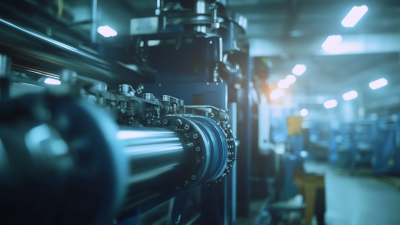

The demand for precision and durability in industrial applications has led to significant advancements in the machinery used for manufacturing steel pipes and tubes. High Quality Steel Pipe Machines and Tube Mills are at the forefront of this evolution, incorporating innovative techniques that enhance production efficiency and material quality. According to a report by Smithers Pira, the global market for steel pipes is projected to reach $102 billion by 2025, highlighting the critical role that advanced manufacturing technologies play in meeting this rising demand. Furthermore, new developments in automation and smart manufacturing are shaping the future of tube mills, allowing for real-time monitoring and control of production processes, which minimizes waste and maximizes productivity. As industries strive for sustainability and competitiveness, the integration of high-performance machinery such as High Quality Steel Pipe Machines Tube Mill is essential for achieving operational excellence and delivering high-quality products to the market.

In recent years, the steel pipe manufacturing industry has witnessed a significant transformation driven by innovative automation techniques. The integration of advanced robotics and artificial intelligence has enhanced production efficiency, leading to a reported increase in output by up to 25%, as highlighted in the latest report by Global Market Insights. Automation not only streamlines processes but also minimizes human error, ensuring that quality standards are consistently met.

Moreover, real-time monitoring systems have become a game changer in maintaining product integrity. According to a study by the International Journal of Advanced Manufacturing Technology, factories that have implemented smart sensors and IoT technologies have seen a reduction in defect rates by approximately 30%. This enhanced quality control allows manufacturers to quickly identify and address potential issues, fostering an environment of continuous improvement.

As industries evolve, the adoption of these innovative automation techniques becomes essential for maintaining competitiveness and meeting the ever-increasing demand for high-quality steel products.

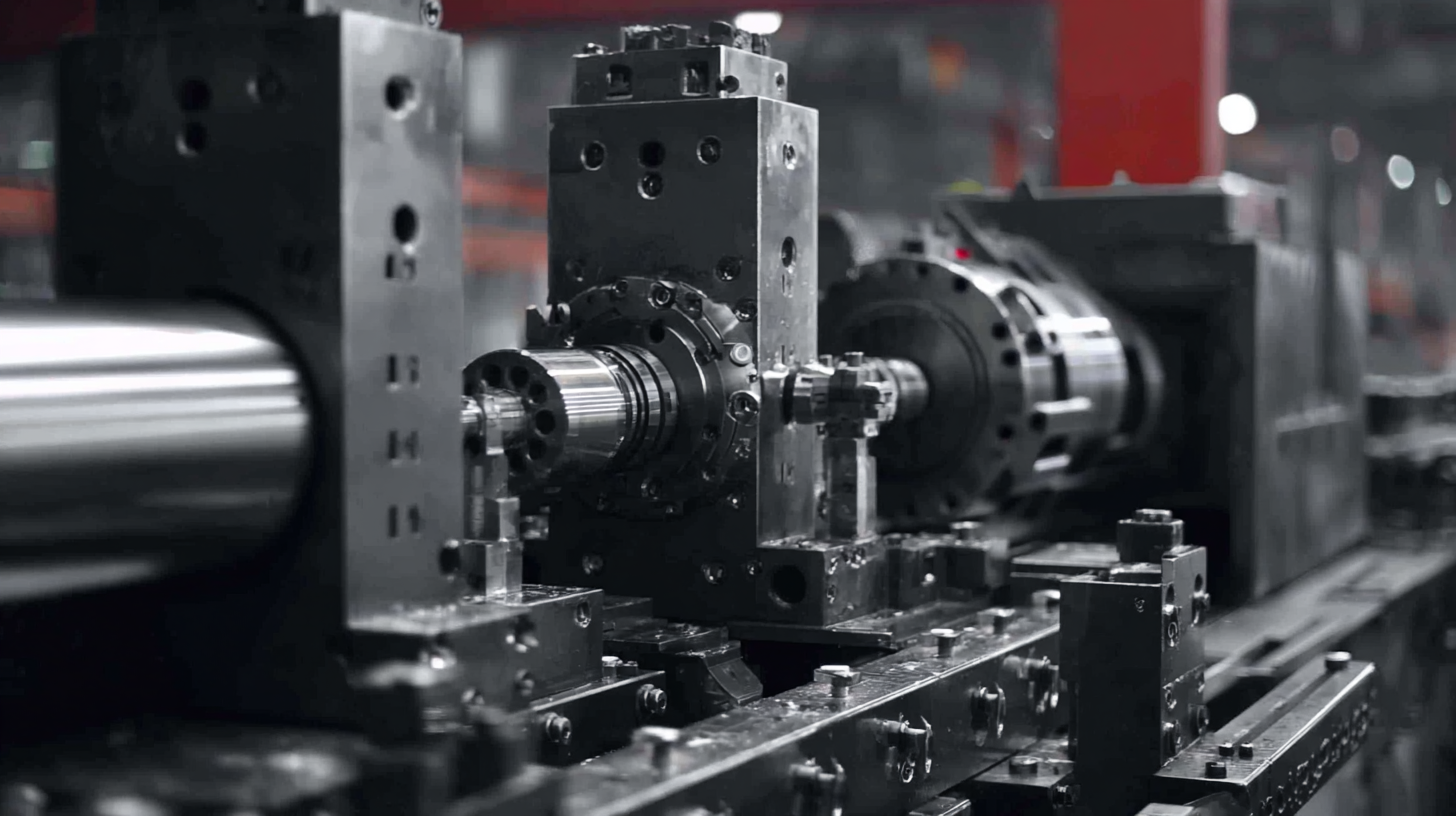

The advancements in tube mill technology have significantly improved both precision and productivity in modern industries. With innovations such as precision tube mills, manufacturers can achieve tighter tolerances and better surface finishes, which are essential for high-quality steel products. Automated bending systems further enhance the efficiency of production lines, allowing for rapid transitions between different pipe sizes and shapes without sacrificing quality.

Moreover, the integration of Industry 4.0 technologies in tube mills has revolutionized manufacturing processes. Real-time data monitoring and smart automation not only streamline operations but also enable predictive maintenance, thereby minimizing downtime. These advancements contribute to a more sustainable approach, with reduced waste and increased energy efficiency, ultimately leading to greater competitiveness in the global market for steel pipes and tubes. As industries continue to embrace these cutting-edge technologies, the future of manufacturing looks to be both innovative and promising.

In 2023, the U.S. mechanical pipe and tube market is valued at $2.44 billion, with projections to grow to $2.49 billion in 2024 and reach $2.99 billion by 2032. This growth trajectory underscores the increasing demand for innovative techniques in steel pipe production, particularly with the integration of advanced technologies such as Artificial Intelligence (AI) and the Internet of Things (IoT). The implementation of AI facilitates data-driven decision-making, enhancing efficiency and quality in pipe manufacturing processes, while IoT devices provide real-time monitoring and maintenance alerts, reducing downtime and waste.

The adoption of these technologies also supports various applications within the market, including seamless and welded pipes for industries like oil and gas, automotive, and construction. As manufacturers leverage AI for predictive analytics and IoT for process optimization, they not only meet regulatory standards but also address the evolving needs of modern industries. This synergistic approach to technology and production is shaping the future of the steel pipe and tube sector, enabling companies to enhance their competitiveness in a rapidly growing market.

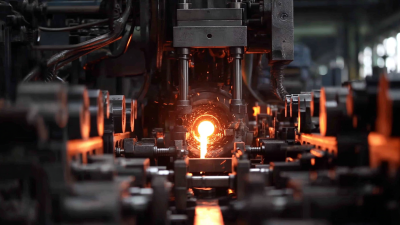

Sustainable practices in steel manufacturing are becoming increasingly vital as industries strive to reduce waste and energy consumption. According to the World Steel Association, the global steel industry is responsible for approximately 7% of total greenhouse gas emissions. To combat this, innovative techniques are being employed in steel pipe machines and tube mills, with a strong focus on reducing the carbon footprint. Advanced technologies such as electric arc furnaces (EAFs) have gained traction, as they utilize recycled scrap steel and can lower energy consumption by up to 70% compared to traditional blast furnaces.

Additionally, organizations are adopting lean manufacturing principles to minimize waste in the production process. For instance, a report from the American Iron and Steel Institute highlights that over the past decade, steel companies have improved scrap metal recycling rates to over 90%. By integrating real-time monitoring systems and utilizing data analytics, industries can optimize production schedules, streamline operations, and ensure that excess materials are reduced, thus leading to a more sustainable approach to steel manufacturing. This commitment to environmental responsibility not only meets regulatory requirements but also enhances corporate reputation and operational efficiency in an ever-demanding market.

The demand for high-strength steel pipes continues to surge as industries strive to meet rigorous standards and enhance performance. According to recent projections, the market for stainless steel seamless pipes is anticipated to reach USD 5.15 billion by 2030, highlighting a significant opportunity for manufacturers to innovate and refine their production techniques. This growth is driven by the increasing need for durable, high-quality piping solutions in construction, automotive, and oil & gas sectors.

To stay competitive in this evolving landscape, businesses must focus on advanced techniques in steel pipe manufacturing. The advent of precision engineering and sophisticated tooling processes, such as those developed by top manufacturers, plays a crucial role in producing high-strength steel pipes that meet industry specifications. These innovations not only improve product quality but also optimize production efficiency, setting a benchmark for meeting the burgeoning industry demands.

**Tips:** Regularly assess market trends and invest in cutting-edge machinery to enhance production capabilities. Collaborating with industry experts can also provide invaluable insights into the latest technological advancements, ensuring that companies remain at the forefront of the steel pipe market. Emphasizing sustainable practices could further position businesses favorably in a competitive environment.

| Dimension | Measurement | Technology Used | Strength Rating (MPa) | Applications |

|---|---|---|---|---|

| Outer Diameter | 50 mm - 500 mm | Seamless Pipe Technology | 450 MPa | Automotive, Construction |

| Wall Thickness | 5 mm - 20 mm | ERW Technology | 380 MPa | Structural, Oil & Gas |

| Length | 6 m - 12 m | Direct Spiral Weld Technology | 500 MPa | Piping Systems, Heavy Industries |

| Coating Thickness | 50 µm - 300 µm | Galvanizing, Anti-corrosion Coating | N/A | Marine, Infrastructure |