can boost operational efficiency by up to 25%. This is achieved by closely monitoring production metrics and identifying areas for optimization, such as reducing downtime and improving material yield.

Tip: Invest in a comprehensive data analytics platform that integrates seamlessly with your tube mill machinery. This allows for real-time monitoring and analysis of key performance indicators (KPIs), enabling swift corrective actions and enhancing productivity on the production floor.

Furthermore, leveraging predictive analytics can significantly reduce maintenance costs. A study from the Machinery Maintenance Association highlights that predictive maintenance can decrease unplanned downtime by 30%, resulting in substantial cost savings. By analyzing historical equipment data, manufacturers can foresee potential failures and schedule maintenance before issues escalate.

Tip: Regularly review and update your predictive maintenance algorithms to ensure they evolve with your production processes. Keeping your data models current will help you maintain optimal equipment performance and further boost production efficiency.