High Frequency Welded Steel Pipe Making Machinery plays a crucial role in modern manufacturing. These machines are known for their efficiency and precision. They produce high-quality steel pipes used in various industries. Understanding how to operate and maintain this machinery is vital for achieving optimal results.

Proper setup of High Frequency Welded Steel Pipe Making Machinery is essential. Operators must check parameters like temperature and pressure. Modifications may be required for different pipe specifications. Training workers effectively can prevent costly mistakes. Regular maintenance should not be overlooked. Over time, wear and tear can affect machine performance.

Not all challenges have easy solutions. Some operators struggle with inconsistent weld quality. This issue can stem from various factors. Analyzing the welding process regularly can help identify faults. Seeking expert advice when needed is also a good practice. Each step in managing this machinery requires careful consideration.

High frequency welded steel pipe making machinery plays a vital role in modern manufacturing. This equipment is designed to produce pipes efficiently and at a high speed. According to recent industry reports, global demand for welded steel pipes is projected to grow at a rate of 5.2% annually, reaching over 100 million tons by 2025. This growth drives the need for advanced welding technology.

The machinery typically employs high-frequency induction heating. It fuses the edges of the pipe together, creating a strong bond. This process is fast, often completing a weld in less than a second. However, the machinery is complex and requires skilled operators. Many companies struggle with initial setup and maintenance issues. Reports indicate that nearly 30% of manufacturers face downtime due to equipment failure.

Despite its advantages, the technology isn't without challenges. Some manufacturers have noted inconsistencies in weld quality. Variations in materials and environmental conditions can affect results. Constant monitoring and adjustments are necessary to maintain high standards. The industry's focus should shift towards improving training and better technologies to mitigate these issues.

High frequency welded steel pipe production involves several key components that are crucial for efficiency and quality. One significant part is the welding machine itself. This equipment must be reliable and designed to handle various pipe sizes. Operators often face challenges in maintaining consistent welding parameters, which can impact the final product. This leads to the need for frequent adjustments and checks.

Another important component is the pipe forming section. Proper alignment and shaping are essential for achieving the desired pipe properties. Any misalignment can result in defects or weak spots. This is often overlooked, leading to increased scrap rates. Regular inspection of this equipment can prevent costly mistakes.

Lastly, cooling systems play a vital role in ensuring the welded seam's integrity. The cooling process must be carefully controlled. Insufficient cooling may stress the weld. However, excessive cooling could lead to brittleness. Balancing this process requires constant monitoring, and even experienced operators can struggle here. Adjustments may need to be made on the fly, reflecting the dynamic nature of this production line.

The welding process in high frequency welded steel pipe making involves specific technologies and techniques. Understanding this is crucial for production efficiency. High-frequency welding typically operates at frequencies between 100 kHz and 300 kHz. This allows the steel pipes to achieve strong welds rapidly. According to a recent study by the American Welding Society, proper settings can improve weld quality by up to 30%.

One essential tip is to maintain tight tolerances on the tube edges. Small gaps can lead to weak welds. Continuous monitoring of the temperature is also vital. An optimal temperature range ensures the correct melting point for the material. Using advanced sensors can help achieve this.

Another aspect to consider is the material selection. Not all steel types weld equally. Certain grades require specific parameters. Not addressing this could lead to fractures in the welds. Operators must train in these specifications to avoid costly mistakes. Adjustments may be needed as different materials react differently under high frequency.

Finally, regular maintenance of the machinery is vital. Neglect can lead to breakdowns and inefficiencies. Investing in training for operators can prevent common failures. Creating a culture of quality control within the team will also enhance performance.

This chart illustrates the production output of high-frequency welded steel pipe making machinery over four quarters. As the data shows, there is a significant increase in output from Q1 to Q4, indicating improved efficiency and performance in the welding process.

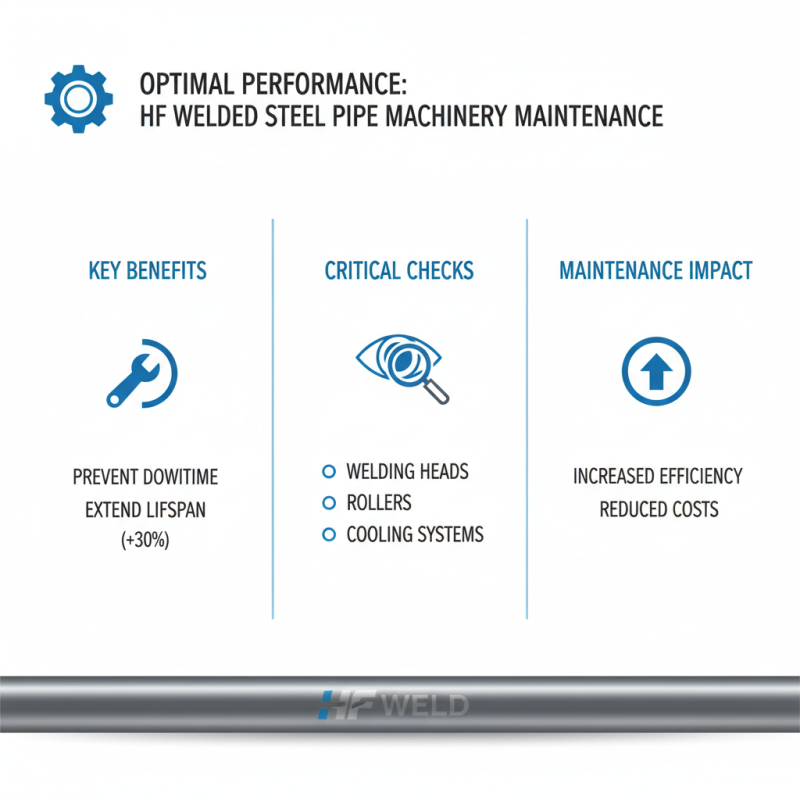

Maintaining high frequency welded steel pipe making machinery is crucial for efficiency. Regular checks on key components can prevent costly downtime. According to industry reports, routine maintenance can increase machinery lifespan by up to 30%. Inspecting the welding heads, rollers, and cooling systems often enhances their functionality.

Lubrication is essential. Regularly apply the right lubricants to moving parts. This simple task can lead to smoother operation, minimizing friction. The right lubricant can improve performance by 15%, according to equipment studies. However, many operators overlook this step, leading to premature wear and tear.

Additionally, operators should monitor electrical connections. Loose or corroded connections can cause malfunctions. In fact, around 20% of equipment failures stem from electrical issues, as highlighted in maintenance audits. Regular testing can reveal hidden problems before they escalate. Ignoring signs of wear can lead to larger, unexpected expenses.

Quality control is crucial in high-frequency welded pipe manufacturing. According to industry reports, around 20% of production defects stem from improper welding techniques. Effective quality control measures can significantly reduce this figure. Regular inspections and non-destructive testing methods, such as ultrasonic testing, are vital. These methods help detect internal flaws that may not be visible externally. Many manufacturers have achieved a defect rate below 1% by implementing rigorous quality protocols.

Tips for maintaining quality include providing consistent training for machine operators. Skilled operators can identify issues early. Implementing a preventive maintenance schedule also plays an important role. Regularly servicing machines can prevent unexpected breakdowns. Additionally, using high-quality raw materials is another key aspect. Poor quality materials can undermine the entire manufacturing process.

Staying updated with industry standards is essential. Remarks from recent reports indicate that companies adhering to ISO certifications see a 30% reduction in compliance issues. However, achieving and maintaining these standards can be challenging. Many manufacturers face resource constraints, which can lead to lapses in quality assurance. Continuous improvement in practices and technology adaptation is necessary for success.