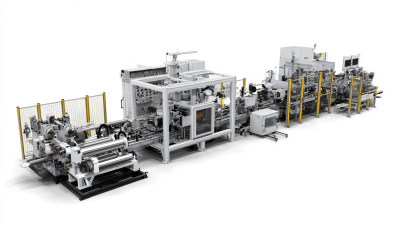

In the dynamic world of manufacturing, optimizing efficiency is paramount. The "High Frequency Tube Mill Making Machine" plays a crucial role in this sector. Its ability to produce high-quality tubes in bulk makes it indispensable. However, many operators struggle to maximize its potential. Understanding key tips can transform production processes.

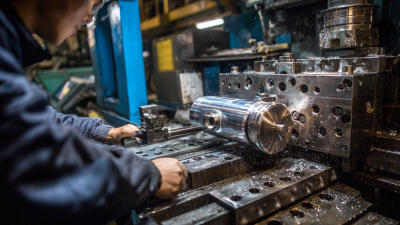

Efficiency does not happen by chance. It requires attention to detail and constant evaluation. Regular maintenance of the High Frequency Tube Mill Making Machine is essential. This will prevent unexpected breakdowns and costly downtime. Additionally, training operators to understand the machine’s functions can lead to smoother operations.

Every step in the production process counts. Even minor adjustments can lead to significant improvements. Operators should reflect on their methods and be open to change. Analyzing previous production runs helps identify areas for enhancement. In a competitive market, small changes can create a big impact. Embracing these insights can boost the overall productivity of the High Frequency Tube Mill Making Machine.

High frequency tube mills play a critical role in modern manufacturing processes. They are essential for producing pipes and tubes used in various industries. Reports indicate that the global market for tube mills is projected to reach $8.1 billion by 2027. The efficiency of these machines significantly impacts production costs.

Optimizing the performance of tube mills is vital. Regular maintenance can help prevent costly downtimes. Studies show that mills operating at higher speeds can increase output by 20% or more. However, the increased speed must be balanced with quality control measures. If not, defects can rise, leading to waste and rework.

The importance of troubleshooting cannot be overstated. Identifying and addressing issues promptly can save substantial resources. Moreover, many manufacturers overlook the need for skill development among their operators. Skilled workers are crucial for maximizing efficiency. A recent survey highlighted that only about 30% of operators receive adequate training on new technologies. This gap presents an opportunity for improvement in the industry.

High frequency tube mill machines are essential in modern manufacturing. Key components play crucial roles in achieving optimal functionality and efficiency. The forming section, for instance, shapes the metal into tubes. A good forming roller design reduces production time by up to 25%, enhancing output significantly.

Welding is another vital component. High frequency induction welding offers quick and strong seams. Industry reports indicate that this process can improve welding speeds by as much as 40%. However, improper machine setup can lead to weak welds, necessitating adjustments for consistency. The cooling system also deserves attention. Effective cooling minimizes defects in the final product, but inadequate cooling could compromise quality and lead to costly reworks.

Another overlooked element is the drive system. Vibration issues during operation can signal wear and tear. Regular maintenance can reduce failures and downtime by 30%. Operators often underestimate the importance of calibration, which ensures that every component works in harmony. As a result, even small adjustments can lead to substantial efficiency gains.

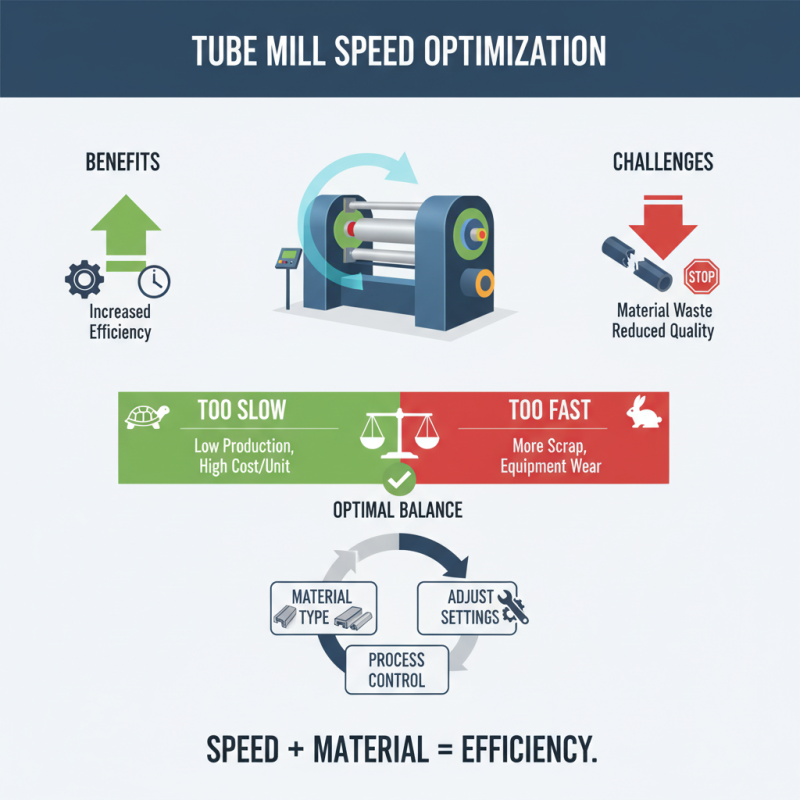

Optimizing the speed of a tube mill can significantly impact overall efficiency. Achieving the right balance between speed and material utilization is critical. Operators often need to tweak settings based on the material being processed. Each type of material can behave differently under similar conditions. A mill running too fast may increase scrap rates. This can negate any gains from quicker production times.

Here are some tips to consider: Monitor the feed rate closely. A consistent feed can reduce fluctuations in the mill's performance. Inspect the tooling regularly. Worn tools can lead to poor cuts and increased waste. Adjustments may be needed to find the sweet spot for each job. Every mill has its quirks. Understanding these can unlock hidden efficiencies.

Increasing operational efficiency also requires attention to detail. Train operators to recognize signs of inefficiency. Sometimes, simple tweaks can yield substantial savings. This includes adjusting the coolant flow or recalibrating the alignment. Encourage feedback from the team. Their insights can reveal areas for improvement. Every small change can add up over time.

Maintaining consistency in tube production is crucial for ensuring high-quality output. Quality control measures play a significant role in this process. Regular inspections can help detect issues early, but they must be thorough. Visual checks can miss fine details. Emphasizing precision in measurements is essential for achieving uniformity across production runs.

Another effective method is to implement statistical process control. This technique allows for real-time monitoring of production variables. By analyzing data, manufacturers can identify trends and make adjustments promptly. However, relying solely on technology can lead to oversight. Human judgment still matters in identifying anomalies that data may not capture.

Training staff on quality standards is vital. Skilled workers can recognize subtle signs of defects more effectively. Yet, ongoing training sometimes falls short due to time constraints. Regular feedback loops can foster a culture of quality, but they require commitment. Ultimately, maintaining consistency hinges on a combination of precise measurements, effective monitoring, and skilled personnel.

| Quality Control Measure | Description | Frequency | Impact on Efficiency |

|---|---|---|---|

| Visual Inspection | Regular visual checks for surface defects and uniformity. | Every shift | Early detection of issues reduces waste. |

| Dimensional Checks | Measurement of tube dimensions at key production stages. | Hourly | Ensures product meets specifications, reducing rework. |

| Material Quality Tests | Testing raw materials for strength and consistency. | Daily | Improves overall durability of the final product. |

| Welding Inspections | Assessment of weld integrity and consistency. | Per batch | Critical for ensuring product strength and reliability. |

| Final Product Testing | Tests on the final product for tensile strength and yield. | Before shipment | Confirms product meets industry standards, reducing returns. |

In the world of high frequency tube mills, efficiency is key. Innovations are emerging that drive significant improvements. Technologies like automation and real-time monitoring are changing how mills operate. These advancements help reduce downtime and enhance productivity. However, integrating new technology can sometimes overwhelm existing systems.

To increase efficiency, consider a few handy tips. Regular maintenance of the machinery is crucial. Small issues can escalate quickly, leading to costly downtimes. Streamlining workflows can also have a significant impact. Ensure that all operators are well-trained in the latest equipment. Continuous learning helps in adapting to innovations.

Moreover, keep an eye on emerging market trends. Sustainability is becoming increasingly important. Exploring eco-friendly practices not only attracts clients but also boosts efficiency. Balancing modern techniques with traditional practices may require adjustments, but it's worth the effort. Embrace change, yet reflect on what works best for your operation.