In the realm of pipe manufacturing, the utilization of High Frequency Pipe Welding Machines has become increasingly critical, especially with the rising demand for high-quality welded pipes in various industries. According to a recent report by Research and Markets, the global pipe welding market is projected to grow at a CAGR of over 5% from 2023 to 2030, underscoring the growing reliance on advanced welding technologies.

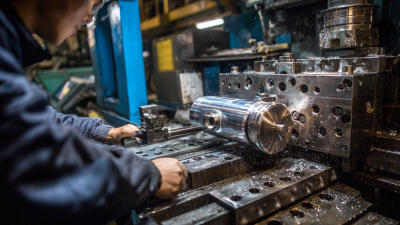

High Frequency Pipe Welding Machines, known for their efficiency and precision, are pivotal in meeting these industry demands. These machines enable manufacturers to produce welded pipes that meet stringent quality standards while optimizing production speed and reducing costs. Mastering the use of these sophisticated machines is essential for industry professionals aiming to remain competitive.

Consequently, this article will explore ten essential tips for effectively mastering High Frequency Pipe Welding Machine operations, ensuring that users can harness the full potential of this advanced technology in their welding processes.

When it comes to choosing the right high frequency pipe welding machine for your needs, the process can be daunting due to the variety of options available. Start by assessing your specific welding requirements, including the type of materials you will be working with, the thickness of the pipes, and the intended applications of your welds. Knowing your project specifications will help you narrow down the features that are critical for your machine.

One essential tip is to evaluate the power output of the welding machine. A higher power output is crucial for working with thicker materials or larger pipes, ensuring adequate heating and penetration. Additionally, consider machines that offer adjustable frequency settings. This flexibility allows you to optimize the welding process for different materials, enhancing the quality and efficiency of your welds.

Another important factor is the machine's portability and ease of use. If you will be working in various locations, a lightweight design with built-in transport features can be beneficial. Furthermore, investigate the maintenance needs and customer support offered by manufacturers. Ensuring you have access to replacement parts and technical assistance can make a significant difference in your overall productivity and machine longevity.

High-frequency welding, also known as high-frequency induction welding, is a widely adopted technique in the manufacturing industry, particularly for stainless steel pipes. This technology relies on the principle of electromagnetic induction, which allows for rapid heating and welding without direct contact. According to a report by Research and Markets, the high-frequency welding market is projected to reach $3.5 billion by 2025, driven by its efficiency and ability to produce strong, high-quality welds. Understanding the fundamentals of this technology not only enhances operational efficiency but also ensures optimal results in pipe welding applications.

When using high-frequency pipe welding machines, adhering to essential tips can significantly improve your proficiency. First, ensure that the machine settings are correctly calibrated; appropriate frequency and power adjustments correlate directly with the type and thickness of the material being welded. Additionally, maintaining clean surfaces will facilitate better fusion at the edges of the pipes, leading to stronger welds. Regularly inspecting the machines for wear and tear can also prevent operational downtime and extend the equipment's life.

Finally, keep abreast of advancements in welding technology. The industry is constantly evolving; updated methods can lead to increased productivity and cost savings. Incorporating tools like digital displays for monitoring weld quality can enhance precision and consistency. By mastering these fundamental aspects of high-frequency welding, operators can ensure they are leveraging the technology to its fullest potential.

| Tip Number | Tip Description | Benefits |

|---|---|---|

| 1 | Understand the equipment settings thoroughly. | Ensures optimal welding conditions. |

| 2 | Regularly maintain the machine. | Prolongs machine lifespan and reduces breakdowns. |

| 3 | Use proper safety gear. | Protects against hazards associated with welding. |

| 4 | Choose the right electrode for the material. | Improves weld quality and integrity. |

| 5 | Practice proper hand positioning. | Enhances control and precision during welding. |

| 6 | Monitor the cooling rate of the welded joint. | Reduces the risk of defects in the weld. |

| 7 | Familiarize yourself with high-frequency settings. | Maximizes efficiency and effectiveness of welding. |

| 8 | Adjust for different material thicknesses. | Ensures proper penetration and bond. |

| 9 | Conduct regular tests on weld strength. | Verifies integrity of welds made. |

| 10 | Keep learning through workshops and training. | Stays updated on best practices and technology. |

High frequency (HF) pipe welding equipment is a critical tool in various industries, enabling efficient and high-quality welds in materials like steel and aluminum. However, safety remains a paramount concern when operating these powerful machines. According to the American Institute of Steel Construction, nearly 1 in 10 workers in the welding industry experiences some form of workplace injury. This statistic underscores the necessity of implementing stringent safety practices to protect operators and equipment alike.

One essential safety practice involves ensuring that all operators undergo thorough training before using HF welding machinery. The Occupational Safety and Health Administration (OSHA) emphasizes the importance of this training, noting that well-informed operators are less likely to engage in risky behaviors that could lead to accidents. Moreover, regular maintenance checks on the equipment can significantly reduce the risk of malfunctions that might pose hazards during operation. Additionally, operators should always wear appropriate personal protective equipment (PPE), such as gloves, helmets, and safety glasses, to safeguard against burns, eye injury, and other potential hazards inherent in welding tasks. By adhering to these essential safety practices, companies can create a safer working environment while maximizing the efficiency of high-frequency pipe welding operations.

Mastering high frequency pipe welding techniques involves understanding both the intricacies of the welding process and how to leverage technological advancements for optimal results. Techniques such as maintaining consistent power settings, ensuring proper electrode positioning, and managing travel speed are vital for achieving high-quality welds. Emphasizing precision, welders should continuously monitor their work to avoid inconsistencies that could compromise structural integrity.

With the rise of AI technology in the welding industry, integrating smart systems can dramatically enhance efficiency and quality. For instance, deploying intelligent welding management systems, which track and optimize welding parameters in real-time, can mitigate human errors and significantly improve the output. As companies strive to upgrade their operations amidst the Industry 4.0 movement, understanding and applying these high-frequency welding methodologies, while leveraging AI innovations, will be crucial for staying competitive in today's rapidly evolving marketplace.

Maintaining a high frequency pipe welding machine is crucial for ensuring its longevity and optimal performance. One of the primary maintenance tips is to regularly check and clean the machine's filter and cooling system. Dust and debris can accumulate over time, leading to overheating and potential damage. Schedule routine inspections to assess the condition of these components and replace or clean them as necessary. Additionally, keeping welding cables and connections free from wear and corrosion not only enhances safety but also improves welding efficiency.

Another essential aspect of maintenance involves monitoring the machine's electrical components. Periodically inspect the wiring, connectors, and circuit boards for any signs of wear or damage. Promptly addressing issues such as frayed wires or loose connections can prevent more significant problems down the line. Moreover, it’s advisable to update the software regularly if applicable, as manufacturers often release updates that can improve machine efficiency and features. By adopting these maintenance practices, users can significantly prolong the lifespan of their high frequency pipe welding machines while ensuring consistent performance.