In the dynamic landscape of modern manufacturing, enhancing production efficiency is paramount for companies aiming to remain competitive. The adoption of advanced technologies such as the "High Frequency Pipe Making Machine" has revolutionized the pipe manufacturing industry, optimizing processes and significantly reducing operational costs. According to a recent industry report by Grand View Research, the global pipe market is anticipated to reach USD 200 billion by 2025, highlighting the growing demand for efficient production techniques. Furthermore, with the increasing emphasis on sustainability and energy-efficient manufacturing, companies that implement high-frequency welding technology can achieve up to a 30% reduction in energy consumption, as noted by the American Welding Society. This blog delves into the multifaceted benefits of employing High Frequency Pipe Making Machines to boost production efficiency, ultimately contributing to improved profitability and market responsiveness.

High Frequency Pipe Making Machines are essential in modern manufacturing, particularly in the production of steel pipes. These machines utilize high-frequency induction technology to weld metal strips together, creating durable pipes used in various applications such as construction, oil transmission, and infrastructure development. By understanding the basic workings of these machines, manufacturers can significantly enhance their production efficiency and output quality.

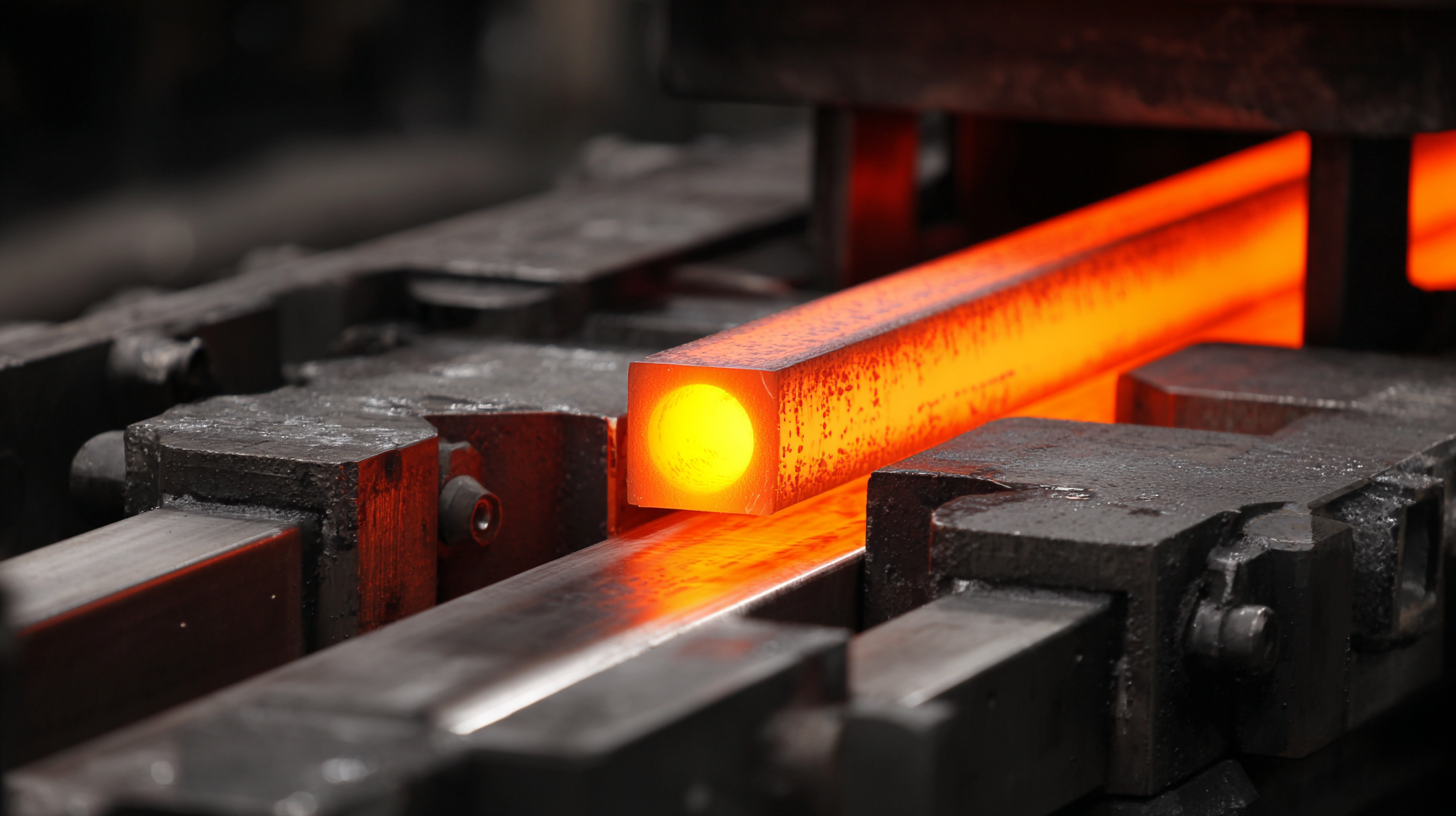

At the core of high frequency pipe making machines is their ability to produce pipes at a rapid rate while maintaining precision. The process begins with feeding flat steel strips into the machine, where they are formed into a pipe shape. The edges of the strips are then heated using high-frequency current, allowing for quick and effective welding. This technique not only speeds up the production process but also reduces the need for extensive post-welding treatments. By mastering the operation of these machines, manufacturers can effectively manage production schedules and reduce material wastage, leading to cost savings and increased profitability.

High frequency pipe making machines are revolutionizing the pipe manufacturing industry,

significantly enhancing production efficiency. One of the key features that contributes to this efficiency is the machine's ability to produce high-quality pipes at a faster rate. High frequency technology allows for rapid welding and forming processes, reducing lead times and increasing overall output. This is particularly important in the growing PVC pipe market, which includes various types such as PVC schedule 40, schedule 80, and drainage pipes.

To further leverage the capabilities of high frequency pipe making machines, manufacturers can focus on optimizing their production parameters. For instance, adjusting the welding speed and temperature settings can lead to better pipe consistency and strength. Additionally, regular maintenance of the machinery ensures that it operates at peak performance, minimizing downtime and maximizing productivity.

Another vital aspect is employee training. Investing in the workforce by providing comprehensive training on the operation of high frequency machines can greatly enhance production efficiency. Knowledgeable operators are crucial for troubleshooting and optimizing machine settings, ultimately leading to a smoother production process. By focusing on these elements, pipe manufacturers can position themselves for success in a competitive market.

Efficiency in production processes has become indispensable, particularly in industries utilizing high-frequency pipe making machines. To optimize workflow, it is essential to adopt best practices that streamline operations and enhance performance. Advanced machine learning algorithms, similar to those utilized in the analysis of high-dimensional gene expression data, can be applied to monitor and optimize production parameters in real-time. For instance, adaptive control systems can utilize data analytics to adjust parameters automatically, ensuring consistent product quality and reducing material waste.

Incorporating ensemble inference techniques, which have shown promise in proteomics, can further enhance the capabilities of production workflows. By integrating results from various operational workflows, manufacturers can achieve a broader understanding of process variances and strengths. Reports indicate that businesses implementing such optimized techniques have seen up to a 30% increase in throughput and a significant reduction in downtime. Additionally, continual validation of production processes through data-driven methods enables companies to maintain industry standards and adapt swiftly to market demands.

To ensure the longevity and efficiency of high-frequency pipe making machines, regular maintenance is crucial. First, operators should conduct daily checks, which include inspecting the machine’s electrical components and hydraulic systems for any signs of wear or damage. Additionally, it's essential to clean the machine regularly to prevent buildup of debris and dust, which can interfere with performance. By adhering to a daily maintenance routine, minor issues can be identified and resolved promptly before they escalate into costly repairs.

Incorporating scheduled maintenance around specific operational hours can also greatly enhance the lifespan of pipe making equipment. This includes lubrication of moving parts, tightening of loose bolts, and replacing worn-out filters. Furthermore, operator training plays a vital role in maintenance; ensuring that team members understand the machine operations thoroughly can help in avoiding common operational mistakes that lead to premature wear. By implementing these maintenance tips, businesses can significantly improve the operational efficiency of their high-frequency pipe making machines, ultimately leading to increased production output and reduced downtime.

The use of high frequency pipe making machines has revolutionized the manufacturing industry, with remarkable success stories demonstrating their impact on production efficiency. For instance, a case study from a leading pipe manufacturer in the United States showed a 30% increase in output after integrating a high frequency system. These machines not only enhance speed but also improve precision, leading to significant savings in material costs. Industry reports suggest that optimizing pipe production with high frequency technology can reduce labor costs by up to 25%.

When considering the implementation of high frequency pipe making solutions, it is crucial to assess the specific needs of your production line. **Tip 1**: Conduct a thorough analysis of your current processes to identify bottlenecks that high frequency machines can address. Investing in proper training for your workforce is equally vital, as skilled operators can maximize the capabilities of these machines. **Tip 2**: Collaborate with the equipment supplier to facilitate customized solutions that fit your production workflow.

Additionally, monitoring performance metrics after installation can help fine-tune operations. **Tip 3**: Set up key performance indicators (KPIs) to measure efficiency gains, waste reduction, and overall productivity. This data will provide invaluable insights for future investments and continuous improvement strategies.

| Case Study | Implementation Year | Production Efficiency Increase (%) | Monthly Production Volume (Tons) | Notable Improvements |

|---|---|---|---|---|

| Case Study A | 2020 | 30 | 1000 | Reduced scrap rate, improved material utilization |

| Case Study B | 2021 | 25 | 800 | Shortened production cycle time, enhanced product quality |

| Case Study C | 2022 | 35 | 1200 | Increased automation, reduced labor costs |