Choosing the right equipment for your production needs is crucial, especially in a competitive landscape where efficiency and quality make all the difference. In this ultimate guide, we will explore the essential factors to consider when selecting a Carbon Steel Tube Mill Pipe Making Machine. As industries increasingly demand durable and high-quality steel products, having the right machinery can streamline your operations and enhance output.

From understanding the various specifications to evaluating your production requirements, this guide will provide valuable insights to help you make an informed decision. Whether you are a seasoned manufacturer or new to the field, our comprehensive overview will equip you with the knowledge to optimize your investment and ensure that your pipe-making processes meet both industry standards and customer expectations.

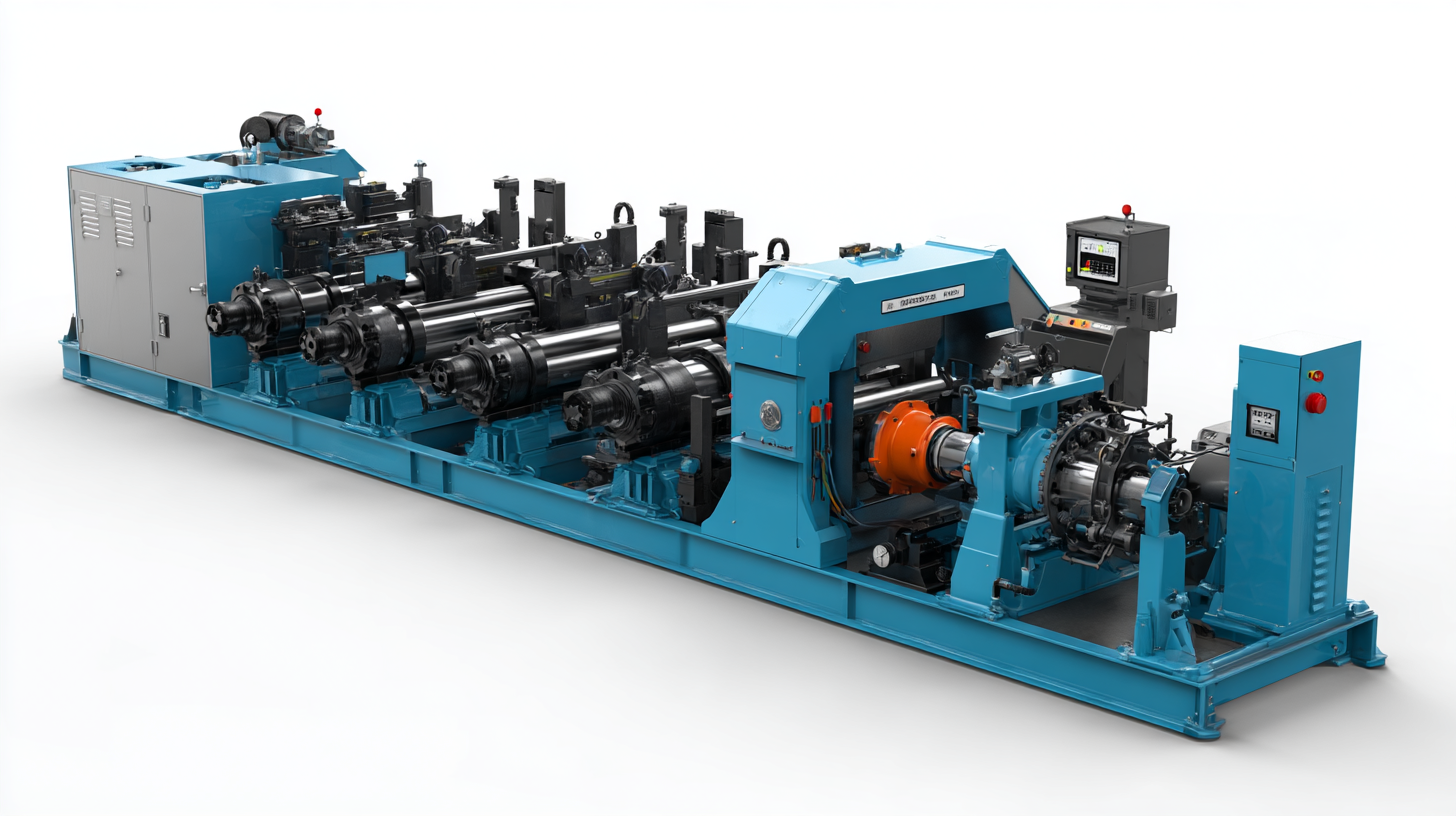

When selecting a carbon steel tube mill for your operation, several critical factors must be considered to ensure optimal production efficiency. First, assess the machine's capabilities in terms of pipe diameter and wall thickness. According to a recent market report by MarketsandMarkets, the demand for carbon steel pipes is projected to grow at a CAGR of 5.2% from 2021 to 2026, indicating a need for mills that can handle a variety of specifications. Having a mill that can adapt to changing market demands will enhance your business's flexibility.

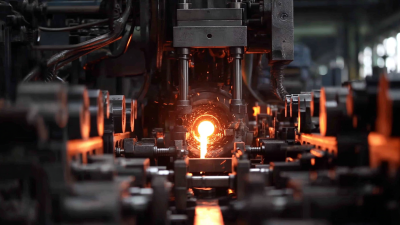

Another important consideration is the technology and automation features of the machine. Advanced tube mills equipped with automated controls can significantly reduce production time and improve product consistency. The International Trade Association notes that manufacturers using advanced technologies can increase their output by 30%, thereby reducing labor costs and minimizing waste. Investing in a high-quality machine with the latest technology ensures not only efficiency but also competitiveness in a rapidly evolving industry.

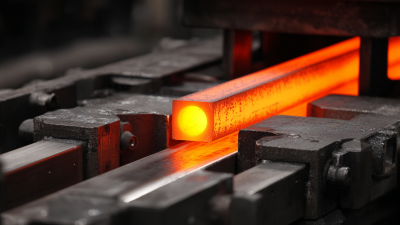

When it comes to selecting a carbon steel tube mill machine, understanding the different types available is crucial for optimizing your production needs. There are several categories of machines, each designed for specific applications. For instance, a high-frequency welded tube mill is excellent for producing thin-walled tubes at high speeds, making it ideal for industries like HVAC and furniture. On the other hand, the spiral welded tube mill is suited for larger pipes and can accommodate heavier wall thicknesses, which is beneficial for construction and infrastructure projects.

**Tip:** Evaluate your product specifications and production capacity before making a decision. Consider how the machine's speed and capabilities align with your output goals.

Moreover, features like automation, ease of maintenance, and energy efficiency should also be part of your evaluation. For example, a machine equipped with advanced control systems can reduce downtime and increase productivity through streamlined operations. Furthermore, incorporating energy-efficient models not only reduces operational costs but also aligns with sustainability goals.

**Tip:** Don't hesitate to ask manufacturers about their machine's support and upgradeability options to ensure long-term reliability and efficiency.

| Machine Type | Production Speed (m/min) | Pipe Diameter Range (mm) | Wall Thickness Range (mm) | Energy Consumption (kW) | Price Range (USD) |

|---|---|---|---|---|---|

| Standard Tube Mill | 20-30 | 20-100 | 1.0-3.0 | 15-25 | 30,000-50,000 |

| High-Frequency Welded Tube Mill | 30-50 | 10-200 | 1.2-5.0 | 25-35 | 50,000-80,000 |

| Cold Drawn Tube Mill | 10-15 | 5-50 | 0.5-2.0 | 10-20 | 20,000-35,000 |

| Precision Tube Mill | 40-70 | 15-300 | 0.8-4.0 | 30-45 | 70,000-120,000 |

When selecting the right carbon steel tube mill pipe making machine, it's critical to analyze production capacity to ensure optimal alignment with your manufacturing needs. According to a report by American Metal Market, the demand for carbon steel pipe products has surged by 12% over the last year, making efficiency and capacity evaluation even more essential. Understanding your output requirements—whether you're aiming for small-batch or high-volume production—can directly influence your choice of machinery. A mill that produces at a capacity of 150 tons per day is optimal for moderate production needs, while a high-capacity mill, capable of outputting over 300 tons, may be better suited for larger operations.

Tip 1: Always consider your future production demands. If you anticipate growth, investing in a mill with expandable capacity can save costs in the long run.

It's also vital to assess the mill's efficiency rates and how they correlate with your operational capabilities. Research conducted by the Tube & Pipe Association indicates that mills operating above 85% efficiency can significantly reduce waste and increase profitability. Evaluate features like automation and speed to match your production line's velocity and throughput effectively.

Tip 2: Seek machines with advanced technology that offer real-time monitoring and data analytics. This can enhance maintenance schedules and production planning.

By carefully analyzing these elements, you can ensure your tube mill not only meets your current production needs but is also adaptable for future growth.

When selecting a carbon steel tube mill pipe making machine, it’s essential to focus on key features and technologies that align with your production needs. One critical aspect is the machine's efficiency, which directly influences your output and production costs. Look for machines equipped with advanced automation systems that reduce manual handling and improve precision in the manufacturing process. Additionally, advanced programmable logic controllers (PLCs) can enhance operational control and facilitate quick adjustments based on varying production requirements.

Another significant technology to consider is the material handling and feeding system. A high-quality feeding mechanism ensures seamless and consistent flow of raw materials into the machine, minimizing downtime and wastage. Furthermore, incorporating features like in-line inspection systems can enhance quality control, allowing for real-time monitoring of the finished pipes and ensuring they meet industry standards. By focusing on these key features, you can invest in a pipe making machine that not only meets your current production needs but also offers scalability for future growth.

When selecting a carbon steel tube mill pipe making machine, the decision often comes down to a cost-benefit analysis: investing in quality versus merely focusing on price. While it may be tempting to opt for the cheapest option available, a thorough evaluation of the long-term benefits of investing in a high-quality machine can reveal substantial advantages. Quality machines often have a longer lifespan, higher efficiency, and improved energy savings, which can lead to reduced operating expenses over time.

**Tips:**

1. Assess the total cost of ownership rather than just the initial purchase price. This includes maintenance, energy consumption, and potential downtime costs associated with lower-quality machines.

2. Research energy-efficient technologies that can be integrated into your production process. Even if the upfront costs are slightly higher, the savings in energy bills can quickly offset the difference.

3. Consider the reputation of the manufacturer. Reliable brands that focus on quality often provide better customer support and warranty options, enhancing your investment’s value.

By taking these factors into consideration, you can make a more informed decision that aligns with your production needs and financial objectives.