As the manufacturing sector continues to embrace advanced technologies, the role of High Frequency Welded Steel Pipe Making Machinery becomes increasingly critical. According to a report by MarketsandMarkets, the global market for welded pipe production is expected to reach $54 billion by 2025, driven by the growing demand in construction, automotive, and oil and gas industries. Innovations showcased at the 138th Canton Fair in 2025 highlight the latest advancements in efficiency and productivity for these machines, which utilize high-frequency electric currents for optimal weld quality and strength. The fair serves as a pivotal platform for industry experts and manufacturers to exchange insights and explore cutting-edge technologies that enhance the production of high-frequency welded steel pipes, addressing not only current industry challenges but also paving the way for future developments in material science and engineering.

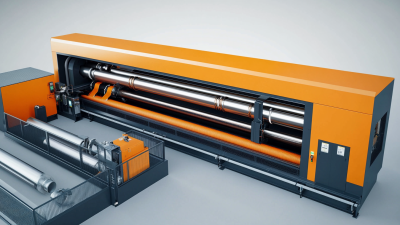

The 138th Canton Fair 2025 promises to showcase groundbreaking advancements in the manufacturing of high frequency welded steel pipes. Innovative technologies emerging in this sector are revolutionizing traditional methodologies, enhancing efficiency, and elevating product quality. Automated systems integrating artificial intelligence and machine learning are streamlining the welding process, ensuring precision and minimizing human error. These cutting-edge innovations facilitate rapid production cycles while significantly reducing operational costs.

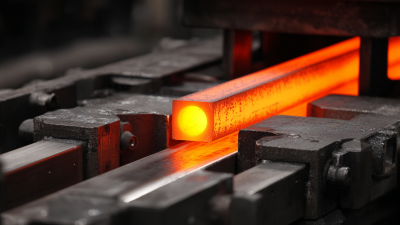

Moreover, advancements in materials science have led to the development of superior welding electrodes and coatings that enhance the durability and strength of the welded joints. The introduction of real-time monitoring systems also plays a crucial role in quality control, allowing manufacturers to detect issues instantaneously and ensuring that every product meets stringent industry standards. As the demand for high frequency welded steel pipes in various applications continues to grow, these technological transformations are setting a new benchmark for productivity and excellence in the industry.

The market for high frequency welded steel pipe machinery is poised for significant growth as industry trends indicate a robust demand for infrastructure development and energy expansion worldwide. According to a recent report by Market Research Future, the global market for welded steel pipes is expected to reach USD 27 billion by 2026, growing at a CAGR of 6.2% from 2021. This growth is driven by increasing investments in construction projects and stringent regulations aimed at enhancing the quality standards of steel products in various applications.

Innovations in high frequency welding technology are directly addressing the evolving needs of the market by improving efficiency and reducing production costs. The latest advancements in machinery allow for faster processing speeds and higher precision in weld quality, which are critical for meeting the stringent requirements in sectors such as oil and gas, automotive, and construction. A study published by Allied Market Research highlights that the adoption of automated machinery is expected to rise by over 30% in the upcoming years, reflecting the industry's shift towards smart manufacturing solutions and increased competitiveness in the marketplace.

The 138th Canton Fair in 2025 serves as a prime exhibition ground for innovations in high-frequency welded steel pipe making machinery, particularly highlighting the significant strides in automation that are transforming the efficiency of steel pipe production. The integration of advanced automation systems not only streamlines the manufacturing process but also enhances precision, reducing waste and operational costs. As industries increasingly seek to optimize their production lines, the automation trend signifies a shift towards more sustainable and economically viable manufacturing practices.

Moreover, the recent discussion surrounding tariffs on steel and aluminum has amplified the importance of domestic production capabilities. With support from local manufacturers, the emphasis on automated machinery stands to bolster the manufacturing sector in response to international competition and policy changes. Automation is poised to play a pivotal role as manufacturers look to adapt to evolving market conditions while maintaining high standards of productivity and efficiency. As seen in the context of the Canton Fair, the adoption of these technologies is not just a response to economic pressures but also a proactive approach to ensuring long-term growth and stability in the steel industry.

At the 138th Canton Fair 2025, sustainability trends in high frequency welded steel pipe making machinery take center stage, reflecting the industry's commitment to eco-friendly practices. High frequency welding technology has evolved to incorporate energy-efficient systems that significantly reduce power consumption during the manufacturing process. By utilizing innovative designs and advanced materials, manufacturers are not only lowering their carbon footprint but also minimizing waste, leading to a more sustainable pipeline production cycle.

Furthermore, these sustainability trends resonate deeply with global regulatory frameworks focusing on environmental conservation. The integration of smart technologies, such as real-time monitoring and predictive maintenance, enables manufacturers to optimize their operations while adhering to stricter emissions standards. This shift not only benefits the environment but also enhances the competitiveness of companies in the global market. As stakeholders in the industry embrace these advancements, the move towards sustainable practices will likely shape the future of high frequency welding machinery, fostering a more responsible and innovative manufacturing landscape.

| Innovation Type | Description | Sustainability Impact | Industry Relevance |

|---|---|---|---|

| Energy Efficient Systems | Integration of energy-efficient motors and drives to reduce electricity consumption. | Significant reduction in carbon footprint and operational costs. | Key for manufacturers aiming for lower energy consumption targets. |

| Waste Reduction Technologies | Advanced cutting and welding techniques that minimize material waste. | Helps achieve sustainability goals by reducing scrap material. | Gaining traction in companies focused on circular economy principles. |

| Automated Quality Control | Use of AI and machine learning for precise quality assessment during production. | Reduces defect rates, increasing the lifespan of products and reducing waste. | Relevant for industries where product quality cannot be compromised. |

| Eco-friendly Materials | Shift towards using recycled metals and sustainable sourcing practices. | Lower environmental impact and improved resource efficiency. | Appealing to modern consumers and regulatory bodies prioritizing sustainability. |

| Smart Machinery | Integration of IoT devices for real-time monitoring and data analysis. | Optimizes energy usage and maintenance, contributing to longer machinery life. | Critical for manufacturers looking to innovate and stay competitive. |

At the upcoming 138th Canton Fair in 2025, major players in the steel pipe manufacturing sector will showcase innovations in high-frequency welded steel pipe making machinery. With the stainless steel seamless pipes market projected to reach USD 5.15 billion by 2030, manufacturers are increasingly focused on enhancing operational efficiency and product quality. This shift is driven by rising demand across various industries, including construction, automotive, and energy, necessitating advancements that can keep pace with market growth.

Competitor analysis reveals that firms adopting cutting-edge technologies and sustainable practices are likely to dominate the market. Innovations such as automated welding processes, advanced quality control systems, and eco-friendly materials are essential for maintaining competitive advantages. As companies strive to meet evolving regulatory standards and consumer preferences, participation in events like the Canton Fair becomes crucial for networking and establishing benchmarks in manufacturing capabilities. The emerging trends are not just confined to machinery; they also encompass strategies that improve overall production efficiencies while reducing environmental impacts, thereby reshaping the landscape of the steel pipe manufacturing sector.