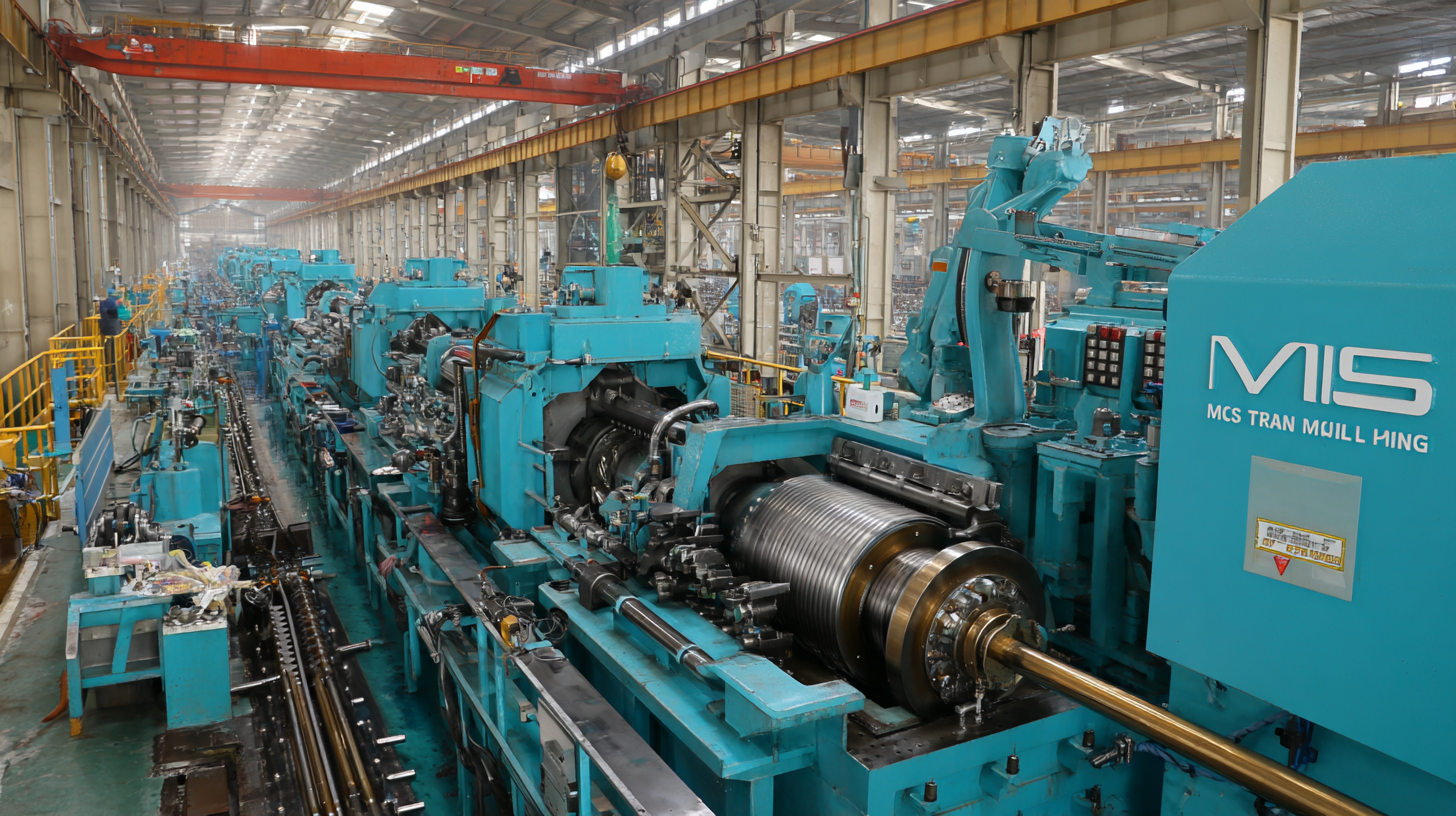

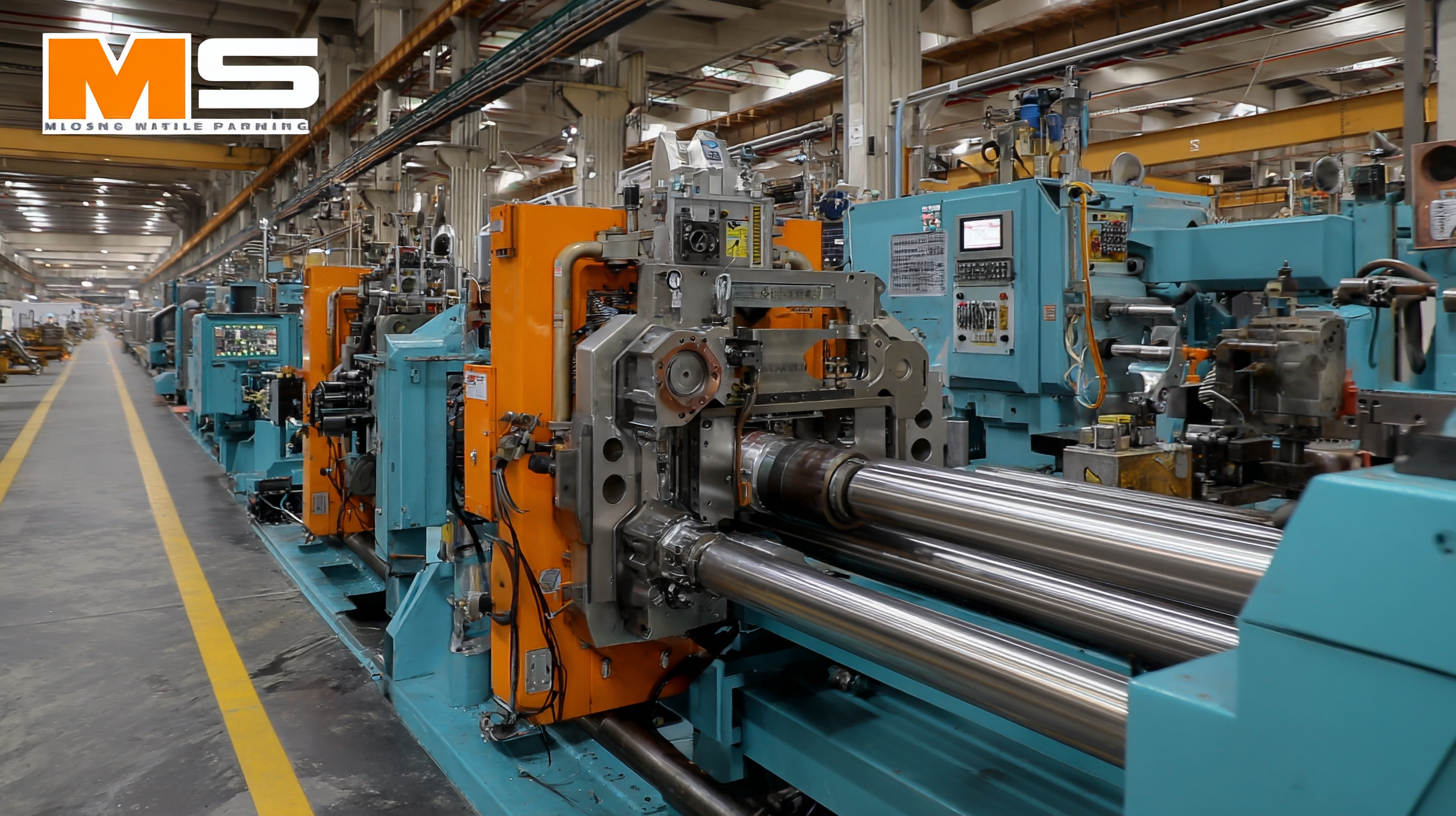

In the world of manufacturing, the efficiency and precision of production equipment is paramount, especially when it comes to the fabrication of pipes and tubes. Among the various types of equipment, Ms Tube Mill Pipe Making Machinery stands out for its capability to produce high-quality metal pipes with optimal performance. This blog aims to explore the leading global manufacturers of Ms Tube Mill Pipe Making Machinery, delving into their advanced technologies, innovative designs, and the key features that set them apart in an increasingly competitive market. As industries continue to evolve and demand for durable, reliable piping solutions rises, understanding the landscape of these manufacturers and the machinery they offer becomes essential for businesses looking to enhance their production capabilities. Join us as we navigate through this vital sector, uncovering insights that can guide informed decisions for manufacturers and engineers alike.

Innovative technologies are rapidly transforming the MS tube mill market, pushing the boundaries of efficiency and production capabilities. By 2025, we can expect to see significant advancements in automation and digitalization within manufacturing processes.

Smart factories equipped with IoT devices are set to optimize every stage, from raw material handling to quality control. This integration not only minimizes human error but also maximizes throughput and productivity.

Furthermore, eco-friendly innovations are gaining traction, driven by the global push for sustainability. Manufacturers are beginning to adopt energy-efficient machinery and explore the use of alternative materials that reduce environmental impact. These green technologies not only comply with regulatory standards but also appeal to environmentally conscious consumers and businesses looking to enhance their corporate social responsibility profiles. As the MS tube mill market evolves, embracing these innovative solutions will be crucial for manufacturers aiming to maintain a competitive edge.

The manufacturing of MS (mild steel) tubes has evolved significantly over the years, driven by advancements in technology and increasing demand across various industries. Leading manufacturers are at the forefront of this evolution, providing sophisticated tube mill and pipe-making equipment that enhances efficiency and quality. Key players in this sector include renowned companies that specialize in innovative design and engineering, ensuring their products meet the highest industry standards. Their commitment to research and development allows them to introduce cutting-edge solutions that cater to the specific needs of clients, driving growth in the MS pipe making equipment market.

Furthermore, these industry leaders understand the crucial role of automation and smart technologies in modern manufacturing processes. By integrating automation solutions into their equipment, they not only boost productivity but also minimize operational costs. As the demand for MS pipes surges in construction, automotive, and infrastructure projects, these manufacturers are strategically positioned to capitalize on market opportunities. Their investment in sustainable practices and energy-efficient machinery also reflects a growing trend towards environmentally responsible manufacturing, making them key players in the global landscape of MS tube mill production.

The market for MS tube mill manufacturers is experiencing significant trends and challenges that shape its future landscape. One prominent trend is the increasing demand for lightweight and high-strength materials in various industries, which pushes manufacturers to innovate. Companies are focusing on developing advanced tube mill technology that can cater to these requirements while increasing production efficiency. This shift not only enhances product quality but also reduces operational costs, allowing manufacturers to remain competitive amidst growing market pressures.

However, manufacturers face challenges such as fluctuating raw material prices and the need for substantial capital investment in modern machinery. To navigate these hurdles, companies should consider implementing lean manufacturing principles. By optimizing processes and reducing waste, they can improve profitability and adaptability in a volatile market. Additionally, investing in employee training ensures that the workforce is skilled in operating new technologies and meeting evolving customer demands.

As manufacturers look to expand their global market presence, understanding regional market dynamics becomes crucial. Tailoring products to meet specific regulatory standards and consumer preferences can provide a competitive edge. Regular market research and collaboration with local partners can further facilitate a smoother entry into new markets, ensuring sustained growth and success in the ever-evolving tube mill industry.

| Manufacturer Region | Annual Production Capacity (Tons) | Market Share (%) | Key Technologies Used | Challenges Faced |

|---|---|---|---|---|

| North America | 150,000 | 25 | High-frequency Welding | Supply Chain Disruptions |

| Europe | 200,000 | 30 | Laser Cutting Technology | Rising Raw Material Costs |

| Asia-Pacific | 350,000 | 35 | Advanced Automation | Environmental Regulations |

| Latin America | 80,000 | 15 | Automated Pipe Inspection | Technological Adoption |

| Middle East & Africa | 50,000 | 5 | Cold Forming Technology | Political Instability |

The MS pipe manufacturing sector is increasingly prioritizing sustainability, recognizing its critical role in mitigating environmental impacts. Leading manufacturers are adopting energy-efficient methods and sourcing raw materials responsibly to reduce their carbon footprint. By investing in modern technologies, such as advanced electric arc furnaces and innovative tube mill equipment, these companies not only enhance productivity but also significantly decrease energy consumption and emissions during the production process.

Moreover, many manufacturers are implementing closed-loop water systems to minimize water waste and reusing by-products in their operations. The introduction of eco-friendly coatings and treatments also contributes to reduced environmental harm while maintaining product quality. As industry leaders continue to explore sustainable practices, the integration of these strategies not only supports regulatory compliance but also caters to the growing consumer demand for environmentally responsible products.

By fostering a culture of sustainability, the MS pipe manufacturing sector is positioning itself as a key player in the global shift towards greener industrial practices.

The demand for MS tube mills is on the rise, driven by the expanding applications across diverse industries. As manufacturers continue to innovate, MS tube mills are integrating advanced technologies that enhance efficiency and product quality. This evolution opens up a plethora of opportunities for industries such as construction, automotive, and infrastructure, where the need for durable and high-quality metal pipes is crucial. The growing focus on sustainability also encourages manufacturers to utilize eco-friendly materials, aligning MS tube production with global environmental standards.

Moreover, the future of MS tube mills is bright as new markets emerge. The energy sector, particularly in renewable energy applications, is increasingly relying on strong and lightweight tube solutions for wind turbines and solar panel frameworks. Additionally, advancements in customization allow manufacturers to meet specific client requirements, further broadening the scope of MS tube applications. As industries continue to embrace innovative technologies, the versatility of MS tube mills will place them at the forefront of manufacturing processes worldwide, driving both growth and innovation in the years to come.