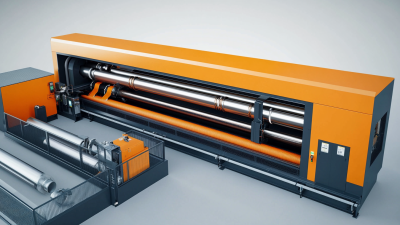

In the modern manufacturing landscape, achieving efficient production processes is crucial for sustaining competitive advantage, particularly in the tube production industry. One innovative solution that has emerged is the High Frequency Tube Mill Making Machine. This advanced machinery not only enhances the precision and quality of tube manufacturing but also significantly increases production speed, enabling manufacturers to meet rising market demands effectively.

By leveraging the capabilities of high frequency technology, producers can optimize their operations, reduce waste, and improve overall productivity. In this article, we will explore the best practices and strategies for utilizing High Frequency Tube Mill Making Machines to maximize efficiency, address common challenges, and ensure a seamless production workflow. Whether you are looking to upgrade your existing equipment or starting a new production line, understanding the potential of these machines is vital for thriving in today’s competitive environment.

By leveraging the capabilities of high frequency technology, producers can optimize their operations, reduce waste, and improve overall productivity. In this article, we will explore the best practices and strategies for utilizing High Frequency Tube Mill Making Machines to maximize efficiency, address common challenges, and ensure a seamless production workflow. Whether you are looking to upgrade your existing equipment or starting a new production line, understanding the potential of these machines is vital for thriving in today’s competitive environment.

High frequency tube mill technology has revolutionized the production of steel pipes, particularly in enhancing efficiency and quality in manufacturing processes. The principle of using high frequency welding not only speeds up production but also optimizes the mechanical properties of the pipes, thanks to the skin and proximity effects that are effectively harnessed during the welding process. Recent advancements indicate that implementations of innovative machinery, such as the latest high-frequency tube welding systems, have led to significant reductions in production time while maintaining the structural integrity of the products.

The global market for seamless and welded steel pipes is witnessing robust growth, with reports indicating increases in investments aimed at capacity expansion in major manufacturers. For instance, companies in the sector are investing substantially to upgrade their production technologies, which is crucial in a landscape identified by ongoing technological revolutions. These advancements are critical as they align with the broader trends of mass flourishing driven by industrial innovations, with sector players adopting modern automation and inspection systems to drive efficiency and ensure quality control in tube production processes. Integrating laser-based monitoring and novel welding techniques stands to further enhance production capabilities in the competitive pipe manufacturing industry.

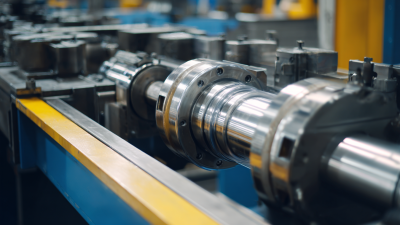

Achieving efficient production with high frequency tube mill making machines hinges on understanding and optimizing their key components. These machines typically consist of critical elements such as high-frequency induction welders, precision roll tooling, and effective cooling systems. Each component plays a significant role in ensuring consistent quality and optimal performance during the production process. By leveraging advanced technologies such as machine learning, manufacturers can further enhance the effectiveness of these components, leading to improved production efficiency and lower operational costs.

**Tips:** To enhance the efficiency of your high frequency tube mill, consider regular maintenance of the welding equipment and tooling, as their performance directly affects the output quality. Additionally, implementing predictive maintenance technologies can help detect potential issues before they disrupt production. Staying updated on innovations in energy-efficient practices can also lead to significant improvements in operational effectiveness.

The integration of modern data analysis techniques can streamline the operational workflows in tube mill production. By analyzing vibration signals and operational metrics, manufacturers can identify areas for improvement and refine their processes. This data-driven approach not only extends the lifespan of critical machinery but also supports the development of sustainable practices in manufacturing, ultimately contributing to a more eco-friendly production environment.

Efficient operation of high-frequency tube mills is essential for manufacturers aiming to maximize production while minimizing waste. According to a report by MarketsandMarkets, the global tube manufacturing market is projected to reach $65 billion by 2025, driven largely by advancements in technologies such as high-frequency welding. To achieve optimal productivity, it is crucial to focus on best practices in operating these machines.

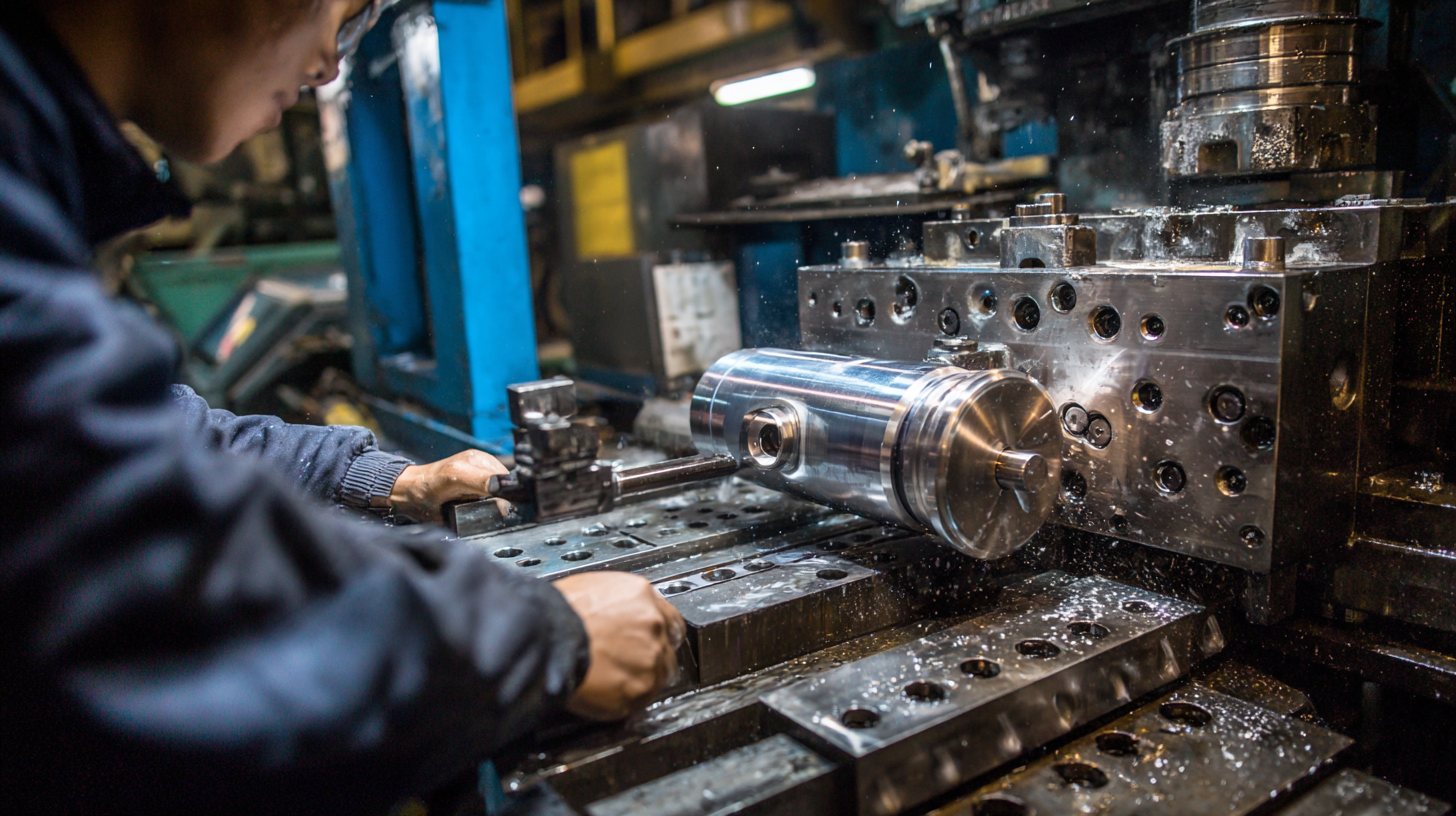

Regular maintenance schedules can improve output quality and reduce machine downtime, as each hour of unplanned downtime can cost manufacturers thousands in potential revenue.

Moreover, precision in setup and calibration significantly influences the operational efficiency of high-frequency tube mills. Studies indicate that improper alignment can lead to increased discrepancies in tube dimensions, waste, and defective units. Utilizing laser alignment tools, for instance, can enhance setup accuracy and ensure consistent production quality. Additionally, integrating automated controls for monitoring temperature and pressure during the welding process can further streamline operations. By adhering to these best practices, manufacturers not only enhance production efficiency but also ensure adherence to stringent quality standards increasingly demanded by the market.

In order to achieve high performance in tube mill operations, optimizing maintenance strategies is crucial. Regular and systematic maintenance ensures that machinery runs smoothly and efficiently, thus minimizing downtime and production losses. Implementing a proactive maintenance schedule allows operators to identify potential issues before they escalate, ensuring that the tube mills continue to perform at their best.

**Tips:** Schedule regular inspections to check for wear and tear on key components. Keeping a detailed log of maintenance activities helps track equipment performance trends, allowing for timely interventions. Additionally, investing in training for operators on proper handling and maintenance procedures can significantly enhance machine longevity.

Moreover, integrating advanced monitoring technologies can provide real-time data on machine conditions, enabling predictive maintenance. This approach reduces unexpected failures and ensures that machinery operates at optimal levels. By leveraging these strategies, manufacturers can enhance production efficiency while maintaining high-quality outputs from their high-frequency tube mill making machines.

**Tips:** Utilize sensor technology to monitor critical parameters like temperature and vibration, which can indicate impending failures. Creating a culture of maintenance awareness among the workforce fosters a sense of responsibility and encourages prompt reporting of any irregularities.

Investing in high frequency tube mill machines can yield substantial returns, particularly when evaluating their efficiency in production. These machines enhance the manufacturing process through rapid operation, resulting in higher output and reduced labor costs. The ability to produce a variety of tube sizes and specifications further strengthens their appeal in a competitive market, as businesses can quickly adapt to changing customer demands without significant downtime.

When assessing ROI for high frequency tube mill machines, it is crucial to consider the long-term benefits beyond initial costs. Factors such as energy consumption, maintenance expenses, and the potential for technological upgrades play a significant role in determining overall profitability. A comprehensive analysis that projects future savings and increased sales can provide a clearer picture of the investment's value, allowing companies to make informed decisions about integrating these advanced machines into their production lines.

| Machine Model | Production Rate (pcs/hr) | Power Consumption (kWh) | Initial Investment ($) | Annual Maintenance ($) | Expected ROI (%) |

|---|---|---|---|---|---|

| HFTM-1000 | 120 | 30 | 150,000 | 5,000 | 35 |

| HFTM-2000 | 150 | 40 | 180,000 | 6,000 | 34 |

| HFTM-3000 | 200 | 50 | 220,000 | 8,000 | 40 |

| HFTM-4000 | 250 | 60 | 270,000 | 10,000 | 42 |