In the competitive world of manufacturing, the choice of machinery is crucial. Custom Tube Mill Pipe Making Machinery has gained popularity for its tailored capabilities. John Smith, an industry expert, notes, “The right machinery can transform production efficiency.”

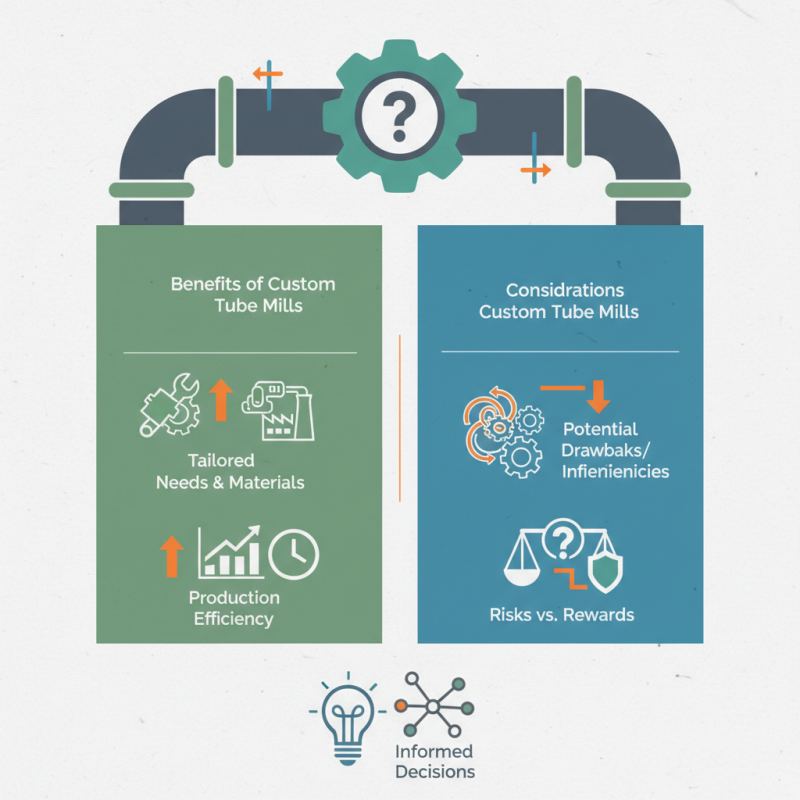

Investing in custom tube mills means considering specific needs. Each operation varies, so a one-size-fits-all approach might not yield the best results. Custom solutions often address unique challenges—be it material type or production volume.

However, not all manufacturers may realize the potential drawbacks. Selecting machinery without proper consultation can lead to inefficiencies. It’s essential to weigh the benefits of custom designs against potential risks. Understanding these nuances is fundamental for making informed decisions in this industry.

Custom tube mill pipe making machinery plays a crucial role in manufacturing various types of pipes. These machines are specifically designed to produce high-quality tubes efficiently. They can handle different materials, shapes, and sizes. This flexibility makes them essential for various industries. For instance, construction and automotive sectors rely heavily on custom pipe solutions.

Understanding how these machines operate is important. They utilize a series of rollers and welding techniques to form tubes from flat sheets of metal. Adjustments can be made to meet specific requirements. However, this customization can also complicate operations. Sometimes, fine-tuning the settings can lead to delays and added costs. It's essential to evaluate the production process carefully to avoid these pitfalls.

The choice of materials and design impacts the final product's quality and durability. Selecting the right specifications requires thoughtful consideration. Make sure to think about both immediate and long-term needs. Identifying potential challenges early can prevent future problems. Investing in custom tube mill pipe making machinery can offer significant advantages, but awareness of its complexities is also necessary.

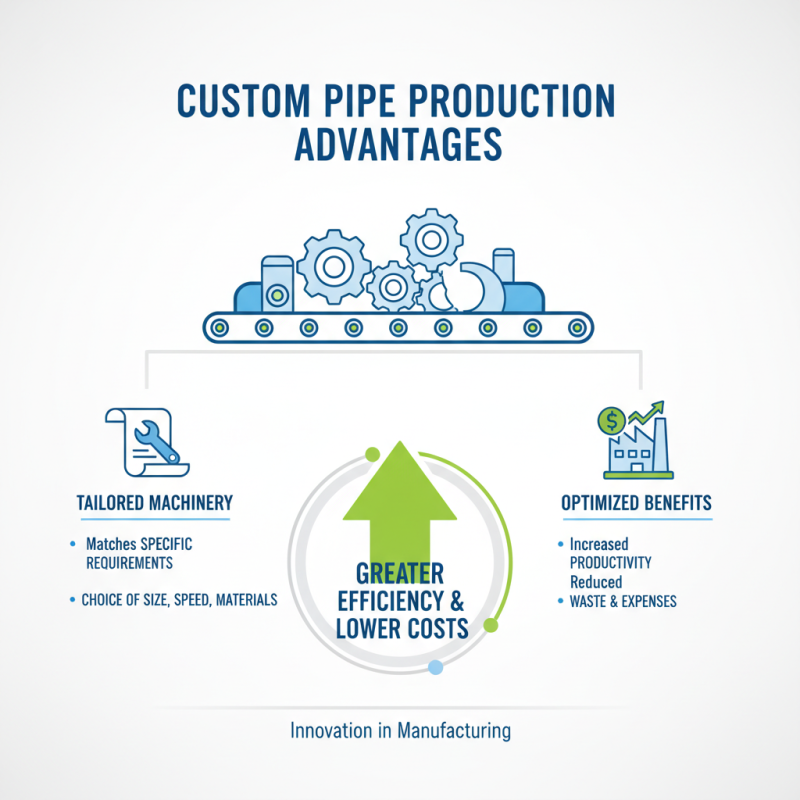

When it comes to pipe production, customization provides significant advantages. Custom tube mill pipe making machinery can be tailored to individual specifications. This ensures that the equipment meets specific production requirements. Manufacturers can choose the size, speed, and materials used. Such adaptability allows for greater efficiency and potentially lower costs.

Custom machinery also addresses unique industry needs. Each sector has different standards and expectations. A one-size-fits-all approach often falls short. Adjustments in machinery can lead to better product quality. Conversely, lack of customization might result in inefficient operations. Fitting equipment to exact needs reduces waste.

Investing in bespoke machinery can reflect a commitment to innovation. It shows a willingness to enhance production capabilities. However, custom solutions can come with higher initial costs. Companies must weigh these costs against potential long-term savings. It’s a balancing act that requires careful consideration. Custom solutions challenge businesses to rethink processes continually. Each decision points toward improving efficiency and production quality.

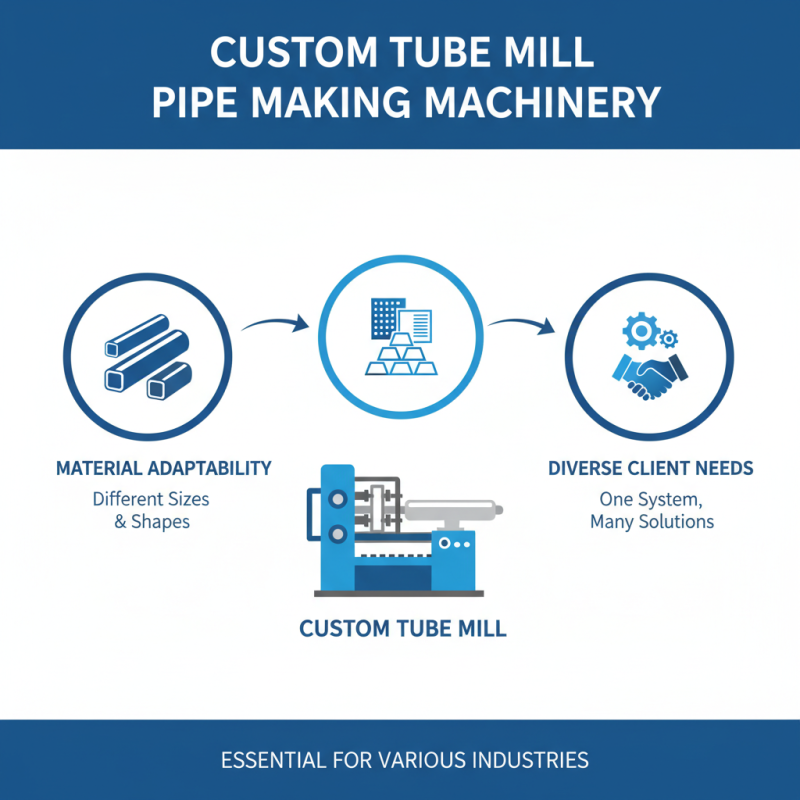

Custom tube mill pipe making machinery is essential for various industries. These machines offer versatility, allowing manufacturers to produce pipes of different sizes and shapes. One significant feature is their adaptability to various materials. Whether it’s stainless steel, aluminum, or carbon steel, a custom tube mill can handle it all. This capability ensures that businesses can meet diverse client needs without investing in multiple systems.

Another key aspect is the precision of the machinery. Tube mills are designed to achieve exact specifications. This leads to less waste and more efficient production processes. Operators often find that setting up these machines is straightforward. However, this doesn’t mean challenges won't arise. Inexperience can lead to errors, such as misaligned components or incorrect settings. Regular training is crucial, as it enhances skill levels and minimizes mistakes.

Moreover, the speed of production is impressive. A well-tuned tube mill can significantly reduce lead times. Yet, it’s essential to monitor the machinery closely. Overlooking maintenance can lead to breakdowns and downtime. Investing in high-quality components helps, but understanding their limitations is equally important. Balancing efficiency with a keen awareness of potential pitfalls is paramount for long-term success in pipe manufacturing.

When considering custom pipe making solutions, there are several key factors to keep in mind. The specific needs of your project are crucial. Size, shape, and material all play a significant role in the decision-making process. For instance, high-strength steel may be required for demanding applications. On the other hand, light materials could suffice for smaller projects. Each choice impacts overall performance and durability.

Quality and precision are paramount. A well-made tube mill can ensure consistency in production. This affects reliability and can reduce waste. However, not all machinery delivers the same level of accuracy. It's worth examining the manufacturing process. A blend of innovation and traditional techniques might be necessary. A deeper dive into the technology used often reveals the hidden advantages.

Cost considerations also warrant reflection. While it may be tempting to opt for the cheapest solution, long-term expenses matter too. Maintenance and operational costs should be factored in. Sometimes, a higher upfront investment results in savings down the line. Evaluating the total cost of ownership can provide clearer insights. Balancing these elements requires careful thought and thorough research.

Custom tube mills have transformed many industries. These machines produce pipes and tubes tailored to specific needs. One example is the automotive sector. Manufacturers create lightweight tubes that improve fuel efficiency. Custom designs allow for unique shapes and sizes that fit specific vehicle models perfectly. However, not every application finds success. Some projects face design challenges.

Another interesting case is in construction. Companies utilize custom tube mills to fabricate structural components. This enhances strength and reduces material wastage. These efficiencies can significantly impact a project’s timeline and budget. Still, reliance on custom machinery has risks. Not all designs are feasible within budget constraints.

A success story involves a medical equipment manufacturer. They required specialized tubing for new devices. Custom tube mills provided the exact specifications, resulting in improved product performance. Yet, they faced difficulties during initial production runs. Issues with tolerances delayed the project. Continuous refinement led to eventual success, demonstrating the importance of adaptation.