In the rapidly evolving world of manufacturing, efficiency stands as a pivotal factor in determining success and competitiveness. The High Frequency Pipe Making Machine has emerged as a game-changer, revolutionizing the way pipes are produced across various industries. This tutorial delves into the nuances of maximizing operational efficiency while utilizing this advanced machinery. By comparing different methodologies, techniques, and maintenance practices, we aim to uncover the best strategies for optimizing performance and reducing production costs.

Whether you are a seasoned professional or a newcomer to the pipe manufacturing sector, understanding how to effectively harness the capabilities of the High Frequency Pipe Making Machine can significantly impact your productivity and bottom line. Join us as we explore innovative approaches and practical tips to elevate your machining processes to new heights.

In the rapidly evolving world of manufacturing, efficiency stands as a pivotal factor in determining success and competitiveness. The High Frequency Pipe Making Machine has emerged as a game-changer, revolutionizing the way pipes are produced across various industries. This tutorial delves into the nuances of maximizing operational efficiency while utilizing this advanced machinery. By comparing different methodologies, techniques, and maintenance practices, we aim to uncover the best strategies for optimizing performance and reducing production costs.

Whether you are a seasoned professional or a newcomer to the pipe manufacturing sector, understanding how to effectively harness the capabilities of the High Frequency Pipe Making Machine can significantly impact your productivity and bottom line. Join us as we explore innovative approaches and practical tips to elevate your machining processes to new heights.

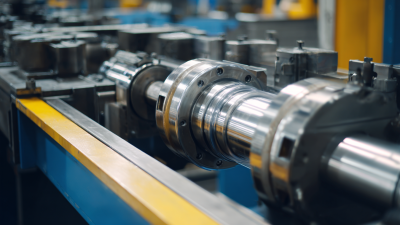

High frequency pipe making machines represent a significant advancement in manufacturing technology, enabling higher production rates and enhanced material utilization. These machines utilize high frequency induction welding techniques, which can produce seamless pipes at speeds up to 100 meters per minute. According to a report by Grand View Research, the global market for welded pipes is expected to reach $82 billion by 2025, highlighting the increasing demand for efficient production methodologies.

One of the standout features of these machines is their ability to produce pipes with varying diameters and thicknesses, catering to a wide range of applications in industries such as construction and oil & gas. With their precision engineering, high frequency pipe making machines ensure a consistent and high-quality weld, reducing waste and optimizing resource usage. A study conducted by the American Institute of Steel Construction indicates that adopting such advanced machinery can result in a 25% increase in productivity and a substantial decrease in manufacturing costs, making them an essential asset for modern pipe manufacturers looking to enhance efficiency.

| Feature | Description | Benefit |

|---|---|---|

| High Frequency Welding Technology | Utilizes high-frequency electric currents to weld metal sheets together. | Produces strong, durable welds while minimizing heat effects on the material. |

| Automated Control Systems | Incorporates programmable logic controllers (PLCs) for seamless operation. | Enhances precision and reduces the likelihood of human error in the production process. |

| Versatile Pipe Sizes | Capable of producing a wide range of pipe diameters and thicknesses. | Allows manufacturers to cater to diverse customer requirements more effectively. |

| Energy Efficiency | Designed to minimize energy consumption during the manufacturing process. | Reduces operational costs and supports sustainability initiatives. |

| User-Friendly Interface | Features intuitive controls for ease of use by operators. | Facilitates quick training of staff, leading to higher productivity levels. |

Setting up and calibrating your high frequency pipe making machine is crucial for achieving optimal performance in pipe production. Begin by ensuring that all components of the machine are clean and properly aligned. A well-maintained machine minimizes downtime and maximizes output. Pay close attention to the alignment of the welding head and the feeder mechanism, as even slight misalignments can lead to defects in the final product.

Tip: Regularly inspect and clean the machine's rollers and guides to prevent any obstructions that may disrupt the flow of materials. This not only prolongs the lifespan of the machine but also helps maintain consistent product quality.

Calibration is equally important. Use precise measurement tools to adjust the machine settings according to the specifications of the materials you are processing. Monitor temperature settings, as optimal heat control is imperative for seamless welding.

Tip: Implement a routine calibration schedule to ensure that all parameters remain within the recommended ranges. Document these calibrations for future reference, as this can help you quickly resolve any unexpected production issues.

Maximizing production speed and output efficiency is crucial for manufacturers utilizing high-frequency pipe making machines. One effective technique to enhance production speed is optimizing the machine's operational parameters. By fine-tuning settings such as welding speed, frequency, and temperature, manufacturers can minimize downtime and ensure seamless transitions during the production process. Regular maintenance checks also play a vital role in maintaining optimal performance, as well-functioning equipment can lead to significantly faster production cycles.

Another strategy involves the integration of automation and advanced technology. Employing automated systems for material handling and quality inspection allows for continuous operation, reducing the time workers spend on manual tasks. Implementing sophisticated control software can also provide real-time data analytics, enabling operators to swiftly identify and rectify bottlenecks in the production line. By adopting these techniques, manufacturers can substantially increase their output efficiency while maintaining the quality of the pipes produced, ultimately leading to improved profitability.

When operating a high frequency pipe making machine, encountering issues is almost inevitable. One common problem is inconsistent weld quality, which can lead to weak joints and compromised product integrity. To troubleshoot this, ensure that the machine is properly calibrated and that the materials are clean and free from contaminants. Regular inspection of the welding electrodes is essential, as worn electrodes can contribute to poor welding results.

Another typical issue is overheating in the machine components. Overheating can not only damage the equipment but also affect the quality of the produced pipes. To combat this, maintain a regular cooling schedule and check coolant levels frequently. Incorporating temperature sensors can provide real-time monitoring and alert operators before any potential overheating occurs.

Lastly, feed rate inconsistencies may arise during production, causing variability in pipe dimensions. Operators should monitor the feed mechanism for any blockages or mechanical failures. It’s also beneficial to train staff on the nuances of the machine, so they can quickly identify and adjust parameters for optimal performance. Regular maintenance and attention to detail will not only enhance efficiency but also extend the lifespan of the machinery.

As the pipe manufacturing industry evolves, future innovations and trends are set to reshape how we approach pipe production. One significant trend is the integration of automation and smart technology. According to a report by MarketsandMarkets, the global pipe manufacturing market is projected to reach $236 billion by 2025, driven largely by advancements in automation that enhance production efficiency. High-frequency pipe making machines equipped with real-time monitoring technology can optimize manufacturing processes, reduce waste, and minimize downtime, setting a new standard for operational efficiency.

Another notable trend is the increasing emphasis on sustainability. The industry is witnessing a push towards eco-friendly materials and manufacturing processes, in line with growing environmental regulations. Research from the International Energy Agency indicates that the manufacturing sector accounts for approximately 36% of global energy consumption, highlighting the need for innovations that reduce energy use and carbon footprint. Techniques such as automated recycling systems for pipe production not only capitalize on raw material efficiency but also align with global sustainability goals, ensuring that the pipe manufacturing sector remains competitive and responsible in a rapidly changing market.