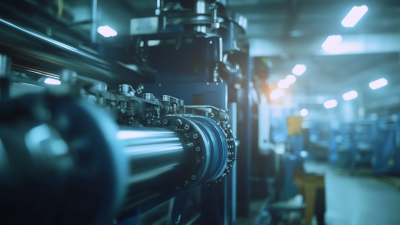

Investing in a High Frequency Tube Mill Making Machine can significantly enhance the efficiency and productivity of your manufacturing business. In an increasingly competitive market, businesses must leverage advanced technologies to stay ahead. A High Frequency Tube Mill offers various advantages, including faster production times, superior product quality, and the ability to work with a diverse range of materials. This investment not only optimizes operational processes but also contributes to long-term profitability through reduced production costs and waste.

As industries evolve, the demand for high-quality tubing continues to rise, making it imperative for manufacturers to adopt cutting-edge machinery. The High Frequency Tube Mill Making Machine stands out due to its innovative design, which allows for seamless and high-speed production of tubes. By focusing on the benefits of this technology, businesses can tap into new markets and meet the growing expectations of their clients. Moreover, understanding the top reasons to integrate this machinery can guide decision-makers in making informed investments that ensure sustained growth and competitive advantage in their respective fields.

Investing in a high frequency tube mill making machine can significantly enhance the production efficiency of any manufacturing business. These machines are designed to offer rapid processing speeds, allowing for higher output compared to traditional tube mills. By utilizing advanced technology, high frequency tube mills minimize downtime and streamline the production workflow, resulting in substantial time savings and the ability to meet increased demand without compromising on quality.

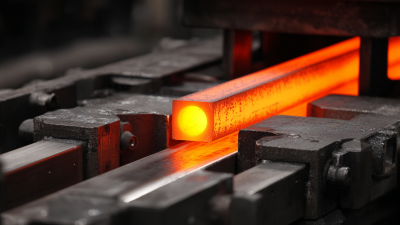

Furthermore, the precision and consistency of products produced by high frequency tube mills are unmatched. These machines employ high-frequency welding, which not only strengthens the seams but also reduces the risk of defects. This leads to less waste and lower material costs, as manufacturers can confidently produce uniform tubes that meet stringent quality standards. Ultimately, the investment in a high frequency tube mill not only boosts overall production efficiency but also enhances the competitiveness of a business in a rapidly evolving market.

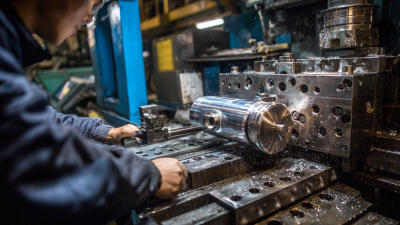

Investing in a high frequency tube mill making machine can significantly enhance the cost-effectiveness of your business over time. Unlike traditional tube-making methods that often involve extensive manual labor and longer production cycles, high frequency tube mills streamline the manufacturing process. This efficiency translates into reduced operational costs, as the machines require less energy and labor input to produce high-quality tubes quickly and consistently.

Furthermore, the durability and reliability of high frequency tube mill machines contribute to long-term savings. These machines are designed for high-volume production and can withstand the rigors of continuous operation, minimizing downtime and maintenance expenses. The precision engineering involved in these mills also leads to lower material waste, ensuring that you maximize the value of every resource used in production. By investing in a high frequency tube mill, businesses not only improve their production capabilities but also realize significant financial benefits over the life of the equipment.

| Feature | Traditional Mill | High Frequency Tube Mill | Savings (%) |

|---|---|---|---|

| Initial Investment | $200,000 | $150,000 | 25% |

| Energy Consumption (kWh/year) | 30,000 | 15,000 | 50% |

| Maintenance Cost (per year) | $25,000 | $10,000 | 60% |

| Production Speed (meters/min) | 20 | 40 | 100% |

| Life Span (years) | 10 | 15 | 50% |

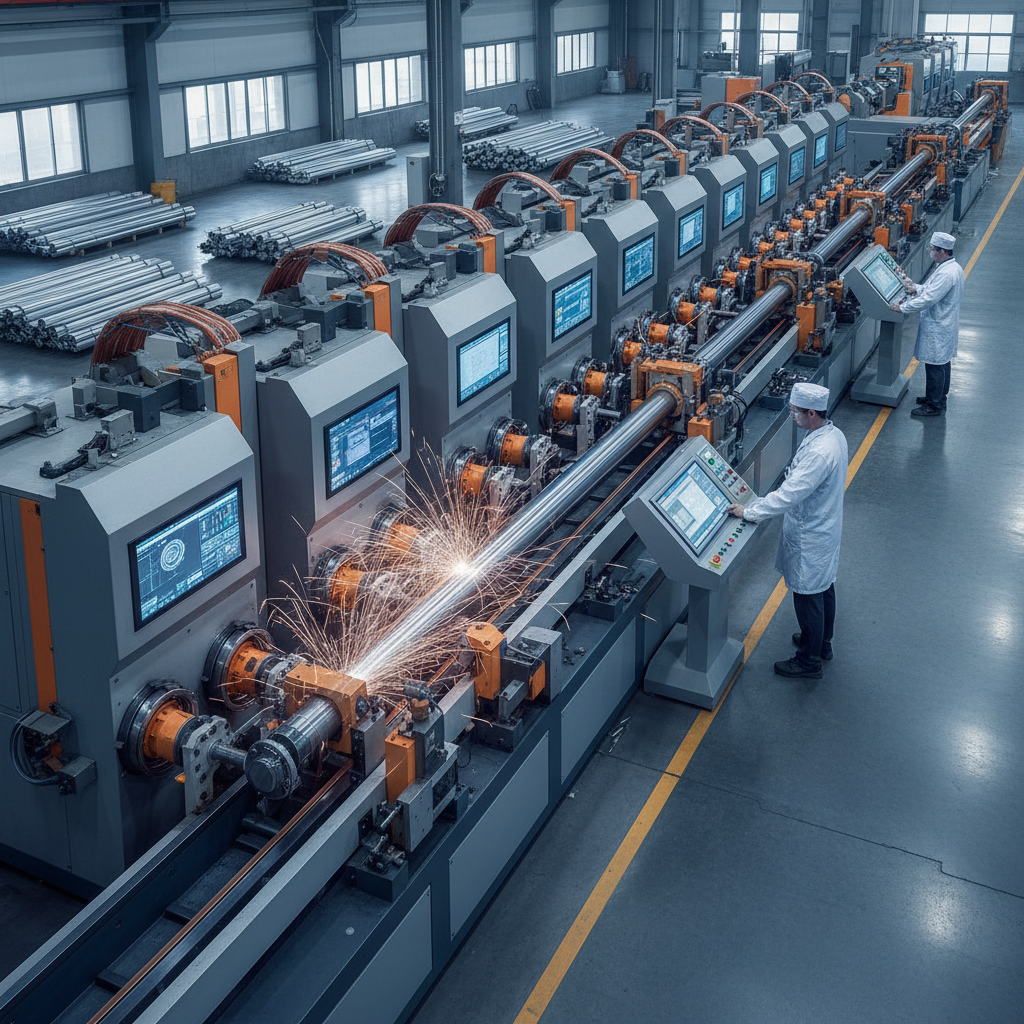

High-frequency tube mills have emerged as a vital asset across various industries due to their versatility in application. These machines are capable of producing tubes and pipes made of different materials, which makes them indispensable in sectors such as construction, automotive, and aerospace. Their ability to handle a wide range of specifications allows businesses to cater to diverse customer needs, enhancing production efficiency while minimizing waste.

To maximize the benefits of investing in a high-frequency tube mill, here are some tips: Firstly, consider the machine's adaptability. Ensure that it can accommodate future changes in production demands or materials. Secondly, invest in proper training for your staff. Well-trained operators can optimize machine performance, leading to higher outputs and reduced downtime. Finally, regularly maintain your equipment to prevent costly repairs and ensure consistent quality in production.

The flexibility of high-frequency tube mills also extends to their production capabilities. They can manufacture products in various sizes and shapes, making them suitable for applications beyond traditional tubing. Industries such as energy, where specialized pipes are required, and food processing, which demands sanitary tubing, have greatly benefited from the advancements in tube mill technology. This adaptability not only drives innovation but also keeps businesses competitive in a rapidly evolving market.

High frequency tube mills are revolutionizing the manufacturing landscape by significantly enhancing product quality. According to a recent study by the Tube & Pipe Manufacturers Association, companies utilizing these advanced machines have reported a 30% increase in consistency and finish quality of their products. This is crucial in industries such as automotive and construction, where precision and reliability are paramount. High frequency welding technology ensures that seams are stronger and smoother, which not only enhances the aesthetic appeal but also maximizes the structural integrity of the tubes produced.

Moreover, the operational efficiency of high frequency tube mills plays a vital role in improving output. A report by MarketsandMarkets reveals that manufacturers who switch to high frequency processes can achieve production speeds up to 40% faster compared to conventional methods. This increase in efficiency not only boosts overall production but also reduces waste and downtime. By investing in high frequency tube mill making machines, businesses can not only elevate their product quality but also streamline their operations, positioning themselves as leaders in a highly competitive market.

In today’s rapidly evolving industrial landscape, investing in a high-frequency tube mill making machine is not just a choice but a strategic necessity. The role of technology in tube manufacturing has become paramount as businesses strive to enhance efficiency, product quality, and overall competitiveness. Advanced machines equipped with high-frequency welding technology can significantly reduce production time while increasing precision, ensuring that companies can meet the growing demands of their customers without compromising on quality.

Future-proofing your business involves adopting innovations that align with market trends and consumer expectations. High-frequency tube mills not only offer better operational efficiencies but also provide the flexibility to produce a variety of tube sizes and specifications. This adaptability is vital in an era where customization is key. By utilizing state-of-the-art technology, manufacturers can respond swiftly to changes in the market, allowing them to maintain a competitive edge and secure their position in the forefront of the industry.