The demand for High Frequency Welded Steel Pipe Making Machinery is growing rapidly. In recent years, the global steel pipe market has expanded significantly, with a projected CAGR of 3.5% from 2021 to 2026. This growth highlights the need for efficient production technologies. High frequency welded steel pipes are critical in industries like construction and automotive.

High Frequency Welded Steel Pipe Making Machinery increases production speed and efficiency. This technology allows manufacturers to produce pipes with minimal waste and high precision. Reports indicate that companies using advanced welding machinery see up to 20% lower production costs. However, transitioning to this technology can pose challenges. Companies must invest in training and maintenance to maximize benefits.

Investing in High Frequency Welded Steel Pipe Making Machinery is crucial for staying competitive. However, it requires careful consideration of costs and operational adjustments. Companies must reflect on their current capabilities and future needs. Advancements offer great potential, but they also demand adaptability and constant evaluation of processes.

High Frequency Welding (HFW) plays a vital role in steel pipe production. It offers efficient and high-quality welds, essential for modern industrial applications. According to industry reports, HFW technology increases production speeds by up to 40%. This boost leads to greater output and efficiency in manufacturing processes.

HFW helps produce robust pipes. These pipes are crucial in various sectors, including construction and energy. Notably, high-frequency welded pipes can withstand high-pressure conditions, which is a significant advantage. Experts estimate that over 60% of steel pipes used in infrastructure projects utilize HFW methods.

Tips: To ensure quality, always monitor the welding parameters closely. Small variations can lead to significant defects. Regular maintenance of welding equipment is essential to sustain optimal performance.

Attention to detail is paramount in steel pipe production. Even minor imperfections could compromise structural integrity. It's important to reflect on the processes and continuously seek improvements. The industry must adapt to evolving standards and technologies. Embracing HFW is not just beneficial but necessary for staying competitive.

| Dimension | Value | Importance in Industry |

|---|---|---|

| Pipe Diameter | 1 - 10 inches | Versatility in various applications. |

| Welding Speed | Up to 100 m/min | Increases productivity and efficiency. |

| Material Strength | Up to 600 MPa | Ensures durability and reliability. |

| Energy Consumption | Low, approx. 1 kWh/m | Cost-effective production. |

| Welding Technique | High Frequency Induction | Provides high-quality welds. |

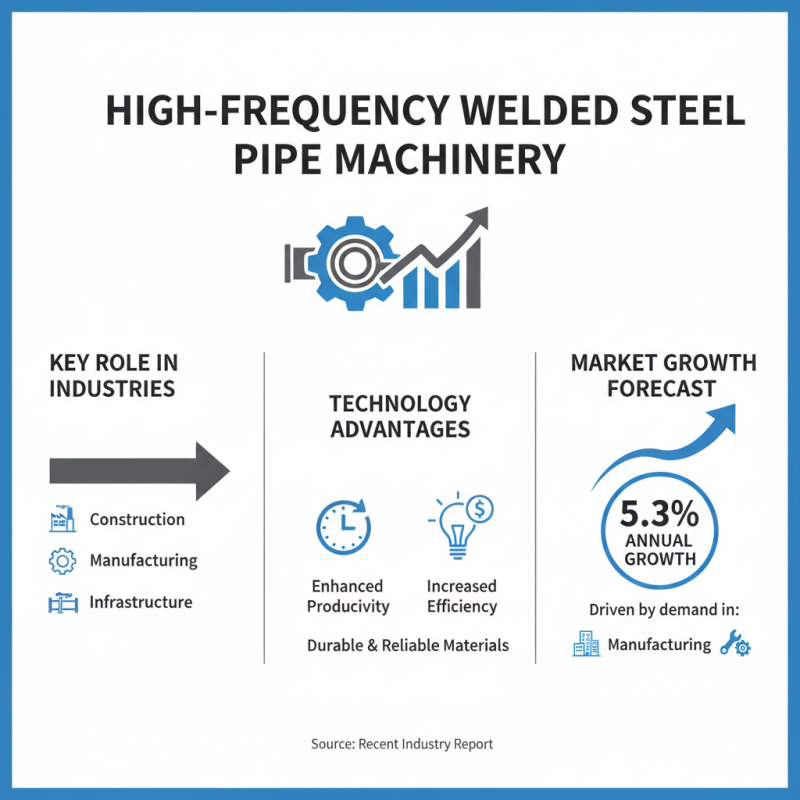

High frequency welded steel pipe making machinery plays a crucial role in various industries. This technology provides significant advantages that enhance productivity and efficiency. According to a recent industry report, the market for welded steel pipes is expected to grow by 5.3% annually. This trend reflects the increasing demand for durable and reliable materials in construction and manufacturing.

One key advantage of high frequency welding is its speed. The process allows for rapid production, cutting down manufacturing time. Typically, it can produce pipes at rates of up to 30 meters per minute. This high throughput meets the growing market needs, especially in sectors like oil and gas. Additionally, the quality of welded joints can match that of seamless pipes, making it a cost-effective alternative.

Tip: Regular maintenance of machinery can prevent costly downtime. Operators should ensure all components are checked frequently.

Another benefit is versatility. High frequency welded steel pipes can be used in various applications, from structural support to fluid transport. This adaptability is vital as industries evolve. However, it is essential to reflect on the environmental impact of production processes. Innovations in green technologies are needed to make welding practices more sustainable.

Tip: Consider energy-efficient models that minimize waste. They can lower operational costs and reduce environmental footprints.

High frequency welded steel pipes are increasingly vital in various industries. These pipes have diverse applications, making them essential for modern manufacturing. They are commonly used in the construction sector. Building frameworks often rely on strong, durable materials. High frequency welded steel pipes offer just that, combining strength with flexibility.

In the automotive industry, these pipes are critical for manufacturing exhaust systems. They withstand high temperatures and corrosive elements. Furthermore, the oil and gas sectors utilize these pipes for transporting fluids and gases. Their ability to handle high pressure situations makes them indispensable. Despite their advantages, some manufacturers face challenges. The technology can be complex and requires skilled operators. There’s a need to constantly innovate in the production process.

The agricultural sector also benefits from high frequency welded steel pipes. They provide sturdy structures for irrigation systems. However, the environmental impact of these materials must be considered. Recycling and sustainability are areas where companies can improve. Overall, while high frequency welded steel pipes play a crucial role across industries, ongoing reflection on their production and recycling is essential.

High-frequency welded steel pipe machinery has seen rapid advancements. These innovations are pivotal for industries demanding high efficiency and precision. New technologies enhance welding speed and accuracy. They reduce production costs while maintaining product quality. The integration of automation has further streamlined operations.

Tips: Always assess machinery for versatility. High-frequency equipment can handle various steel grades, which adds flexibility. This adaptability can be crucial in meeting diverse market demands. However, over-reliance on automation may lead to skill gaps. Workers must still hone manual welding skills for complex tasks.

New features like real-time monitoring systems allow immediate adjustments. This ensures consistent quality control. However, not all operators may be trained to use these systems effectively. Proper training is essential to maximize machine capabilities. Operators should regularly review performance metrics to identify areas for improvement.

High frequency welding technology is revolutionizing industries across the globe. Its efficiency and speed are unmatched. The future of this technology looks promising, with innovations on the horizon. New techniques are emerging, focusing on improving energy efficiency and reducing waste. Manufacturers are prioritizing sustainability. They aim to create stronger, lighter welds, which can help in various applications, from construction to automotive.

Tips: Ensure you regularly update your machinery. Keeping equipment in check boosts productivity. Adopt energy-efficient practices to align with future standards.

As industries evolve, the need for high frequency welded steel pipes increases. These pipes are crucial in sectors like oil, gas, and construction. Next-generation machines will integrate AI and automation. This will lead to enhanced precision. However, challenges exist. Transitioning to new technology can be costly. Training staff and upgrading systems require time and resources.

Tips: Invest in training programs for your workforce. Skilled operators optimize machine use and minimize errors. Consider conducting audits of your welding processes; this will reveal areas needing improvement.