In the ever-evolving landscape of manufacturing, High Quality Steel Pipe Machines Tube Mill stand at the forefront. These machines play a crucial role in producing high-strength steel pipes. With the demand for durable and efficient pipes increasing, the need for advanced manufacturing technology becomes clear.

As we look ahead to 2026, it's vital to explore the trending innovations in this sector. There are challenges to overcome, such as maintaining quality while enhancing productivity. Companies must adapt to changing standards and consumer expectations. Some manufacturers may struggle to keep pace, highlighting the importance of investment in technology.

The success of High Quality Steel Pipe Machines Tube Mill hinges not only on the machinery itself but also on the skilled workforce. Training and expertise are essential. Without a knowledgeable team, even the best machines can underperform. Thus, while technology progresses, the human element remains indispensable in achieving excellence.

The tube mill technology plays a crucial role in the production of steel pipes. This process involves the continuous forming of flat steel strips into tubular shapes. An impressive figure to note is that the global tube mill market is expected to grow at a CAGR of 4.5% until 2026. This growth indicates an increasing demand for high-quality steel pipes.

Modern tube mills feature advanced automation and precision control. These systems ensure higher production efficiency and lower waste. Interestingly, a recent report highlighted that up to 20% of material can be wasted during traditional production processes. By implementing newer technologies, manufacturers can significantly reduce this waste.

Moreover, sustainability is becoming increasingly important. The steel industry emitted around 2.1 billion tons of carbon dioxide in 2022. Reducing emissions requires innovative tube mill designs that are more energy-efficient. Many companies are reflecting on their production methods. They know that improvements are necessary to meet environmental regulations and market pressures. Adapting to such changes is essential for long-term growth in the steel pipe sector.

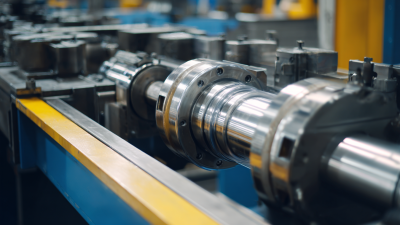

High-quality steel pipe machines are essential in modern manufacturing. These tube mills play a critical role in producing various steel pipes. Important features to look for include precision engineering and durability. Machines should handle different sizes of steel with ease. Operators benefit from user-friendly interfaces that simplify complex processes.

Efficient production is another key aspect. Well-designed mills optimize the manufacturing line, reducing downtime. High-speed operation can significantly increase output. However, challenges may arise in maintaining consistent quality. Regular checks and maintenance are vital for performance. Without proper attention, machines may falter.

Lastly, flexibility is crucial. A machine that can adapt to various pipe specifications can save time and resources. This adaptability often correlates with innovation in design. Manufacturers should not overlook the importance of ongoing training for operators. An educated team ensures the machines are used to their fullest potential, leading to better results. In the end, investing in quality steel pipe machines is a reflection of commitment to excellence in production.

Innovative designs in tube mills are crucial for enhanced efficiency in steel pipe manufacturing. Recent studies show that productivity can increase by 30% with the latest technology. These innovations include advanced automation, which reduces manual intervention. Machines now come equipped with smart sensors, capable of real-time monitoring. This feature minimizes downtime and improves overall production flow.

In addition to automation, energy efficiency is a growing concern. Modern tube mills utilize energy-saving motors and optimized processes. Reports indicate that energy consumption can be reduced by 25% using these new designs. However, the initial investment in these technologies can be daunting for some manufacturers. The need for skilled operators also remains a challenge. This gap highlights the potential for ongoing training in the industry.

Furthermore, integrating artificial intelligence into production processes is still in its infancy. While promising, it requires significant investment and expertise. Many manufacturers hesitate to implement these changes. Balancing cost and innovation is key. As the industry evolves, understanding these dynamics will be essential for those aiming to remain competitive.

The tube mill equipment market has been evolving rapidly. As of 2023, the global demand for high-quality steel pipe machines is projected to grow by 4.5% annually. This trend signals a strong future for tube mills. Factors like urbanization and infrastructure development drive this growth. Countries in Asia, especially China and India, lead the expansion in manufacturing capabilities.

However, challenges remain. Many manufacturers struggle with high energy costs and raw material prices. The average cost of high-grade steel has increased by 15% over the last year, creating pressure on profit margins. Additionally, there is a growing emphasis on sustainability. Companies must adapt their practices. Implementation of energy-efficient technologies is no longer optional—it's a necessity.

Industry reports indicate a significant shift toward automation by 2026. Over 30% of tube mills are expected to integrate advanced robotics. This shift aims to improve efficiency and reduce labor costs. Continuous advancements in technology can bridge existing gaps in production. Nevertheless, the transition can be daunting. Many firms lack the resources to invest in new technologies, making it difficult to compete.

This chart displays the projected market size of steel pipe machines tube mills from 2018 to 2026. The data indicates a significant increase in market value, showcasing growth trends and future outlooks for tube mill equipment.

When selecting a tube mill manufacturer, several factors are crucial. Quality is paramount. According to a recent industry report, over 70% of manufacturers prioritize durability and precision in machine construction. A tube mill that consistently produces high-quality products reduces waste and increases efficiency.

Another factor is technology integration. The latest data shows that firms utilizing advanced automation see a 30% boost in productivity. Automated systems improve consistency, making it easier to meet tight deadlines. However, some manufacturers lag in adopting new technology. This gap can hinder growth and market competitiveness.

Finally, customer support cannot be overlooked. A 2022 survey indicated that 65% of manufacturers faced issues due to inadequate post-sale support. Having reliable service is essential for minimizing downtime. Ineffective communication or poor parts availability can lead to significant production losses. Choose a manufacturer that not only sells machines but also offers ongoing support and training. These elements ensure a productive partnership in the long term.

| Feature | Description | Consideration |

|---|---|---|

| Production Capacity | Max output per hour | Ensure it meets your volume needs |

| Material Quality | Type of steel used in manufacturing | Look for high-grade materials for durability |

| Energy Efficiency | Power consumption levels | Lower costs and better sustainability |

| Automation Technology | Level of automation offered | Consider ease of operation and maintenance |

| Customization Options | Flexibility in design and features | Align with specific production requirements |

| Support and Service | Availability of technical support | Check for warranty and service terms |

| Lead Time | Time from order to delivery | Plan ahead for production timelines |