In the competitive world of manufacturing, efficiency is key. The "Custom Tube Mill Pipe Making Machinery" sector serves as a wellspring of innovation. Industry expert Mark Johnson states, “Efficiency in pipe production starts with the right machinery.” His insight reflects the pressing need for advanced technology in this field.

These machines are not just equipment but vital components of the manufacturing process. They shape the future of industries reliant on pipes. However, not all machinery performs equally well. Manufacturers often face struggles in optimizing performance and productivity.

Choosing the right custom tube mill can make a significant difference. It involves careful consideration of design specifications and operational capabilities. By investing in quality machinery, manufacturers can achieve superior output and reduce waste. Ultimately, it's about balancing cost and performance in an ever-evolving industry.

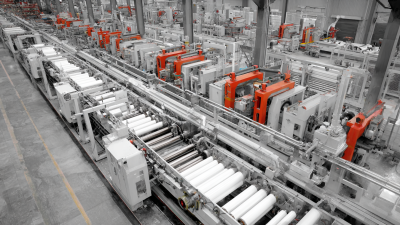

Custom tube mill technology plays a vital role in today's manufacturing landscape. It specializes in producing high-quality tubes and pipes tailored to meet specific requirements. Additionally, these mills enhance efficiency across various industries like automotive, construction, and energy. This technology allows for precise control over dimensions and wall thickness, which is critical for applications in piping systems.

The process itself involves several stages, including forming, welding, and finishing. Each stage adds complexity but also offers opportunities for improvements and innovations. Machines can be customized with different roll designs to fit unique applications, showcasing the adaptability of this technology. However, manufacturers often face challenges like maintaining consistent quality. Frequent adjustments might be needed to optimize production.

Moreover, the evolving demands of industries continuously require manufacturers to rethink their approaches. What works today may become outdated tomorrow. Embracing automation, for instance, presents benefits but also necessitates investment and continuous training. The pace of technological evolution keeps quality and efficiency at the forefront of discussions, prompting a need for ongoing reflection.

This chart illustrates the production efficiency percentages of the top 10 custom tube mill pipe making machinery, demonstrating their capabilities in efficient manufacturing processes.

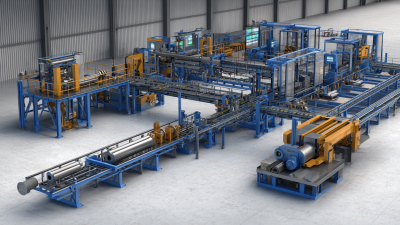

When selecting pipe making machinery, it's crucial to assess its key features. The build quality is a major consideration. A robust machine ensures durability and can handle varying production demands. Steel components often provide greater strength, while a well-designed structure prevents vibrations during operation.

Another vital aspect is the machine's flexibility. A versatile tube mill can produce different pipe sizes and shapes without extensive adjustments. This adaptability can significantly reduce downtime. Additionally, look for advanced control systems that allow for easy operator interaction. Intuitive interfaces can minimize training time and reduce potential errors.

Efficiency is always a focal point. An effective pipe-making machine should have high-speed operation without compromising quality. However, not all machines excel in this area. Sometimes, quicker production leads to defects that are costly. Pay attention to the machine's energy consumption as well. High efficiency in energy use can lead to long-term savings. It’s essential to balance speed, quality, and cost to find the right machine for your needs.

When it comes to custom tube mills, efficiency is key. These machines are designed to produce high-quality pipes for various applications. Each mill has unique specifications tailored to different manufacturing needs. Some mills offer rapid setup times, making them ideal for small production runs. Others excel in high-speed operations for larger volume requirements.

One notable feature of many tube mills is their ability to handle various materials. From mild steel to stainless steel, these machines can be versatile. However, not all tube mills are created equal. Some may struggle with thicker materials or specific shapes. This is something manufacturers must consider when selecting a mill. Fine-tuning the operating parameters is crucial for optimal performance.

Learning from experience is a vital part of improving manufacturing processes. Challenges may arise, such as inconsistent weld quality or machine downtime. Addressing these issues involves revisiting operational protocols and adjusting machine settings. Reflection on past production runs can lead to better outcomes in future operations. The focus should always be on continuous improvement and efficiency.

| Model | Pipe Size (mm) | Production Speed (m/min) | Power Requirement (kW) | Weight (kg) | Features |

|---|---|---|---|---|---|

| Model A | 20-50 | 30 | 75 | 1500 | High precision welding |

| Model B | 25-60 | 35 | 85 | 1600 | Adjustable roll configuration |

| Model C | 15-45 | 28 | 65 | 1400 | Automatic feeding system |

| Model D | 30-80 | 40 | 100 | 2000 | Integrated control system |

| Model E | 18-55 | 32 | 78 | 1550 | User-friendly interface |

| Model F | 22-65 | 37 | 90 | 1700 | High output efficiency |

| Model G | 28-70 | 45 | 110 | 1800 | Versatile for various pipe types |

| Model H | 20-60 | 50 | 95 | 1600 | Fast changeover systems |

| Model I | 25-65 | 42 | 88 | 1750 | Energy-efficient design |

| Model J | 18-50 | 30 | 70 | 1450 | Compact structure |

When exploring tube mill manufacturers, several key features distinguish the best from the rest. Leading manufacturers focus on efficiency, durability, and technology. They invest in automated systems that enhance precision. Many offer customization options to meet specific production needs. This flexibility can be crucial for various industries.

Tips: Always assess the after-sales support. A reliable manufacturer provides robust customer service. This can save time during upgrades or repairs. Additionally, consider the energy consumption of the machines. Higher efficiency translates to lower operational costs.

The comparison of leading manufacturers reveals gaps. Some may excel in technology but lack long-term reliability. Others may offer quality but at premiums that compromise accessibility. It’s important to weigh these aspects carefully. Often, buyers overlook the importance of maintenance ease. Machines that require frequent downtime can hinder production efficiency.

The evolution of tube manufacturing equipment is a fascinating journey. As industries seek greater efficiency, innovative trends emerge. Automation is a key driver. Machines now operate with precision, reducing human error. Advanced sensors monitor processes in real-time. This ensures quality control, but can sometimes lead to over-reliance on technology.

Another significant trend is the move towards sustainable practices. Equipment that uses less energy is in demand. Manufacturers are developing machines that reduce scrap material. The result is a lower environmental footprint. However, this transition is not always seamless. Some companies struggle to balance cost and eco-friendliness.

Customizable machinery is also gaining traction. Manufacturers can tailor equipment to their specific needs. This flexibility enhances production efficiency. Yet, it poses challenges too. Finding the right customization can be daunting. The industry's pace can pressure businesses to adapt quickly. Navigating these changes requires thoughtful consideration.