High Frequency Pipe Welding Machines have become a cornerstone in modern manufacturing, particularly in the production of high-quality steel pipes for various industrial applications. The global market for these machines is projected to grow significantly, reaching approximately $1.2 billion by 2025, driven by increasing demand for durable and efficient pipe solutions across sectors such as oil and gas, construction, and infrastructure. This growth is fueled by innovations in welding technology that enhance precision and speed, thereby improving overall productivity.

These machines operate using advanced high-frequency electrical energy to create welds that are not only stronger but also more efficient than traditional welding methods. According to a recent industry report, the adoption of High Frequency Pipe Welding Machines can reduce production costs by up to 30%, while simultaneously increasing output quality. As industries shift towards automation and seek to meet higher standards of safety and performance, the utilization of such machines is expected to rise exponentially. Understanding the workings of High Frequency Pipe Welding Machines is crucial for manufacturers aiming to stay competitive in a rapidly evolving market.

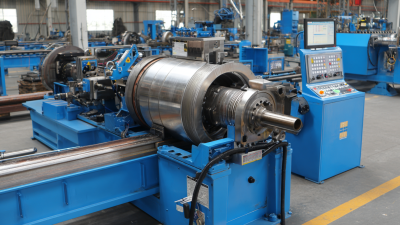

High frequency pipe welding machines are specialized equipment designed to join metal pipes using high-frequency electric currents. Typically seen in industries such as oil and gas, construction, and manufacturing, these machines rely on electromagnetic induction to create heat and facilitate the welding process. A high frequency welder consists of a power supply, an oscillator, a welding head, and cooling systems. The power supply converts the input current to a high-frequency output, while the oscillator generates the electromagnetic field necessary for the welding process. The welding head then applies pressure to the edges of the pipe, allowing for a seamless join upon heating.

The efficiency of high frequency pipe welding machines can significantly reduce production time and improve weld quality compared to traditional methods. According to industry reports, the global market for high frequency welding equipment is anticipated to grow at a CAGR of 5.4% from 2021 to 2028, indicating a growing demand for these machines in diverse sectors. Additionally, due to the ability to process various pipe sizes and materials, high frequency welding technology is becoming increasingly favored for its versatility. This rise in popularity underscores the importance of understanding the components and functions of high frequency pipe welding machines for industries seeking to enhance their productivity and quality standards.

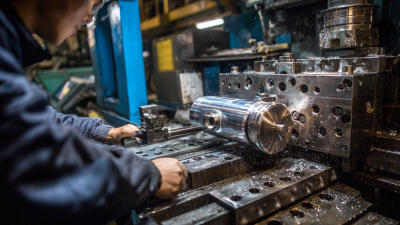

High frequency pipe welding is a specialized process that leverages electromagnetic energy to join metal tubes efficiently and effectively. At the core of this technology lies the principle of induction heating, which generates heat directly within the material being welded. By applying high-frequency currents to the pipe's surface, the method quickly raises the temperature to the melting point of the base metal, enabling a strong and consistent weld. This approach not only reduces the thermal distortion common in traditional welding techniques but also enhances production speed due to its rapid heating capabilities.

High frequency pipe welding is a specialized process that leverages electromagnetic energy to join metal tubes efficiently and effectively. At the core of this technology lies the principle of induction heating, which generates heat directly within the material being welded. By applying high-frequency currents to the pipe's surface, the method quickly raises the temperature to the melting point of the base metal, enabling a strong and consistent weld. This approach not only reduces the thermal distortion common in traditional welding techniques but also enhances production speed due to its rapid heating capabilities.

The techniques used in high frequency welding include the application of carefully designed coil systems that create a concentrated electromagnetic field. This field is precisely tuned to match the frequency of the current, which typically ranges from 100 kHz to several megahertz. The process can be adapted for various pipe sizes and materials, making it versatile for different manufacturing needs. Furthermore, modern high frequency welding machines incorporate advanced controls to monitor and adjust parameters in real time, ensuring high-quality welds with minimal operator intervention.

High frequency welding has become a pivotal technology in the pipe manufacturing industry. This method allows for the efficient joining of metal pipes, particularly in applications where strength and durability are paramount. Industries such as oil and gas, construction, and automotive frequently utilize high frequency pipe welding due to its ability to produce high-quality welds at remarkable speeds. The process relies on electromagnetic induction, which generates heat quickly and allows for precise control over the weld joint, ensuring minimal material distortion and maximum integrity in the finished product.

In addition to traditional applications, high frequency welding is increasingly being adopted in the manufacturing of specialty pipes, including those used in chemical processing and food production. The process is particularly advantageous for producing pipes that require specific physical or chemical properties, as it enables manufacturers to maintain tight tolerances and achieve consistent results. Furthermore, the rapid cycle times associated with high frequency welding translate into improved productivity and cost efficiency, making it a preferred choice for modern pipe manufacturing operations.

High-frequency pipe welding has garnered significant attention in recent manufacturing sectors due to its numerous advantages over traditional welding methods. One of the key benefits is its efficiency; high-frequency welding can create continuous seams in a fraction of the time it takes traditional welding techniques. According to a report by the American Welding Society, high-frequency welding processes can reduce production time by up to 50%, leading to lower labor costs and increased output for manufacturers.

Moreover, the quality of welds produced by high-frequency welding is often superior. This technique allows for better penetration and stronger bonds, helping to minimize defects. Data from the International Institute of Welding indicates that high-frequency welded joints can achieve strength levels of 90% or more of the base material's strength, unlike traditional methods where strength levels may drop to 70-80%. This enhanced bond strength makes high-frequency welding an ideal choice for high-stress applications, particularly in industries such as oil and gas, where the integrity of piping systems is paramount.

Additionally, high-frequency welding is more environmentally friendly, producing less waste than traditional welding methods. With the increasing emphasis on sustainable practices, manufacturers adopting high-frequency technology can reduce their carbon footprint, aligning with global initiatives aimed at reducing industrial waste. Overall, the transition towards high-frequency welding presents a compelling opportunity for industries looking to enhance productivity, quality, and sustainability.

The market for high frequency pipe welding machines is expected to experience significant growth by 2025. This increase can be attributed to the rising demand for efficient and reliable welding solutions in various industries, including construction, automotive, and manufacturing. As industries continue to innovate and pursue automation, high frequency welding technology is likely to gain traction due to its ability to produce strong and precise welds at a faster rate compared to traditional methods.

Tips for selecting a high frequency pipe welding machine include assessing the machine's compatibility with the materials you intend to weld and understanding your specific production requirements. Additionally, consider the after-sales support and availability of spare parts, as these factors can greatly affect the machine's longevity and performance.

The outlook for high frequency pipe welding machines also suggests a shift towards more energy-efficient models, reflecting the broader industry trend of sustainability. Manufacturers are increasingly investing in research and development to create machines that not only meet performance benchmarks but also minimize operational costs and environmental impact. As such advancements unfold, stakeholders should remain updated on technological progress to make informed purchasing decisions.

| Dimension | 2023 Value | 2024 Forecast | 2025 Forecast | Growth Rate (%) |

|---|---|---|---|---|

| Global Market Size (Million USD) | 450 | 490 | 530 | 17.8% |

| North America Market Share (%) | 30% | 31% | 32% | 6.7% |

| Asia-Pacific Market Growth (%) | 25% | 27% | 30% | 20% |

| Technological Advancements (Rating 1-10) | 7 | 8 | 9 | 28.6% |

| Key Application Industries | Oil & Gas, Construction, Automotive, Manufacturing | |||