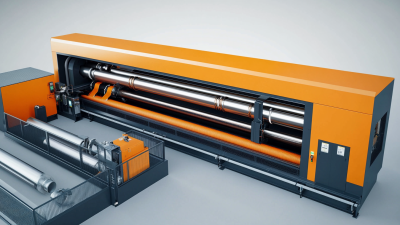

In today's fast-paced industrial landscape, the demand for precision and efficiency has never been greater, particularly in the pipe manufacturing sector. High Frequency Pipe Welding Machines have emerged as transformative tools that significantly enhance production speed and quality. According to a recent market report by Grand View Research, the global market for pipe welding machinery is expected to reach $5.3 billion by 2025, driven by advancements in technology and an increasing need for durable piping solutions. These machines not only reduce production time but also minimize material waste, resulting in lower operational costs—key factors that contribute to a competitive edge for manufacturers. As industries continue to evolve, the adoption of High Frequency Pipe Welding Machines will be crucial for businesses aiming to meet rising demands while optimizing their efficiency.

High frequency pipe welding machines are revolutionizing the manufacturing industry with their remarkable efficiency. A standout feature of these machines is their ability to weld pipes at speeds significantly faster than traditional methods. This acceleration not only boosts productivity but also reduces labor costs, allowing companies to allocate resources more effectively.

Another key feature is the precision offered by high frequency welding technology. The machines employ advanced control systems to ensure consistent and accurate welds, minimizing the risk of defects and rework. This enhances the structural integrity of the pipes and contributes to overall quality assurance in production lines.

**Tip:** When selecting a high frequency pipe welding machine, prioritize models with adjustable frequency settings. This flexibility allows operators to tailor their welding processes based on specific material types and thicknesses.

Furthermore, these machines often come with integrated safety features, ensuring a secure working environment. Investing in a machine with built-in sensors can alert operators to potential issues before they escalate, preventing costly downtimes.

**Tip:** Regular maintenance and training for operators can greatly extend the lifespan of your equipment and optimize performance. Always consult the manufacturer’s guidelines for best practices.

High frequency pipe welding technologies have revolutionized the manufacturing landscape by providing a competitive edge over traditional welding methods. One of the most notable advantages of high frequency welding is its ability to produce strong, consistent welds at a significantly faster rate. While traditional welding methods may involve multiple passes, high frequency welding accomplishes seamless joints in a single operation, minimizing labor costs and increasing throughput. This efficiency not only saves time but also reduces the overall energy consumption during the welding process.

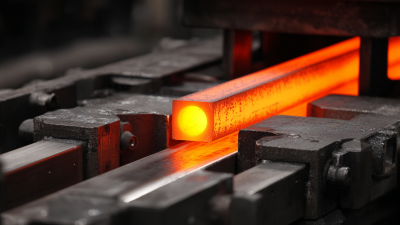

In contrast, traditional welding techniques often require complex setups and longer cooling periods between welds, which can lead to production bottlenecks. High frequency machines utilize advanced technology that allows for rapid heating and cooling, ensuring that the integrity of the material is maintained while achieving high-quality joints. Furthermore, the precision offered by high frequency welding reduces the likelihood of defects, resulting in fewer rework and scrap rates. This comparison highlights a clear trend towards adopting high frequency welding in industries that prioritize both efficiency and quality, setting a new standard in pipe manufacturing.

Investing in high-frequency pipe welding machines has become a pivotal strategy for companies aiming to optimize their manufacturing processes and reduce costs. According to a recent report by the International Welding Institute, industries utilizing high-frequency welding have reported a 30% increase in production efficiency compared to traditional welding methods. This efficiency translates into significant savings, as faster processing times reduce labor costs and increase throughput. Moreover, high-frequency welding machines have been shown to consume 15-20% less energy than their conventional counterparts, further enhancing their cost-effectiveness.

In addition to operational savings, the long-term financial benefits are substantial. A study by the American Welding Society highlights that organizations investing in high-frequency technology experience an average return on investment (ROI) of 150% within three years. This impressive ROI can be attributed to lower overall production costs, decreased material wastage, and reduced downtime due to maintenance. As the market trends toward more sustainable and efficient manufacturing practices, companies that implement high-frequency welding will not only gain a competitive edge but will also align themselves with future industry standards and expectations.

| Dimension | Value | Description |

|---|---|---|

| Initial Investment | $150,000 | Cost of high frequency welding machine and setup |

| Operational Cost | $30/hour | Average cost of electricity and labor |

| Production Efficiency | 40 pipes/hour | Number of pipes produced per hour |

| Material Waste | 5% | Percentage of material wasted during production |

| Return on Investment (ROI) | 25% | Estimated ROI over 3 years |

| Maintenance Cost | $5,000/year | Annual maintenance cost for the machine |

| Lifespan of Machine | 10 years | Expected lifespan with proper maintenance |

| Market Demand | High | Current demand for high frequency welded pipes |

In the modern landscape of pipe welding, performance metrics such as speed and quality are paramount. High frequency pipe welding machines exemplify efficiency, significantly enhancing output rates while maintaining the integrity of weld joints. Studies indicate that optimal welding parameters, including speed adjustments and controlled heat input, can minimize defects and ensure consistent quality across varying pipe materials. For instance, the mechanical properties of metals are crucial when addressing the challenges of dissimilar metal welding, like austenitic stainless steel and low-carbon steel, underscoring the importance of tailored welding approaches.

Moreover, advancements in technology, such as the implementation of automatic speed and torque adjustments in equipment, have revolutionized pipe welding practices. The ability to dynamically manage welding conditions allows for real-time optimizations, significantly impacting the microstructure and mechanical properties of welds. Recent research highlights the effectiveness of machine vision systems for monitoring molten pool behavior during gas metal arc welding, paving the way for smarter, data-driven solutions that enhance production efficiency and quality assurance in pipe welding operations. The continuous evolution in welding technology and process optimization is vital for manufacturers aiming to improve yield and lower operational costs in today's competitive market.

The adoption of high-frequency welding technology is witnessing a significant upswing across various industries, primarily driven by the growing demand for efficiency and precision in manufacturing processes. For instance, the industrial seam welder market is projected to expand from USD 1.2 billion in 2024 to USD 2.1 billion by 2033, marking a compound annual growth rate (CAGR) that speaks to the increased reliance on advanced welding techniques. High-frequency pipe welding machines, known for their speed and quality, are ideally positioned to meet the needs of industries such as construction and automotive, where robust and efficient welding processes are essential.

As industries innovate and embrace automation, the market trends indicate a burgeoning interest in integrating high-frequency welding solutions. Coupled with the rapid growth in the industrial robots sector, which is set to experience substantial advancements, the demand for high-frequency welding machines is likely to soar. Furthermore, sectors focusing on sustainability and next-generation power solutions are particularly inclined towards these technologies, aligning with broader market trajectories, such as the significant growth projected in the induction heating system market, expected to reach USD 17.61 billion. Thus, high-frequency pipe welding machines are poised to unlock competitive advantages across diverse industrial applications.