The manufacturing industry has seen significant advancements, particularly in the field of metal pipe production. A critical component of this evolution is the Ms Tube Mill Pipe Making Machinery, a technology that enhances efficiency and precision in pipe fabrication. According to industry expert Dr. James Carter, “The Ms Tube Mill Pipe Making Machinery revolutionizes how we produce high-quality tubing, ensuring consistency and strength in every piece.”

This machinery operates by transforming raw metal strips into durable pipes through a series of sophisticated processes. It utilizes a series of rollers and forming tools designed to shape the metal while maintaining tight tolerances. The importance of Ms Tube Mill Pipe Making Machinery cannot be overstated, as it serves a wide range of applications, from construction to automotive manufacturing.

In the following sections, we will delve deeper into the mechanisms of Ms Tube Mill Pipe Making Machinery, exploring its various components and the steps involved in the pipe-making process. Understanding this technology not only highlights its critical role in modern manufacturing but also sheds light on the broader impacts it has on the economy and industry standards.

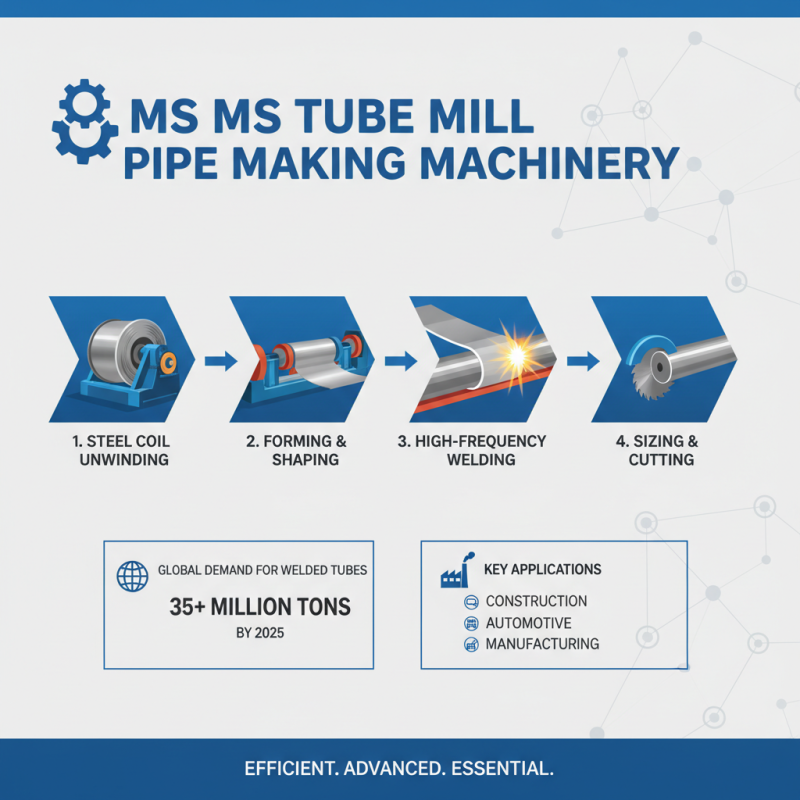

Ms Tube Mill Pipe Making Machinery is designed primarily for the production of tubes and pipes from steel strips or coils. This machinery employs a series of stages that transform flat metal sheets into cylindrical tubes, which can then be used in various applications, including construction, automotive, and manufacturing industries. The process typically involves the use of high-frequency welding to join the edges of the formed tube, ensuring structural integrity and enhancing the overall strength of the product. According to industry reports, the global demand for welded tubes is projected to reach over 35 million tons by 2025, highlighting the significance of efficient and advanced machinery in this sector.

The operation of Ms Tube Mill is geared towards optimizing productivity while maintaining precision and quality in the output. The machinery is equipped with features such as automatic feeding systems, advanced roller designs to shape the strips, and integrated cutting tools for length adjustments. Data from market analysis suggests that innovations in tube mill technology have improved efficiency rates by as much as 30%. This advancement not only supports higher production capacities but also reduces material wastage, making the process more cost-effective. Manufacturers utilizing modern Ms Tube Mill Pipe Making Machinery are thus better positioned to meet the increasing demands of various industries while adhering to strict quality standards.

The Ms Tube Mill is a sophisticated piece of machinery used for producing metal pipes with precision and efficiency. Its key components play vital roles in the tube-making process, ensuring high-quality output. One of the primary components is the entry section, which is crucial for aligning the raw material strips as they enter the mill. This section utilizes guides and rollers to position the strips correctly, preparing them for subsequent shaping.

Another essential component is the forming section, which consists of rollers that gradually shape the flat strips into cylindrical forms. The configuration of these rollers is meticulously designed to control the dimensions and tolerances of the final product. Additionally, the sizing section is critical for achieving the desired outer diameter of the pipes. Here, a set of sizing rollers applies pressure to fine-tune the pipe's dimensions while maintaining the necessary wall thickness. Together, these components work harmoniously to produce high-quality MS tubes for various applications in construction and manufacturing.

The manufacturing process of pipes using Ms Tube Mill involves several intricate steps that ensure precision and quality. Initially, the raw materials, typically flat steel strips, are prepared and guided through various rollers that shape them into a tubular form. This is known as the forming stage, where the edges of the steel strips are brought together to create a seam for welding.

Once the tube is formed, it undergoes a welding process, which is crucial for ensuring structural integrity. The edges of the tube are heated and fused together, typically using high-frequency welding techniques. This process is highly efficient and produces a strong bond. After welding, the tube is cooled and may be subjected to further processes such as sizing and cutting to meet the desired dimensions. The sizing operation ensures that the pipe has the correct diameter and wall thickness, which are essential for its intended application.

Finally, the finished pipes are subjected to quality control measures, including non-destructive testing methods, to check for any defects. Once approved, the pipes are prepared for packaging and shipment. The entire Ms Tube Mill pipe manufacturing process highlights the balance between technology and precision engineering, ensuring that the resulting pipes meet industry standards and customer requirements.

| Process Step | Description | Equipment Used | Material Used |

|---|---|---|---|

| Raw Material Preparation | Loading and cutting of steel coils to prepare for milling. | Coil Cutting Machine | Steel Coils |

| Forming | The steel strip is formed into a circular shape using rollers. | Roll Forming Machine | Steel Strip |

| Welding | Joining the edges of the formed strip through welding. | Welding Machine | N/A |

| Sizing | Sizing the welded pipe to ensure uniform diameter. | Sizing Machine | N/A |

| Finishing | Cleaning, inspecting, and cutting pipes to required lengths. | Cutting and Inspection Machines | N/A |

Ms Tube Mill Pipe products are widely adopted across various industries due to their versatility and strength. These pipes are commonly used in construction, automotive, and manufacturing sectors, where durability and performance are paramount. According to industry reports, the global demand for MS pipes is expected to grow by approximately 5% annually over the next five years, driven by increasing infrastructure projects and industrialization in emerging markets.

One significant application of Ms Tube Mill Pipe products is in structural applications, where they provide the necessary support for buildings and bridges. Their seamless construction minimizes the risk of leaks and fractures, which enhances safety and reduces maintenance costs. Additionally, these pipes are favored in the manufacture of consumer goods, providing a reliable option for furniture, appliances, and various mechanical components.

Tip: When selecting MS Tube Mill Pipes for your projects, always consider the specific requirements of the application, including environmental conditions and load capacities. Quality assurance during the manufacturing process is crucial to ensure longevity and performance. For projects involving heavy loads or complex installations, opting for pipes with higher yield strength can provide additional peace of mind.

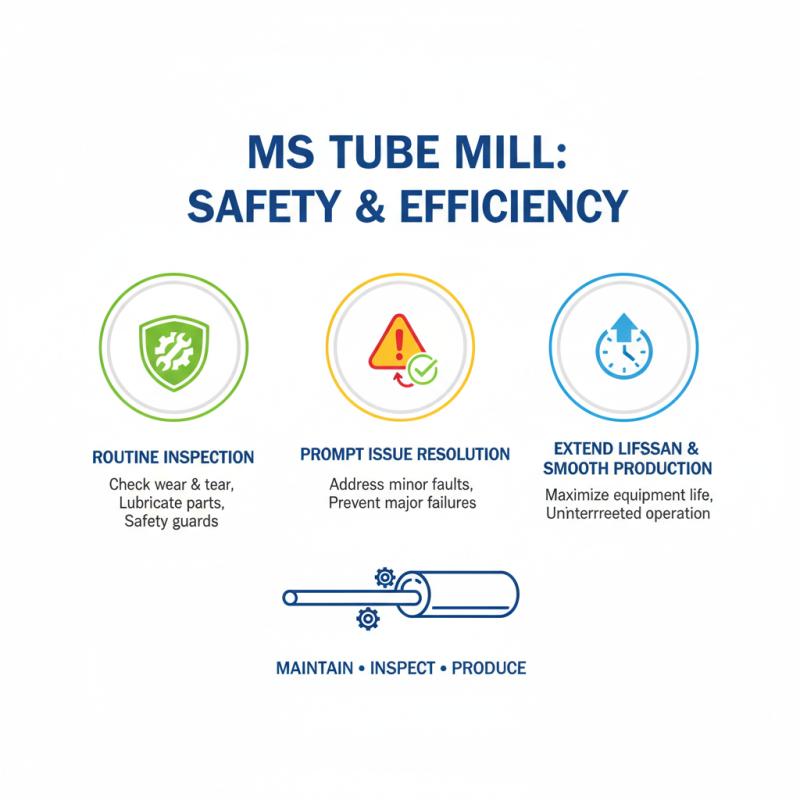

When operating Ms Tube Mill Pipe Making Machinery, maintaining safety and efficiency is paramount. Regular maintenance not only extends the lifespan of the equipment but also ensures that the production process runs smoothly. Operators should establish a routine inspection schedule that includes checking for wear and tear on key components, lubricating moving parts, and ensuring that all safety guards are in place. By addressing minor issues promptly, the risk of catastrophic failures can be significantly reduced.

In addition to routine inspections, it’s essential to implement best practices for safe operation. Ensure that all personnel are adequately trained in machine operation and safety protocols. Before starting the machinery, confirm that no unauthorized individuals are in the vicinity and that emergency shut-off switches are functioning properly. Regularly review and update safety procedures to reflect any changes in operation or machinery configuration.

Tips for operators include keeping the workspace tidy, ensuring proper ventilation, and wearing appropriate personal protective equipment (PPE) at all times. Using the machinery within its designated capacity and adhering to the manufacturer’s guidelines will help prevent accidents and injuries. By fostering a culture of safety and regular maintenance, operators can significantly improve both the productivity and safety of Ms Tube Mill operations.