In the ever-evolving landscape of manufacturing, the Tube Mill Pipe Making Machine stands out as a pivotal technology in the production of high-quality pipes and tubes. According to a report by Market Research Future, the global market for tube and pipe manufacturing machinery is projected to reach USD 6.5 billion by 2025, driven by increasing demand in construction, automotive, and energy sectors. This growth underscores the essential role of efficient tube mill processes in meeting stringent industry standards. As manufacturers strive for innovation, mastering the art of tube mill pipe making not only enhances operational efficiency but also minimizes waste and maximizes output quality. In this comprehensive tutorial, we will delve into the intricacies of tube mill pipe making machines, exploring the latest advancements that propel productivity while ensuring sustainable practices in the manufacturing process.

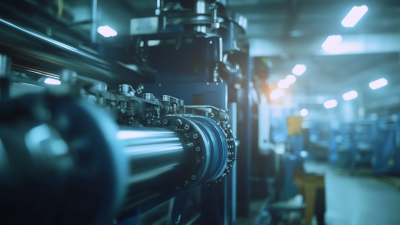

Understanding Tube Mill Pipe Making Machines requires a thorough exploration of their operation and efficiency. These machines are pivotal in the manufacturing industry, enabling the production of pipes and tubes of varying sizes and specifications. A typical tube mill consists of several components, including the uncoiler, accumulator, forming section, and welding section. Each part plays a significant role in the overall process, from feeding raw materials to shaping and welding them into finished products.

To enhance efficiency when using tube mill machines, consider implementing regular maintenance schedules. Keeping all components in optimal condition minimizes downtime and maximizes production output. Additionally, training operators in the latest technologies and techniques can significantly improve workflow. Always monitor the machine settings and make necessary adjustments to maintain the balance between speed and quality; this will ensure high standards in every batch produced.

Another important tip is to invest in quality raw materials. The choice of steel or other materials affects not only the strength of the final product but also affects the machine's operating conditions. By selecting superior materials and employing advanced technologies, manufacturers can achieve innovation in their tube mill processes, leading to greater competitiveness in the market.

In the competitive world of pipe production, innovative technologies play a crucial role in enhancing efficiency and improving overall output. One of the most significant advancements in tube mill pipe making machines is the integration of automation and smart technology. Automated systems can streamline the manufacturing process, reducing labor costs while increasing precision. These machines can adjust operational parameters in real-time, ensuring high-quality product consistency and minimizing waste. By implementing such technologies, manufacturers can better meet market demands and improve their profit margins.

Another key area of innovation is the use of advanced materials and design techniques in the production of tube mill machinery. High-strength alloys and innovative coating technologies can enhance the durability and longevity of the machines, reducing downtime and maintenance costs. Furthermore, the incorporation of data analytics in monitoring equipment performance facilitates predictive maintenance, thus preventing unexpected failures. This proactive approach to machine upkeep not only ensures uninterrupted production but also extends the lifespan of the equipment, driving significant cost savings over time. Embracing these cutting-edge solutions is essential for manufacturers aiming to thrive in the ever-evolving landscape of pipe production.

In modern manufacturing, the evolution of tube mill design is imperative for companies seeking efficiency and innovation. Traditional tube mills often struggle with limitations in material versatility and production speed. However, recent advances in composite materials, as detailed in multiple comprehensive reviews, highlight a shift towards lighter and stronger alternatives. These innovations pave the way for new tube mill designs that emphasize not just performance but sustainability, catering to industries like automotive manufacturing, where lightweight structures are crucial for enhancing fuel efficiency.

**Tip:** When considering alternatives to traditional tube mills, explore designs that integrate advanced composite technologies. This can reduce overall weight and improve the mechanical properties of the products you manufacture, ultimately leading to increased market competitiveness.

Furthermore, the integration of advanced manufacturing technologies allows for the miniaturization of components, as noted in ongoing research across various sectors. Innovations in drift tube ion mobility spectrometry, for example, exemplify how modern manufacturing techniques can lead to more efficient and precise production methods. This paradigm shift is essential for manufacturers aiming to remain relevant in a rapidly changing market.

**Tip:** Stay informed on recent technological developments and consider investing in training for your team. Adapting to these advancements will allow your business to leverage new manufacturing processes and improve overall production effectiveness.

| Dimension | Value | Notes |

|---|---|---|

| Pipe Diameter Range | 1" - 12" | Standard range for tube mills |

| Production Speed | Up to 120 meters/min | Speed depending on material and size |

| Material Types | Steel, Aluminum, Stainless Steel | Common materials for pipe production |

| Energy Consumption | 75-150 kW | Varies by machine type and configuration |

| Maintenance Frequency | Monthly | Regular checks to ensure optimal performance |

| Waste Reduction Technology | In-line Virtual Laser Measurement | Minimizes scrap during production |

| Automation Level | Fully Automated | Increased efficiency and reduced labor costs |

In the evolving landscape of manufacturing, tube mill equipment has become pivotal in driving cost-effectiveness. According to a report by MarketsandMarkets, the global tube and pipe market is projected to reach $151.5 billion by 2025, highlighting a growing emphasis on efficiency. Manufacturers are increasingly seeking out advanced tube mill pipe making machines that not only optimize production but also reduce operational costs. This comparative analysis delves into the features and benefits of various tube mill systems, emphasizing the importance of selecting machines that offer superior technology for streamlined operations.

One of the standout advancements in tube mill technology is the transition to fully automated systems. A study published by Grand View Research indicates that automation can reduce labor costs by up to 30%, in addition to minimizing production time. By investing in high-efficiency tube mill equipment with smart features such as real-time monitoring and predictive maintenance, manufacturers can achieve significant savings. Furthermore, the ability to produce high-quality pipes with consistent thickness and finish can lead to reduced wastage, further enhancing the cost-effectiveness of tube mill operations. This strategic approach not only boosts profitability but also positions companies favorably in a competitive market.

In the fast-evolving landscape of manufacturing, optimizing production for tube mill pipe making machines has become essential for maintaining a competitive edge. According to a report by MarketsandMarkets, the global pipe and tube manufacturing market is expected to grow to $150 billion by 2025, driven by increasing demand across various industries. To meet this demand efficiently, operators must implement best practices in both machine operation and maintenance.

One of the critical aspects of optimizing production is regular maintenance schedules. A study published by the American Society of Mechanical Engineers found that companies that adhere to a proactive maintenance strategy experience a 25% reduction in downtime. Incorporating predictive maintenance technologies, such as vibration analysis and thermal imaging, not only extends the lifespan of the machines but also enhances overall productivity. Additionally, providing comprehensive training for operators ensures that they can skillfully manage the machinery, leading to improved quality control and minimized waste.

Furthermore, leveraging innovations in automation can significantly boost efficiency. According to a report from Deloitte, facilities that have adopted advanced manufacturing technologies see productivity improvements of up to 30%. Implementing smart sensors and real-time monitoring systems can facilitate data-driven decision-making, ultimately streamlining processes and reducing production costs. By focusing on these best practices, manufacturers can position themselves to thrive in an increasingly competitive market.