In today's highly competitive manufacturing landscape, the significance of investing in High Quality Pipe Machine Equipment cannot be overstated. According to the latest industry reports, companies that prioritize advanced machinery can enhance production efficiency by up to 30%, significantly reducing operational costs and downtime. Furthermore, a survey by the Association for Manufacturing Technology indicates that 72% of manufacturers believe that upgrading to high-quality machines is crucial for staying ahead of market demands.

These investments not only facilitate the production of superior quality pipes but also ensure compliance with stringent industry standards, ultimately leading to increased customer satisfaction and loyalty. As production lines evolve, the choice of equipment will play a pivotal role in determining a company’s success; thus, understanding the multifaceted benefits of high-quality machinery is essential for any forward-thinking manufacturer.

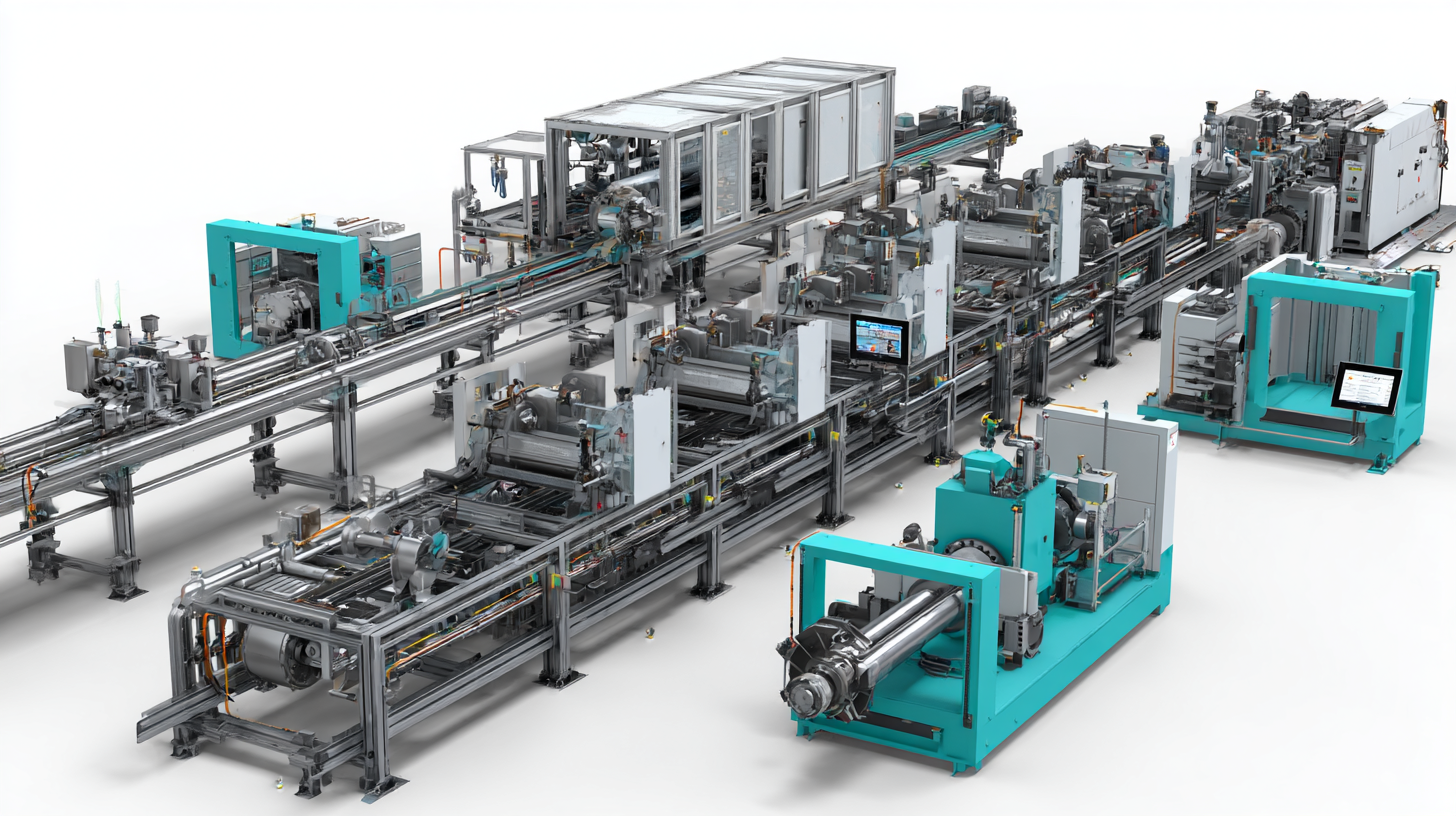

High-quality pipe machine equipment plays a pivotal role in enhancing the efficiency of production processes across various industries. According to a report published by MarketsandMarkets, the global pipe manufacturing equipment market is projected to grow significantly, reaching an estimated value of $1.2 billion by 2025. Investing in top-tier machinery not only increases production speed but also improves the precision of manufactured pipes, leading to reduced material waste and lower operational costs. This efficiency boost is particularly critical in sectors like construction and automotive, where precision and speed can directly impact project timelines and budgets.

Moreover, advanced pipe machines now come equipped with smart technology features that allow for real-time monitoring and automation of the production line. This adaptation is crucial as enterprises strive to adhere to Industry 4.0 principles, which emphasize automation and data exchange. A study by McKinsey & Company suggests that companies implementing such smart technologies can achieve productivity increases of 20-30%. Thus, investing in high-quality pipe machinery is not merely an upgrade; it's a strategic move that enhances production efficiency while aligning with modern manufacturing practices.

Investing in high-quality pipe machine equipment can lead to significant cost savings over time for any production line. While the initial outlay may seem substantial, the durability and efficiency of premium machines reduce the frequency of repairs and replacements, leading to lower maintenance costs in the long run. These machines are often designed with advanced technology that minimizes waste and maximizes output, resulting in a more streamlined production process.

Moreover, high-quality equipment typically operates at greater efficiency, which can translate into lower energy consumption. This not only helps in reducing utility costs but also contributes to a more sustainable production approach. As businesses face increasing scrutiny over their environmental footprint, having energy-efficient machinery can enhance a company's reputation while providing tangible financial advantages.

The long-term financial benefits of investing in superior pipe machinery are clear: reduced operating costs, enhanced reliability, and the potential for increased profitability, making it a smart choice for manufacturers looking to optimize their production lines.

In today's competitive manufacturing landscape, the quality of products produced greatly hinges on the machinery employed in the production line. Precision engineering plays a pivotal role in enhancing product quality, particularly when it comes to high-quality pipe machine equipment. These machines are designed to deliver impressive accuracy, minimizing production errors and ensuring consistency across every output. By investing in advanced machinery, manufacturers can achieve tighter tolerances and superior finishes, which are essential for industries that demand high standards, such as automotive and aerospace.

Moreover, the impact of precision engineering extends beyond mere product output. It fosters a streamlined production process by reducing waste and rework, leading to greater efficiency and cost-effectiveness. High-quality pipe machines not only maintain exact specifications but also adapt to different materials and designs with ease, further enhancing the overall production capabilities. As a result, companies that prioritize precision engineering in their machinery stand to benefit not only from improved product quality but also from increased customer satisfaction and a stronger competitive edge in the market.

Investing in high quality pipe machine equipment is crucial for maintaining a seamless production line. One of the paramount benefits is the significant reduction in downtime. According to a report by the Machinery Maintenance Association, businesses can lose up to 20% in productivity due to machine failures and unplanned maintenance. Reliable machinery ensures that operations run continuously, minimizing interruptions and enhancing overall efficiency. High quality machines not only reduce the chances of malfunction but also come with better support and longer operational lifespans.

To optimize the performance of your production line, consider implementing a regular maintenance schedule for your equipment. This proactive approach can help identify potential issues before they escalate, thus ensuring uninterrupted production. Additionally, training your staff on the proper usage and handling of machinery can further reduce the risk of operational errors that lead to downtime. Remember, investing in quality equipment is not merely a cost but a strategic move that pays dividends in increased productivity and reliability.

Investing in high-quality pipe machine equipment is not just about improving production efficiency; it’s about embracing technological advancements that give your business a competitive edge. With the rapid evolution of manufacturing technologies, integrating the latest innovations in your production line can significantly enhance productivity and product quality. Advanced pipe machines often come equipped with smart technologies such as automation, real-time monitoring, and predictive maintenance features, allowing manufacturers to streamline operations and reduce downtimes.

Tips: When considering an upgrade, evaluate equipment that offers connectivity features to enable data collection and analytics. This can help in making informed decisions about production processes and maintenance schedules, ultimately saving costs and improving output.

Moreover, high-quality machinery often includes cutting-edge design features that enhance operational precision. Utilizing equipment that supports advanced production techniques, like additive manufacturing or CNC (Computer Numerical Control), can elevate product consistency and reduce waste.

Tips: Ensure your workforce is adequately trained to operate new technologies efficiently. Investing in upskilling your team can maximize the benefits of advanced machinery, fostering a culture of innovation that aligns with your company's growth objectives.